A method for preparing high-purity magnesium oxide from old brine

A magnesium oxide, high-purity technology, applied in the direction of magnesium oxide, chloride preparation, chlorine/hydrogen chloride, etc., can solve the problems that affect the purity of magnesium oxide products, there is no impurity removal step in the mother liquor, and there is no magnesium chloride solution, etc., so as to achieve easy operation and control , The process is simple and mature, and the effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

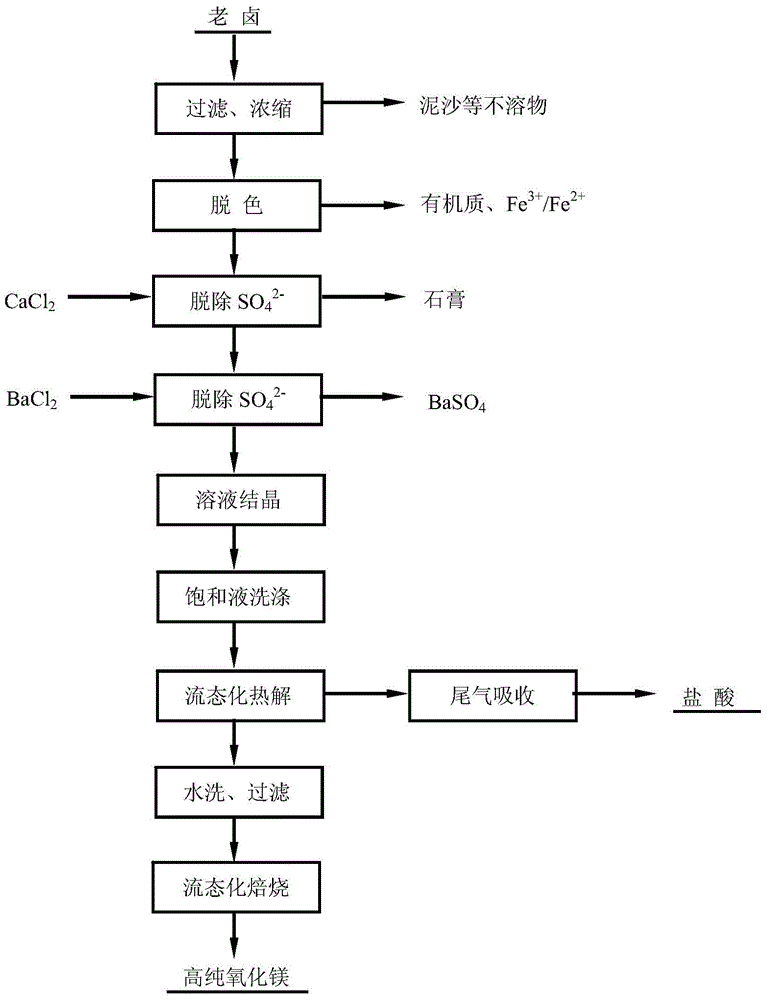

Method used

Image

Examples

Embodiment 1

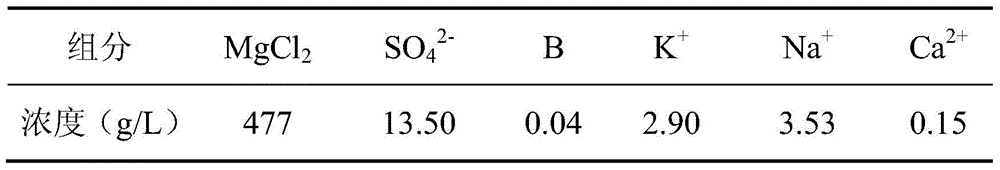

[0047] The main composition of the raw material old brine is shown in Table 1.

[0048] Table 1

[0049]

[0050] First, take 2000ml of the above-mentioned old brine, vacuum filter out solid insoluble substances such as silt, and concentrate to saturation to obtain a dark yellow-brown saturated liquid. Next, at 40° C., add 2 kg of gac to the above saturated solution, stir from time to time, filter after 3 hours, the dark yellow-brown saturated solution becomes a colorless clear solution, and the solution volume is 1360 ml. Add 17.7g of anhydrous calcium chloride to the colorless and clear solution, stir and react at 80°C for 20 minutes, filter to obtain high-purity gypsum, and use the filtrate for later use. Add 6.8g of dry barium chloride powder to the filtrate, stir and react for 20min at 80°C, and filter to obtain complete removal of SO 4 2- The colorless and clear filtrate. Take 1000ml of colorless and clear filtrate, heat to evaporate 120ml of water, then naturally...

Embodiment 2

[0054] Take 2000ml of the above-mentioned old brine, vacuum filter out solid insoluble substances such as silt, and concentrate to saturation to obtain a dark yellow-brown saturated liquid. Next, at 20°C, add 2 kg of activated carbon to the above saturated solution, stir it from time to time, filter after 3 hours, the dark yellow-brown saturated solution becomes a colorless clear solution, and the volume of the solution is about 1350 ml. Add 17.7g of anhydrous calcium chloride to the colorless and clear solution, stir and react at 80°C for 20 minutes, filter to obtain high-purity gypsum, and use the filtrate for later use. Add 6.8g of dry barium chloride powder to the filtrate, stir and react for 20min at 80°C, and filter to obtain complete removal of SO 4 2- The colorless and clear filtrate. Take 1000ml of colorless and clear filtrate, heat to evaporate 150ml of water, then naturally cool to room temperature, the solution spontaneously crystallizes, and then filters to obta...

Embodiment 3

[0059] Take 2000ml of the above-mentioned old brine, vacuum filter out solid insoluble substances such as silt, and concentrate to saturation to obtain a dark yellow-brown saturated liquid. Next, at 50° C., add 2 kg of crushed coke to the above saturated solution, stir occasionally, and filter after 3 hours. The dark yellow-brown saturated solution becomes a colorless and clear solution, and the volume of the solution is about 1360 ml. Add 17.7g of anhydrous calcium chloride to the colorless and clear solution, stir and react at 60°C for 20 minutes, filter to obtain high-purity gypsum, and use the filtrate for later use. Add 6.8g of dry barium chloride powder to the filtrate, stir and react for 20min at 60°C, and filter to obtain complete removal of SO 4 2- The colorless and clear filtrate. Take 1000ml of colorless and clear filtrate, heat to evaporate 120ml of water, then naturally cool to room temperature, the solution spontaneously crystallizes, and then filters to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com