A large-size hydrophilic organic polymer liquid phase monolithic chromatographic column and its preparation and application

A monolithic chromatographic column and hydrophilic organic technology, which is applied in the field of large-size hydrophilic organic polymer liquid-phase monolithic chromatographic column and its preparation and application, and can solve problems that affect the research and application of large-sized monolithic chromatographic columns, unsatisfactory separation effects, and overall Low column efficiency and other issues, to achieve excellent separation ability and separation efficiency, low cost, not easy to break and collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

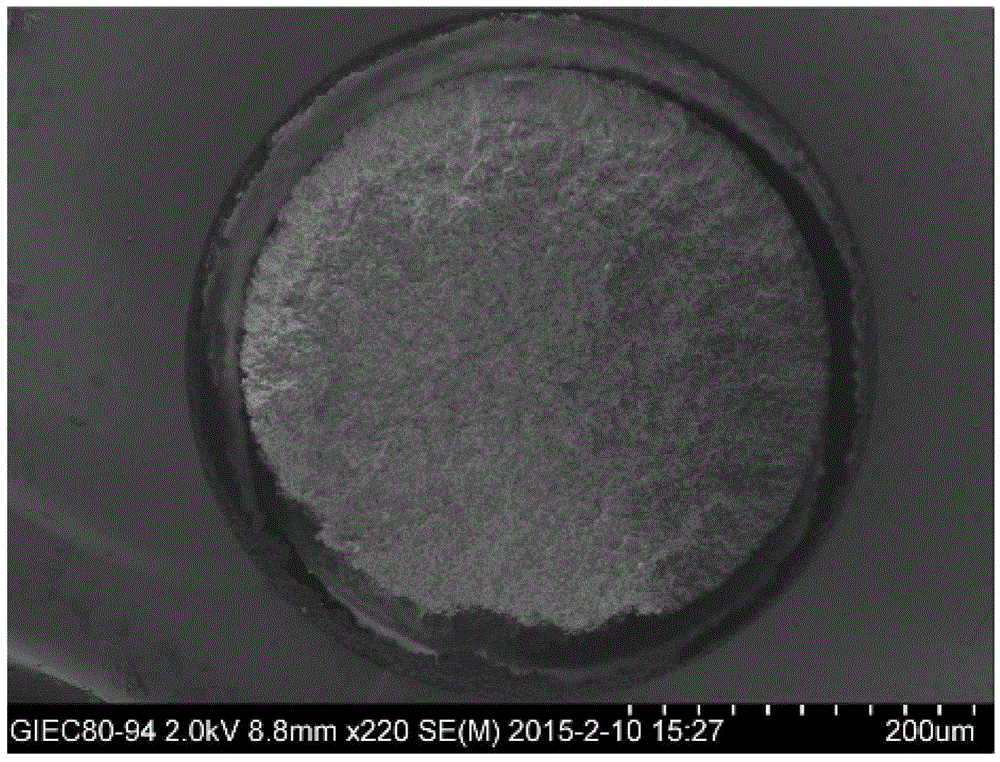

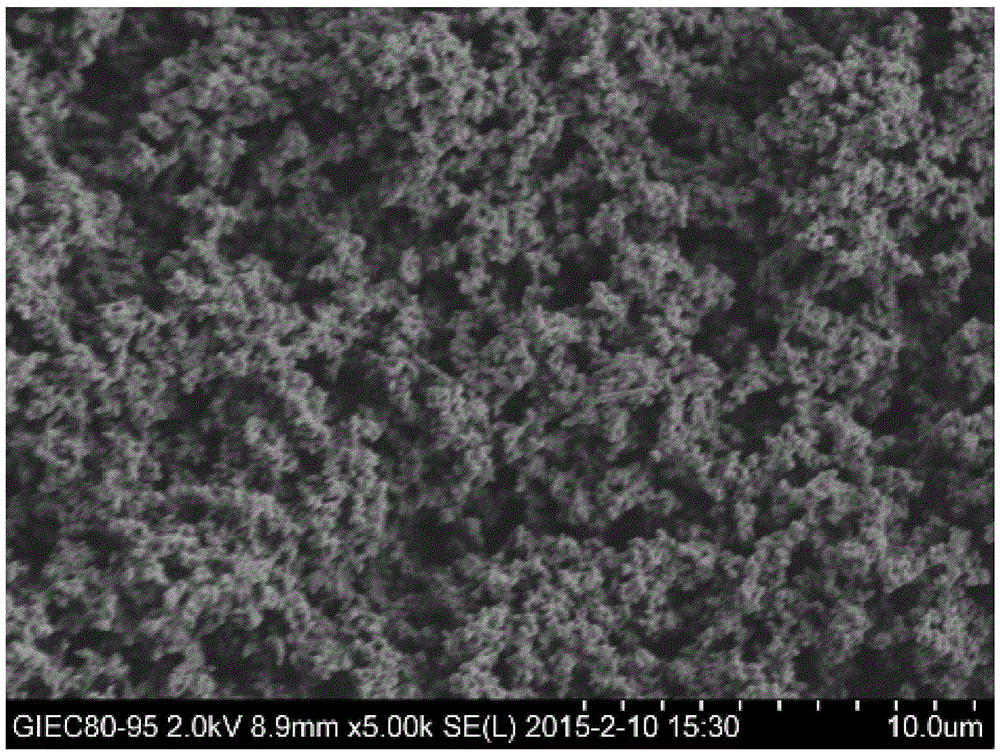

[0035] Monomer 3-[N,N-dimethyl-[2-(2-methylprop-2-enoyloxy)aminopropyl]ammonium]propane-1-sulfonic acid inner salt 0.0870g, The joint agent N, N-methylenebisacrylamide 0.0132g, the porogen methanol 0.2100g and the initiator azobisisobutyronitrile 0.0020g are prepared into a reaction mixture, which is ultrasonically degassed for 5 minutes and poured into the pretreated Then, seal both ends of the quartz capillary and put it in a 60°C water bath for 12 hours; after the reaction, connect the quartz capillary to a high-pressure pump, wash away impurities and unreacted substances, and obtain a large-sized SPP-co-MBA (400 micron internal diameter) hydrophilic organic polymer liquid monolithic chromatographic column, the electron scanning electron microscope result of organic polymer in the column is as follows figure 1 and figure 2 shown.

Embodiment 2

[0037] Monomer 3-[N,N-dimethyl-[2-(2-methylprop-2-enoyloxy)aminopropyl]ammonium]propane-1-sulfonic acid inner salt 0.0851g, The coupling agent N, N-methylenebisacrylamide 0.0150g, the porogen methanol 0.2089g and the initiator azobisisobutyronitrile 0.0033g are prepared into a reaction mixture, and after ultrasonic degassing, it is poured into pretreated quartz In the capillary, then seal both ends of the quartz capillary and put it in a 60°C water bath to react for 12 hours. After the reaction is completed, connect the quartz capillary to a high-pressure pump, rinse to remove unreacted substances, and obtain a large-sized SPP-co-MBA (400 micron inner diameter ) Hydrophilic organic polymer liquid phase monolithic chromatographic column.

Embodiment 3

[0039] Monomer 3-[N,N-dimethyl-[2-(2-methylprop-2-enoyloxy)aminopropyl]ammonium]propane-1-sulfonic acid inner salt 0.0900g, The coupling agent N, N-methylenebisacrylamide 0.0104g, the porogen methanol 0.2119g and the initiator azobisisobutyronitrile 0.0035g are prepared into a reaction mixture, and after ultrasonic degassing, pour it into a pretreated quartz capillary Then seal both ends of the quartz capillary and put it in a 60°C water bath to react for 12 hours. After the reaction is completed, connect the quartz capillary to a high-pressure pump, rinse to remove unreacted substances, and obtain a large-sized SPP-co-MBA (400 micron inner diameter) Hydrophilic organic polymer liquid phase monolithic column.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com