Production method for semiconductor epitaxial wafer, semiconductor epitaxial wafer, and production method for solid-state imaging element

A technology for epitaxial wafers and manufacturing methods, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve problems such as insufficiency, achieve high gettering ability, and inhibit metal pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

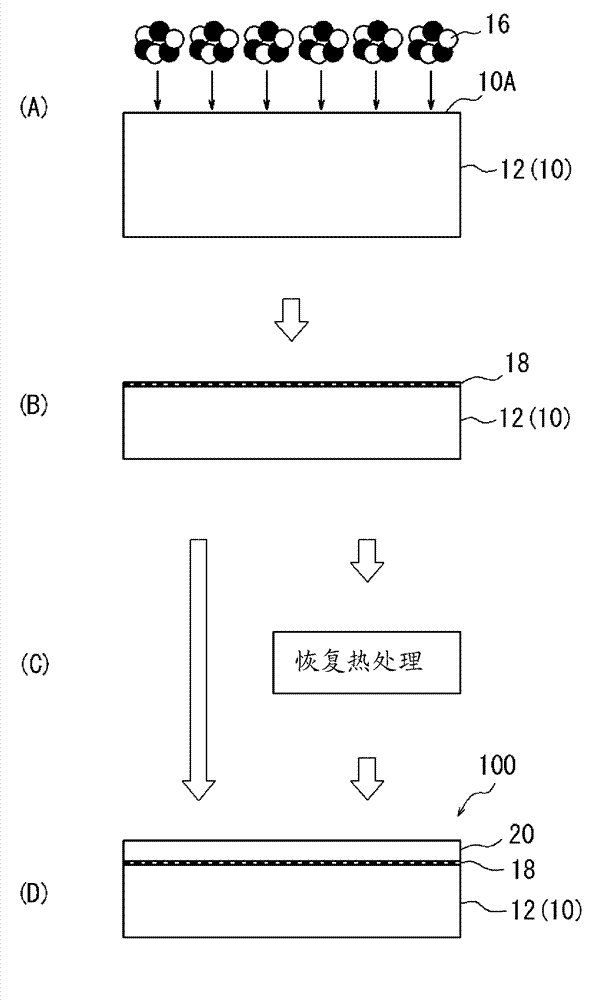

[0086] (Refer to the experimental example)

[0087] First, in order to clarify the difference between cluster ion irradiation and monomer ion implantation, the following experiments were performed.

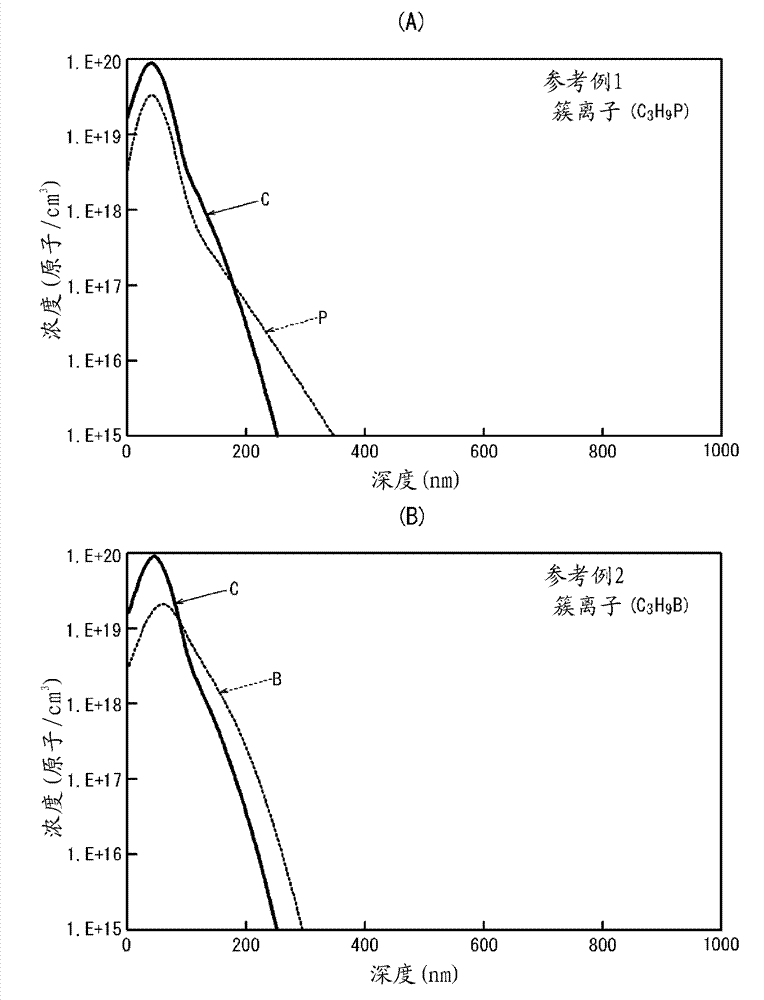

reference example 1)

[0089] An n-type silicon wafer (diameter: 300 mm, thickness: 725 μm, doping: phosphorus, doping concentration: 5×10 14 atom / cm 3 ). Next, trimethylphosphine (C 3 h 9 P) ionization, at a carbon dose of 5.0 x 10 14 atom / cm 2 , Phosphorus dosage 1.7×10 14 atom / cm 2 The silicon wafer was irradiated under the conditions of an accelerating voltage of 12.8 keV / atom per carbon atom and an accelerating voltage of 32 keV / atom per phosphorus atom.

reference example 2)

[0091] For the same silicon wafer as in Reference Example 1, instead of trimethylphosphine, trimethylboron (C 3 h 9 B) As the material gas, cluster ions are generated, and the dose of boron is 1.7×10 14 atom / cm 2 The silicon wafer was irradiated under the same conditions as in Reference Example 1 except that the accelerating voltage per boron atom was 14.5 keV / atom.

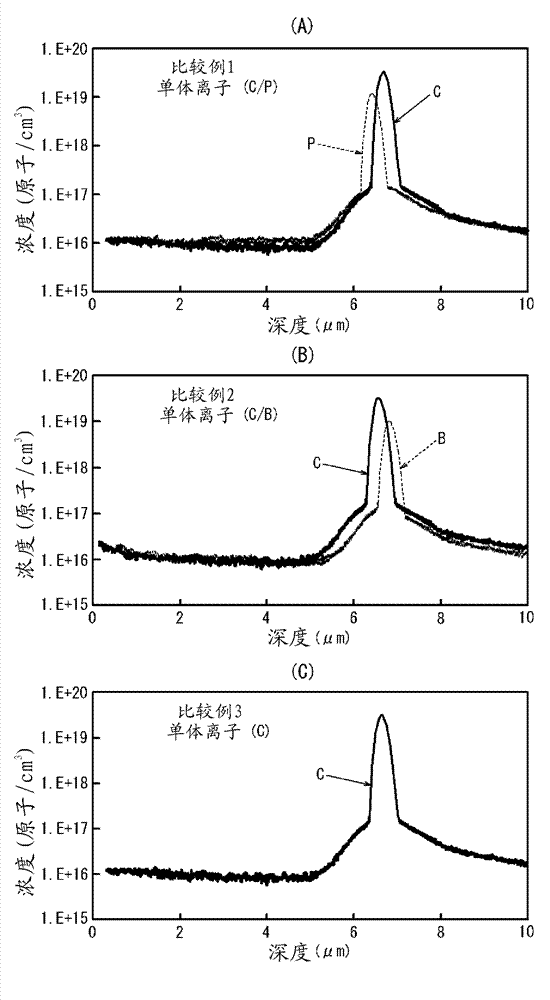

[0092] (reference example 3)

[0093] For the same silicon wafer as in Reference Example 1, instead of cluster ion irradiation, CO 2 As a material gas, carbon monomer ions are generated at a dose of 5.0×10 14 atom / cm 2 1. Under the condition of accelerating voltage 80keV / atom, the silicon wafer is implanted. Afterwards, phosphine trihydrogen (PH 3 ) as a material gas to generate phosphorous monomer ions at a dose of 1.7×10 14 atom / cm 2 1. Under the condition of accelerating voltage 80keV / atom, the silicon wafer is implanted.

[0094] (reference example 4)

[0095] For the same silicon wafer as in Refer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com