Ceramic electric heating assembly and method for manufacturing same

An electric heating and ceramic technology, which is applied in the field of ceramic electric heating components and its preparation, can solve problems such as complicated process, inconsistent resistance temperature drift, poor heat dissipation performance, etc., and achieve the effect of improving production efficiency, simplifying the preparation process, and good temperature consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

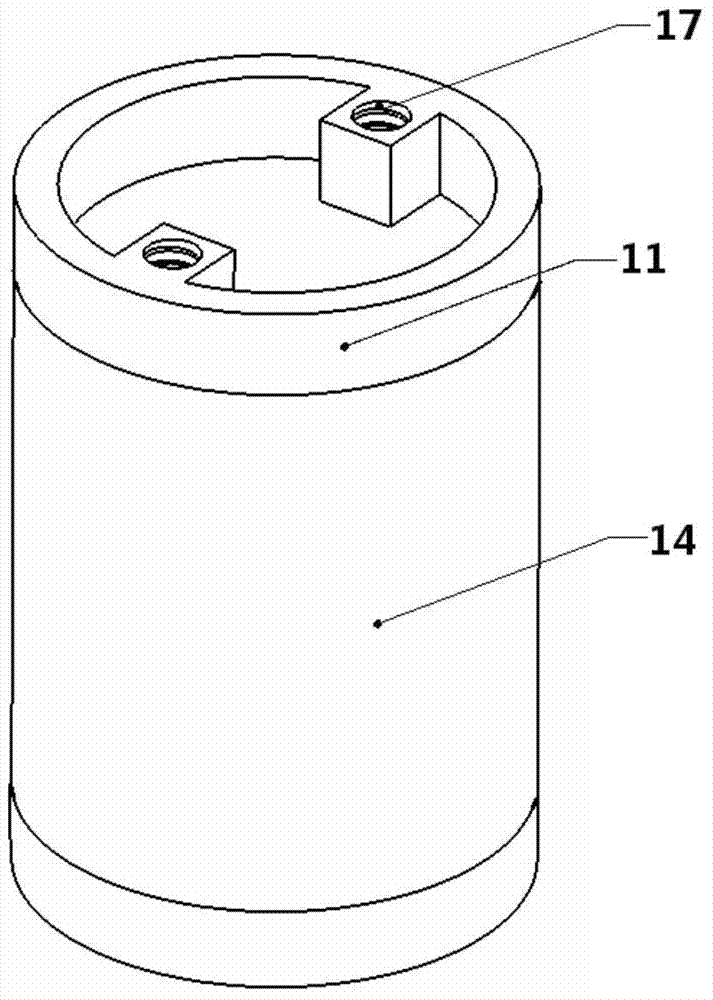

[0080] The invention also discloses a method for preparing a ceramic electric heating component, which includes the following steps:

[0081] (1) obtain the ceramic substrate with screw hole through forming;

[0082] (2) setting electrodes on the ceramic substrate, and the screw holes are electrically connected to the electrodes;

[0083] (3) Obtain the heating film resistor connected to the electrode and arranged on the ceramic substrate by thick film screen printing, film deposition or sputtering;

[0084] (4) A protective layer covering the resistor is formed on the ceramic substrate by thick-film silk screen printing to obtain a ceramic electric heating component.

[0085] According to the present invention, firstly, a ceramic matrix with screw holes is obtained by molding. The ceramic matrix is preferably alumina or aluminum nitride ceramics with a purity not lower than 95%. The ceramic substrate is preferably formed into a specific shape by casting, film pressing or...

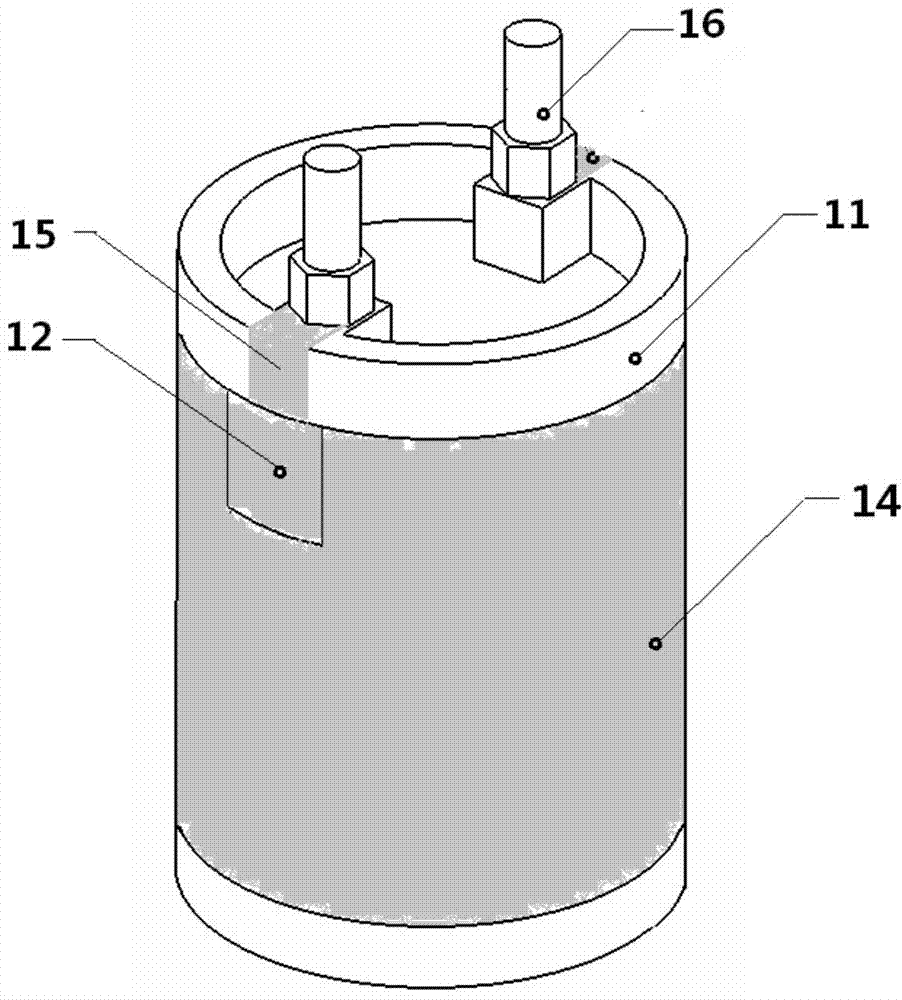

Embodiment 1

[0097] A cylindrical 95% alumina ceramic substrate is obtained by molding; two screw holes are arranged on the top surface of the ceramic substrate;

[0098]The electrode paste is printed on the side wall of the ceramic substrate and sintered at 850°C; the formed electrode and the screw hole are sintered to form a side conductive electrode, and the side conductive electrode makes the electrode and the screw hole electrically connected.

[0099] The prepared ruthenium oxide slurry is deposited on the side wall of the ceramic substrate by printing, and sintered in a tunnel furnace under 850°C clean air atmosphere to form a heating film resistor.

[0100] The glass paste is coated on the outer surface of the heating film resistor by printing, and sintered in a tunnel furnace at 600°C to obtain a protective layer.

[0101] Cut the cross-section of the resistor body by laser cutting the formed heating film resistor, and adjust the resistance value by reducing the cross-sectional ar...

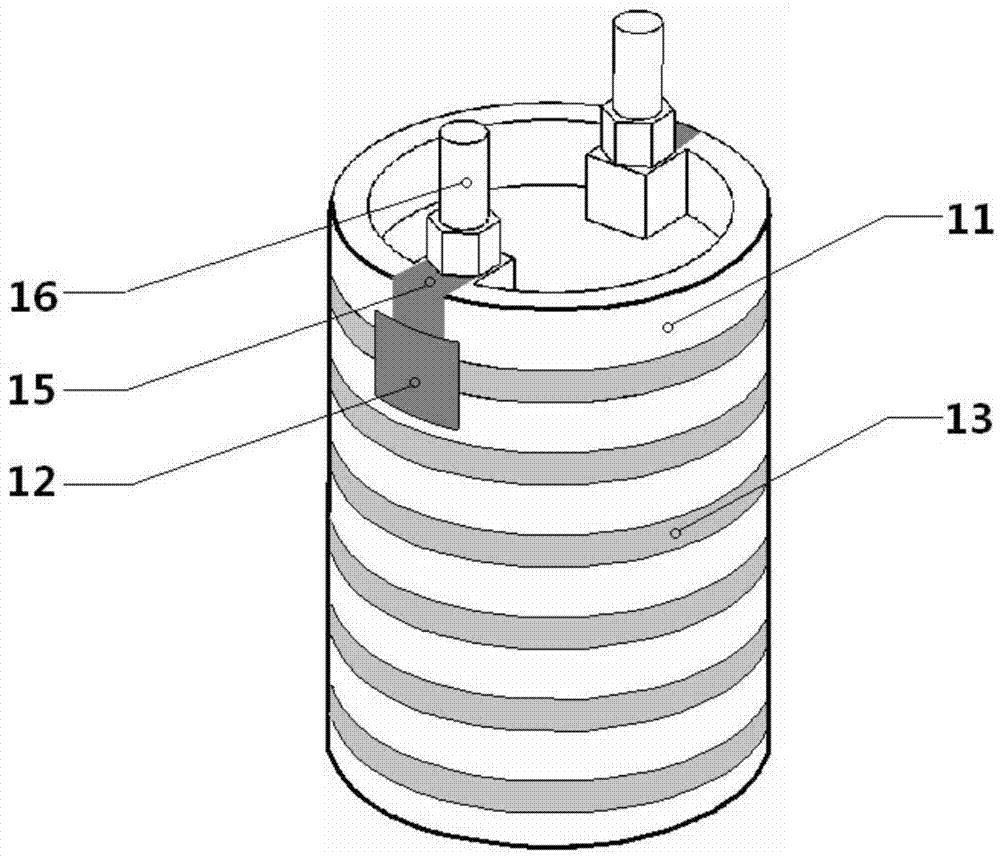

Embodiment 2

[0110] A cylindrical 95% alumina ceramic substrate is obtained by molding; two screw holes are arranged on the side of the ceramic substrate;

[0111] The electrode paste is printed on the side wall of the ceramic substrate and sintered in a 900°C tunnel furnace; the electrodes and the screw holes are electrically connected.

[0112] The prepared ruthenium oxide slurry was deposited on the side wall of the ceramic substrate by printing, and sintered in a tunnel furnace at 900°C to form a heating film resistor.

[0113] The glass paste is coated on the outer surface of the heating film resistor by printing and sintered at 600°C to obtain a protective layer.

[0114] Lead wires matching the screw holes are prepared, the two are connected by threads, and insulating sleeves are sheathed on the lead wires.

[0115] A graphene coating is coated on the bottom surface of the ceramic substrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com