Fiber-felt-reinforced composite material solar energy assembly frame and preparation method thereof

A technology of reinforced composite materials and solar modules, applied in electrical components, photovoltaic modules, photovoltaic power generation, etc., can solve the problems of complex process and low longitudinal strength, achieve excellent comprehensive performance, convenient and easy preparation method, and reduce quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The frame of the solar module of this embodiment is made by the following methods:

[0031] (1) Mix the additives with a content of 5% of the resin content, including curing agent, flame retardant, ultraviolet absorber, release agent, catalyst, etc., with 40 parts by mass of liquid polyurethane, and mechanically stir to obtain a uniform resin mixture;

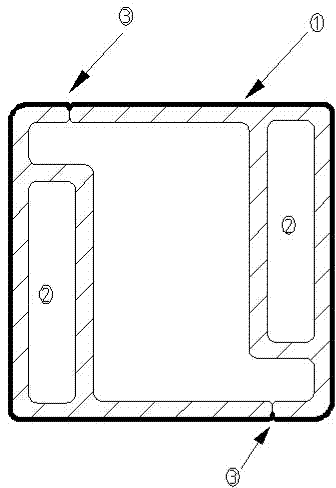

[0032] (2) Arranging the continuous glass fibers impregnated with the coupling agent and drying into a predetermined shape and impregnating them in a resin mixture containing additives; the predetermined shape of the continuous glass fibers arranged as shown in the attached figure 1 As shown, it is a regular shape formed by connecting two groups of solar module frames end to end; the mass fraction of the continuous glass fiber is 45 parts;

[0033] (3) Wrap glass fiber felt outside the continuous fiber impregnated with resin mixture; the mass fraction of said glass fiber felt is 15 parts;

[0034] (4) Obtain two end-to...

Embodiment 2

[0039] The frame of the solar module of this embodiment is made by the following methods:

[0040] (6) Mix additives with a content of 5% of resin content, including curing agent, release agent, catalyst, etc., with 35 parts by mass of liquid modified vinyl resin, and obtain a uniform resin mixture through mechanical stirring;

[0041] (7) arrange the continuous glass fibers impregnated with the coupling agent and dried into a predetermined shape and impregnate them in a resin mixture containing additives; the mass fraction of the continuous glass fibers is 50 parts;

[0042] (8) Wrap glass fiber felt outside the continuous fibers impregnated with resin mixture; the mass fraction of said glass fiber felt is 15 parts;

[0043] (9) Obtain two end-to-end solar module frames through the pultrusion process with the mold temperature at 130°C and the process parameters at the pultrusion speed of 1.5m / min;

[0044] (10) Cut and polish along the joint ③ of the frame of the two solar m...

Embodiment 3

[0047] The frame of the solar module of this embodiment is made by the following methods:

[0048] (1) Mix the additives with a content of 5% of the resin content, including curing agent, release agent, catalyst, etc., with 25 parts by mass of liquid epoxy resin, and obtain a uniform resin mixture through mechanical stirring;

[0049] (2) arrange the continuous glass fibers impregnated with the coupling agent and dried into a predetermined shape and impregnate them in a resin mixture containing additives; the mass fraction of the continuous glass fibers is 60 parts;

[0050] (3) Wrap glass fiber felt outside the continuous fiber impregnated with resin mixture; the mass fraction of said glass fiber felt is 15 parts;

[0051] (4) Obtain two end-to-end solar module frames through the pultrusion process with the mold temperature at 165°C and the process parameters at the pultrusion speed of 1.5m / min;

[0052] (5) Cut and polish along the joint ③ of the frame of the two solar modu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com