Production method of multielement microelement amino acid chelating fertilizer

A technology of trace elements and production methods, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of soil environmental pollution, lack of fertilizer efficiency, low chelation efficiency, etc., to reduce pollution, easily biodegradable, and chelating powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

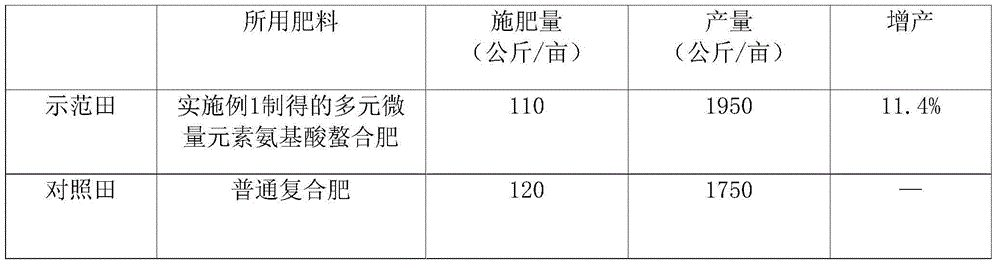

Embodiment 1

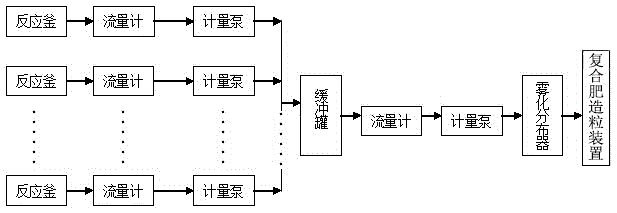

[0025] Such as figure 1 Shown, a kind of production method of multivariate trace element amino acid chelate fertilizer comprises the following steps:

[0026] (1) For the trace elements iron, manganese, zinc, and copper, in different reaction kettles, add the process water and the sulfate of the trace elements in proportion, slowly add the corresponding amount of sodium polyaspartate, and dissolve completely Finally, use dilute sulfuric acid and ammonia water to adjust to the desired pH value, raise the temperature to 70°C, and react for 1 hour at a speed of 500r / min to obtain polyaspartic acid chelated ferrous, polyaspartic acid chelated manganese, Polyaspartic acid chelated zinc, polyaspartic acid chelated copper, wherein the sulfate that iron adopts is ferrous sulfate heptahydrate, and the mass ratio of polyaspartic acid sodium, process water, ferrous sulfate heptahydrate is 1:1.5:2.05, pH=4.5 required for reaction; The sulfate salt that manganese adopts is manganese sulfa...

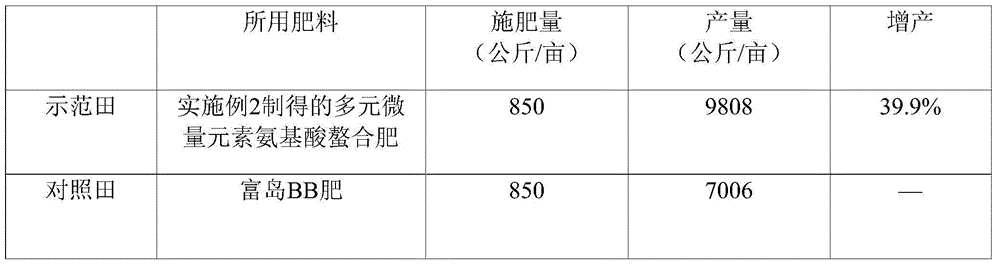

Embodiment 2

[0041] Such as figure 1 Shown, a kind of production method of multivariate trace element amino acid chelate fertilizer comprises the following steps:

[0042] (1) For trace elements manganese, zinc, copper, respectively in different reactors, add process water and the sulfate of this trace element in proportion, slowly add the corresponding amount of sodium polyaspartate, after dissolving completely, Use dilute sulfuric acid and ammonia water to adjust to the desired pH value, raise the temperature to 70°C, and react for 1 hour at a speed of 500r / min to prepare polyaspartic acid chelated manganese, polyaspartic acid chelated zinc, and polyaspartic acid Amino acid chelated copper, wherein the sulfate used for manganese is manganese sulfate monohydrate, the mass ratio of sodium polyaspartate, process water, and manganese sulfate monohydrate is 1:2:1.2, and the required pH=5.5 for the reaction; The sulfate that adopts is zinc sulfate heptahydrate respectively, and the mass ratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com