An enzyme-free ECL glucose sensor

A technology of glucose sensor and g-c3n4, which is applied in the field of enzyme-free ECL glucose sensor to achieve the effect of high selectivity, weakened hindering effect and sensitive detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

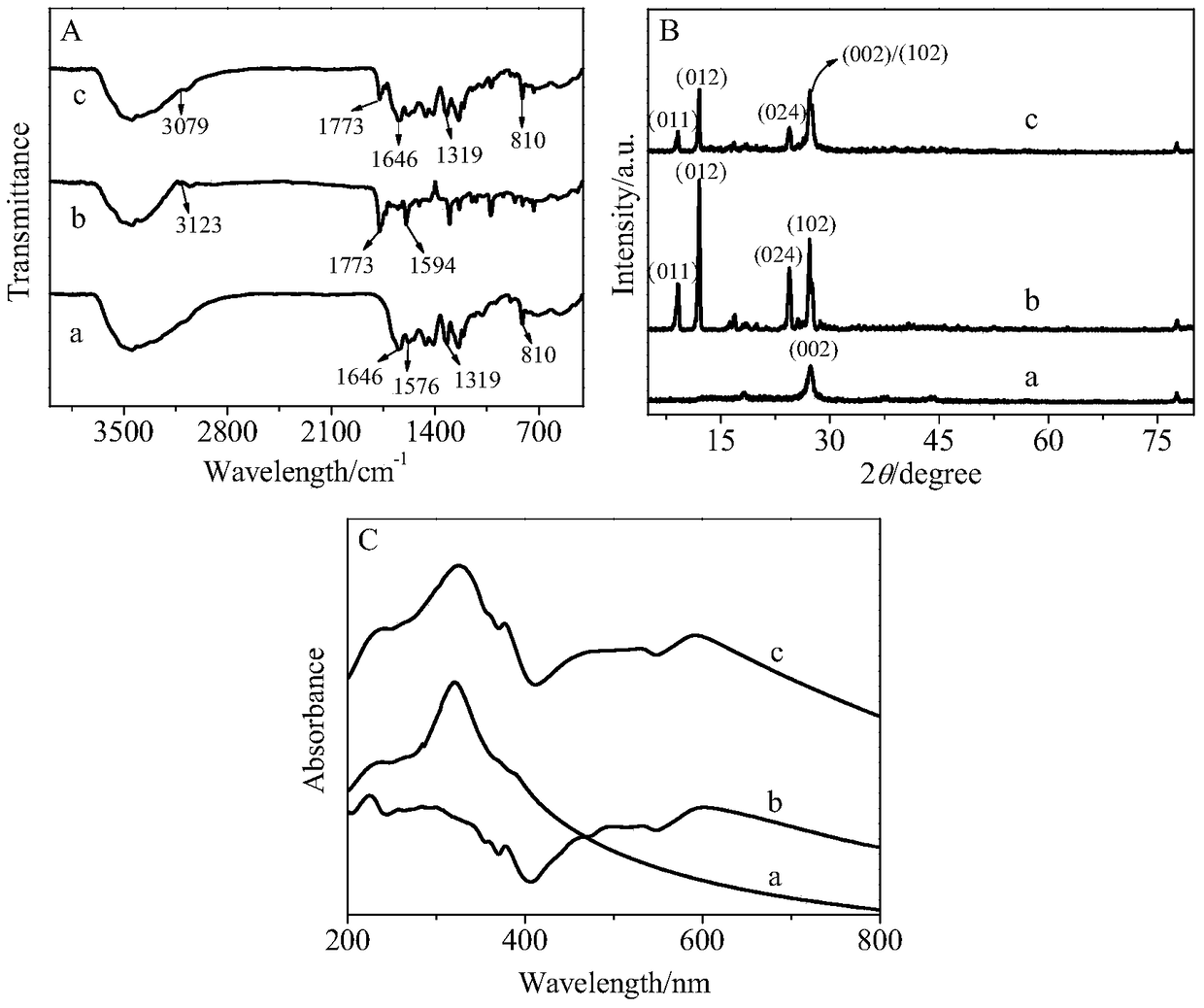

[0061] 1. Preparation of g-C 3 N 4 Nanosheets

[0062] Take 20g of melamine powder in a ceramic crucible, cover it, heat up to 600°C at a heating rate of 3°C / min, calcinate for 2 hours, and cool naturally to room temperature to obtain a yellow block g-C 3 N 4 powder. Take 250mg block g-C 3 N 4 The powder was dispersed in 250mL water and ultrasonicated for 10h. Centrifuge the obtained suspension at a rate of 5000rpm for 5min to remove the unpeeled chunks of g-C 3 N 4 powder. The supernatant was dried to obtain g-C 3 N 4 Nanosheets.

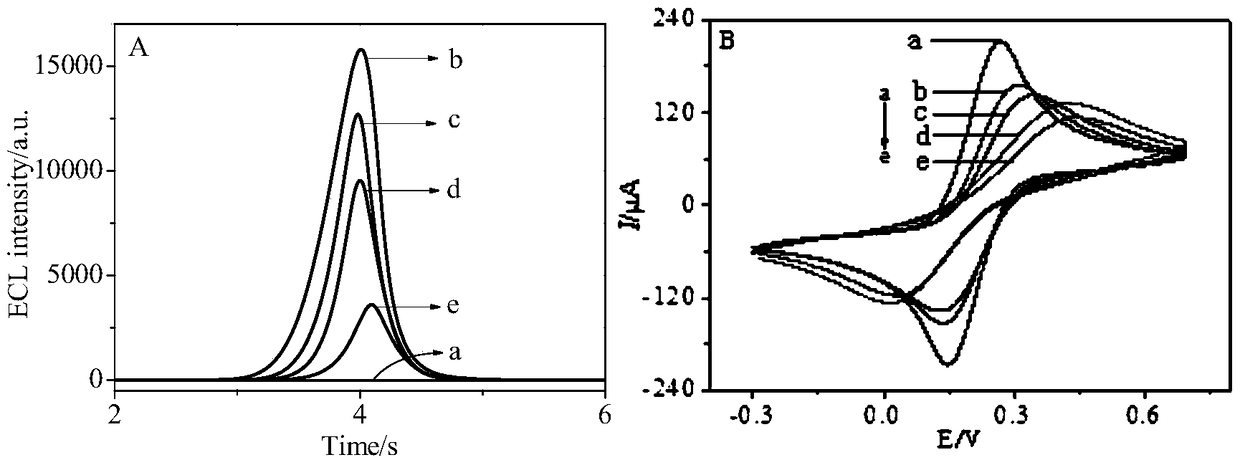

[0063] 2. Preparation of sensors

[0064] Glassy carbon electrodes (GCE, Φ=4mm) were respectively treated with 0.3 and 0.05 μm Al 2 o 3 After powder polishing, it was cleaned ultrasonically in distilled water, ethanol and double distilled water, and left to dry at room temperature. 1mg g-C 3 N 4 Nanosheets and 1mg PTCA were dispersed in 2mL water and sonicated for 8 hours to obtain pink g-C 3 N 4 - Dispersions of PTCA nanocomposi...

Embodiment 2

[0106] 1. Preparation of g-C 3 N 4 Nanosheets

[0107] Take 20g of melamine powder in a ceramic crucible, cover it, heat up to 595°C at a heating rate of 2.5°C / min, calcinate for 2.5h, and cool naturally to room temperature to form a yellow block g-C 3 N 4 powder. Take 250mg block g-C 3 N 4 The powder was dispersed in 250mL water and ultrasonicated for 9.5h. Centrifuge the obtained suspension at a rate of 4900rpm for 8min to remove the unpeeled chunks of g-C 3 N 4 powder. The supernatant was dried to obtain g-C3 N 4 Nanosheets.

[0108] 2. Preparation of sensors

[0109] Glassy carbon electrodes (GCE, Φ=4mm) were respectively treated with 0.3 and 0.05 μm Al 2 o 3 After powder polishing, it was cleaned ultrasonically in distilled water, ethanol and double distilled water, and left to dry at room temperature. 1mg g-C 3 N 4 Nanosheets and 0.9mg PTCA were dispersed in 1.995mL water, sonicated for 7 hours to obtain pink g-C 3 N 4 - Dispersions of PTCA nanocomposit...

Embodiment 3

[0119] 1. Preparation of g-C 3 N 4 Nanosheets

[0120] Take 20g of melamine powder in a ceramic crucible, cover it, heat up to 605°C at a heating rate of 3.5°C / min, calcinate for 1.5h, and cool naturally to room temperature to form a yellow block g-C 3 N 4 powder. Take 250mg block g-C 3 N 4 The powder was dispersed in 250mL water and ultrasonicated for 10.5h. Centrifuge the obtained suspension at a rate of 5200rpm for 4min to remove the lumps of g-C that have not yet peeled off 3 N 4 powder. The supernatant was dried to obtain g-C 3 N 4 Nanosheets.

[0121] 2. Preparation of sensors

[0122] Glassy carbon electrodes (GCE, Φ=4mm) were respectively treated with 0.3 and 0.05 μm Al 2 o 3 After powder polishing, it was cleaned ultrasonically in distilled water, ethanol and double distilled water, and left to dry at room temperature. 1mg g-C 3 N 4 Nanosheets and 1.1mg PTCA were dispersed in 1.995mL water, sonicated for 9h to obtain pink g-C 3 N 4 - Dispersions of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com