Method for steam explosion-sodium chlorite-alkali treatment combined preparation of cotton bast fibers

A technology of sodium chlorite and cotton stalk bark, which is applied in the chemical post-treatment of fibers, fiber treatment, textiles and papermaking, etc., and can solve problems such as fiber damage, large amount of alkali used in chemical methods, and thick fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

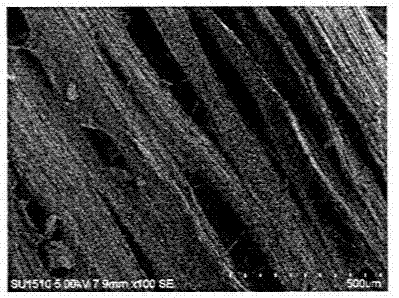

Image

Examples

Embodiment 1

[0028] (1) cutting: the cotton stalk bark is cut into 8cm long fragments;

[0029] (2) Soaking: place the cut cotton stalk skin in clear water with a solid-to-liquid ratio of 1:20, and soak for 12 hours;

[0030] (3) Steam flash explosion: put the soaked cotton stalks into the flash explosion tank, inject saturated water vapor, make the saturated water vapor pressure reach 2.0MPa, maintain the saturated water vapor pressure for 120s, and then flash instantly within 0.0875s ;

[0031] (4) Washing with hot water: wash the cotton stalk fiber after flash explosion in hot water at 90° C. for 1 hour, with a solid-to-liquid ratio of 1:40, filter through a sieve with an aperture of 20 mesh, and collect the cotton stalk fiber;

[0032] (5) Sodium chlorite treatment: use sodium chlorite solution to process the cotton stalk fiber obtained in step (4), the solid-to-liquid ratio is 1:30, the temperature is 70°C, the pH value is 3.5, and the sodium chlorite solution The mass percentage co...

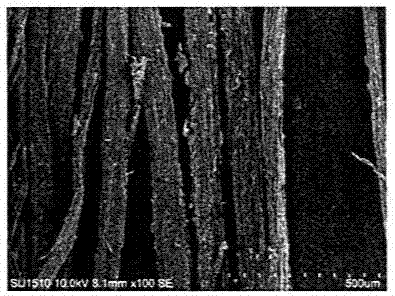

Embodiment 2

[0036] (1) cutting: the cotton stalk bark is cut into 9cm long fragments;

[0037] (2) Soaking: put the cut cotton stalk skin in clear water with a liquor ratio of 1:15, and soak for 18 hours;

[0038] (3) Steam flash explosion: put the soaked cotton stalks into the flash explosion tank, feed saturated water vapor to make the saturated water vapor pressure reach 1.7MPa, maintain the saturated water vapor pressure for 180s, and then flash instantly within 0.0875s ;

[0039] (4) Washing with hot water: wash the cotton stalk fiber after flash explosion in hot water at 85° C. for 1.5 h, with a solid-to-liquid ratio of 1:30, filter through a 20-mesh sieve, and collect the cotton stalk fiber;

[0040] (5) Sodium chlorite treatment: use sodium chlorite solution to process the cotton stalk fiber obtained in step (4), the solid-to-liquid ratio is 1:20, the temperature is 60°C, the pH value is 4, and the sodium chlorite solution The mass percentage concentration is 0.4%, and the cotto...

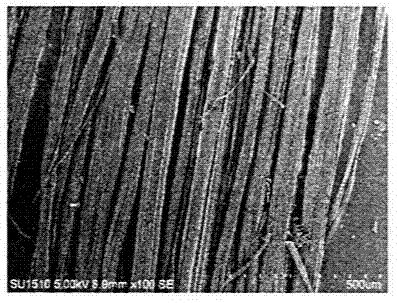

Embodiment 3

[0044] (1) cutting: the cotton stalk bark is cut into 10cm long fragments;

[0045] (2) Soaking: put the cut cotton stalk skin in clear water with a liquor ratio of 1:10, and soak for 24 hours;

[0046](3) Steam flash explosion: put the soaked cotton stalks into the flash explosion tank, feed saturated water vapor to make the saturated water vapor pressure reach 1.5MPa, maintain the saturated water vapor pressure for 180s, and then flash instantly within 0.0875s ;

[0047] (4) Washing with hot water: wash the cotton stalk fiber after flash explosion in hot water at 80° C. for 2 hours, with a solid-to-liquid ratio of 1:20, filter through a sieve with an aperture of 20 mesh, and collect the cotton stalk fiber;

[0048] (5) Sodium chlorite treatment: process the cotton stalk fiber obtained in step (4) with sodium chlorite solution, the solid-to-liquid ratio is 1:25, the temperature is 80°C, and the pH value is 4.5, which is sodium chlorite The mass percent concentration of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com