Polyacrylate emulsion microgel and preparation method thereof

A technology of polyacrylate emulsion and n-butyl acrylate, which is applied in the field of polyacrylate emulsion microgel and its preparation, can solve the problems of non-presentation of gel rate and increase of graft rate, and achieve enhanced water resistance and film formation dense effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

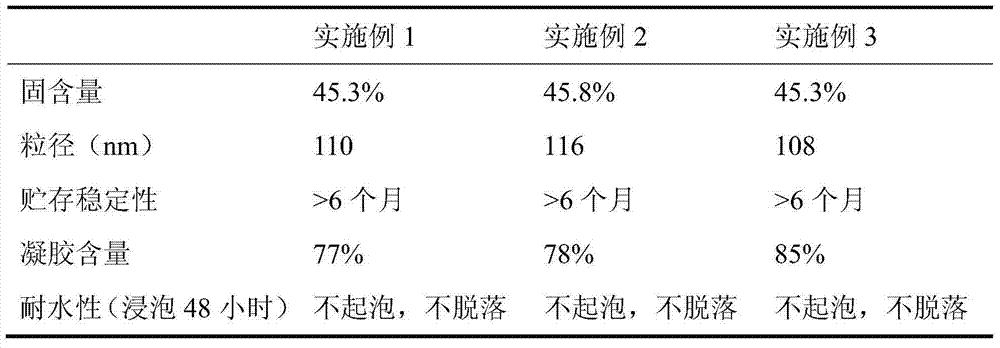

Examples

Embodiment 1

[0034] (1) 2.2g PS-725A (Shanghai Zhongcheng Fine Chemical Co., Ltd.), 1.8g LE407k (SASOL company), 0.1g sodium bicarbonate (Shanghai Aibi Chemical Reagent Co., Ltd.), 5g n-butyl acrylate (Guangzhou Zhongye Chemical Co., Ltd.) monomers were added to 96g deionized water, stirred at 300rpm and started Heat up; when the temperature rises to 85°C, adjust the stirring to 150rpm, add 4.3g of sodium persulfate (Suzhou Huahang Chemical Technology Co., Ltd.) aqueous solution (0.3g of sodium persulfate dissolved in 4g of deionized water);

[0035] (2) After the obvious blue light appeared in the reaction system, 58g of n-butyl acrylate (Guangzhou Zhongye Chemical Co., Ltd.) monomer was added dropwise within 7 hours, and 5g of n-butyl acrylate (Guangzhou Zhongye Chemical Co., Ltd. City Zhongye Chemical Co., Ltd.) monomer and the mixed solution of 32g methyl methacrylate (Guangzhou Zhongye Chemical Co., Ltd.) monomer, and, when starting to drop monomer, drip 13.7g sodium persulfate ( Su...

Embodiment 2

[0038] (1) 2g PS-725A (Shanghai Zhongcheng Fine Chemical Co., Ltd.), 1.8g LE407k (SASOL company), 0.12g sodium bicarbonate (Shanghai Aibi Chemical Reagent Co., Ltd.), 5g n-butyl acrylate (Guangzhou Zhongye Chemical Co., Ltd.) monomers were added to 95.34g deionized water, stirred at 700rpm and Start to heat up; when the temperature rises to 82°C, adjust the stirring to 200rpm, add 4.3g of sodium persulfate (Suzhou Huahang Chemical Technology Co., Ltd.) aqueous solution (0.3g of sodium persulfate is dissolved in 4g of deionized water);

[0039] (2) After the obvious blue light appeared in the reaction system, 60g of n-butyl acrylate (Guangzhou Zhongye Chemical Co., Ltd.) monomer was added dropwise within 6 hours, and then 5g of n-butyl acrylate (Guangzhou Zhongye Chemical Co., Ltd. City Zhongye Chemical Co., Ltd.) monomer and the mixed solution of 30g methyl methacrylate (Guangzhou Zhongye Chemical Co., Ltd.) monomer, and, when starting to drop monomer, drip 14.5g sodium persu...

Embodiment 3

[0042] (1) 2.4g PS-725A (Shanghai Zhongcheng Fine Chemical Co., Ltd.), 1.6g LE407k (SASOL company), 0.2g sodium bicarbonate (Shanghai Aibi Chemical Reagent Co., Ltd.), 5g n-butyl acrylate (Guangzhou Zhongye Chemical Co., Ltd.) monomers were added to 94.1g deionized water, stirred under the condition of 550rpm and Start to heat up; when the temperature rises to 83°C, adjust the stirring to 250rpm, add 4.3g of sodium persulfate (Suzhou Huahang Chemical Technology Co., Ltd.) aqueous solution (0.3g of sodium persulfate is dissolved in 4g of deionized water);

[0043] (2) After the system has obvious blue light, add 62g of n-butyl acrylate (Guangzhou Zhongye Chemical Co., Ltd.) dropwise within 5 hours, and then add 5g of n-butyl acrylate (Guangzhou Zhongye Chemical Co., Ltd. Zhongye Chemical Co., Ltd.) monomer and 28g methyl methacrylate (Guangzhou Zhongye Chemical Co., Ltd.) Huahang Chemical Technology Co., Ltd.) aqueous solution (3g sodium persulfate is dissolved in 12.5g deion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com