Template-free preparation method of hollow micro-spherical polymers with covalent organic frameworks (COFs)

A covalent organic framework and hollow microsphere technology, which is applied in the preparation of microspheres and microcapsule preparations, can solve the problems of low porosity and small pore size of COFs, and achieve the effects of short process, mild conditions and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] Preparation of ligand four-armed aldehyde:

[0016]

[0017] Take by weighing 2g (5.16mmol) of pentaerythritol bromide, 2.52g (20.6mmol) of 4-hydroxybenzaldehyde and 8.55g (61.9mmol) of anhydrous potassium carbonate, join in the anhydrous DMF of 30ml, heat up to 100 while stirring ℃, keep warm and stir vigorously for 72h, cool to room temperature, use a rotary evaporator to remove most of the DMF, and then add a large amount of ice water to dissolve the K 2 CO 3 , extracted the product several times with chloroform, and then washed repeatedly with ice water until the solution was a light yellow colorless transparent liquid. Most of the chloroform was rotary evaporated, and vacuum-dried to obtain the product four-arm aldehyde.

Embodiment 1

[0019]

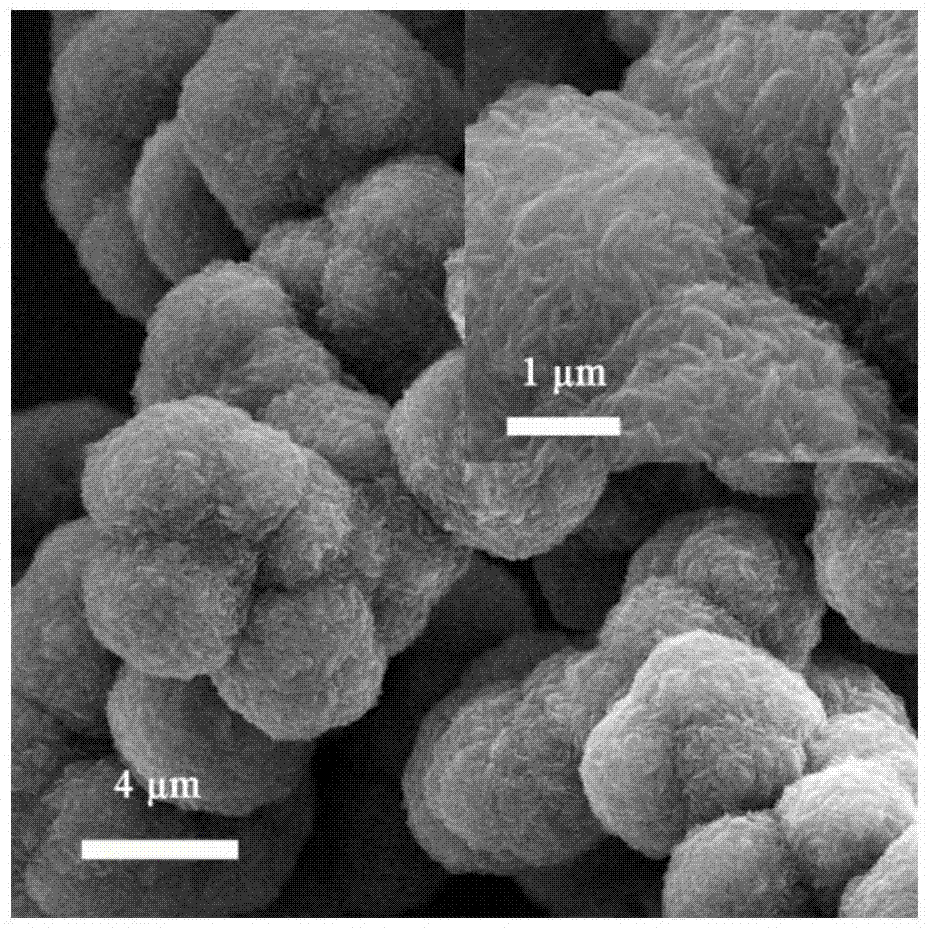

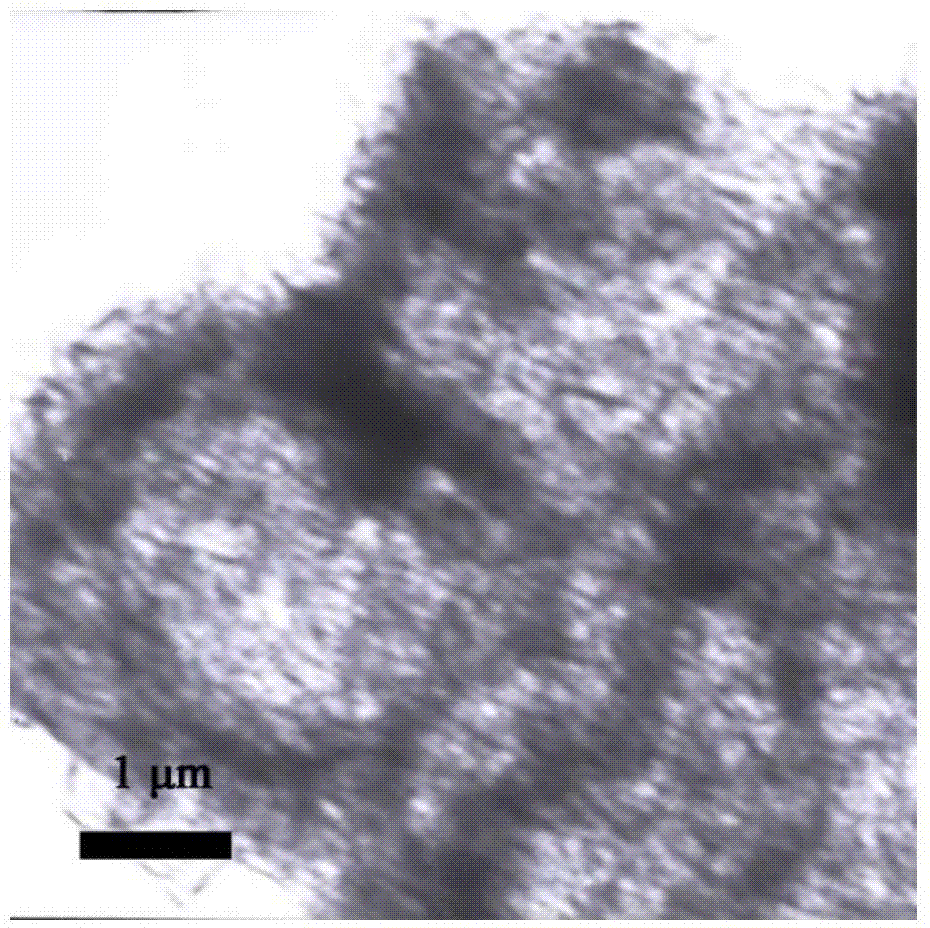

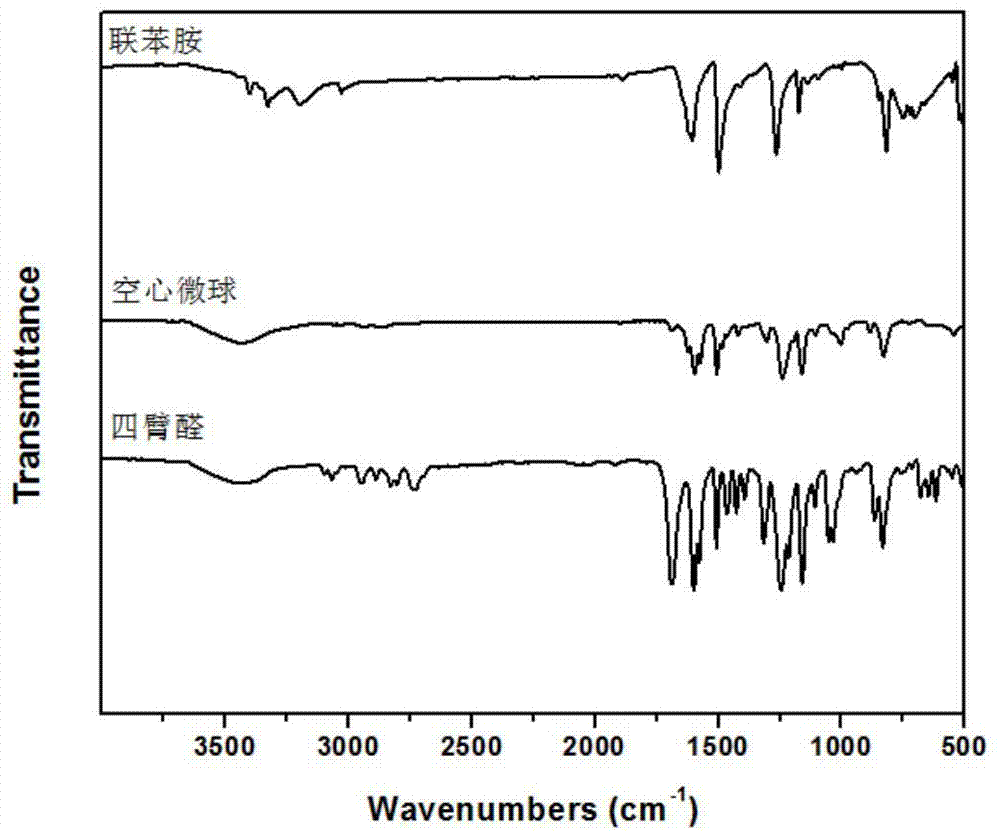

[0020] Add 0.111g (0.2mmol) of four-arm aldehyde and 0.074g (0.4mmol) benzidine to 10mL of 1,2-dichloroethane to prepare a homogeneous solution, and add 0.4mL of 3M acetic acid solution to the solution , evenly dispersed, sealed and placed in an oven at 85°C, kept for 72h, cooled, filtered and washed repeatedly with chloroform, dried at 120°C for 24h to obtain the covalent organic framework hollow microsphere polymer SBQB, its scanning electron microscope and Transmission electron microscope picture as figure 1 , figure 2 shown. Depend on figure 1 It can be seen that the diameter of the hollow spheres is 3-5 μm, most of the spheres are piled together, no monodisperse microspheres appear, and the surface of the microspheres is very short burrs similar to sea urchins. Depend on figure 2 It can be seen that there are still some holes on the surface of the prepared hollow spheres, and the size of the holes is 100-400nm. The infrared characterization figure ( i...

Embodiment 2

[0022]

[0023] Add 0.111g (0.2mmol) of four-arm aldehyde and 0.104g (0.4mmol) of 4,4'-diaminoterphenyl to 10mL of 1,2-dichloroethane to prepare a homogeneous solution, add 0.4mL of 3M acetic acid solution, evenly dispersed, sealed and placed in an oven at 65°C, kept for 48h, cooled, filtered and washed repeatedly with chloroform, dried at 120°C for 24h to obtain the covalent organic framework hollow microsphere polymer SBQBI.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com