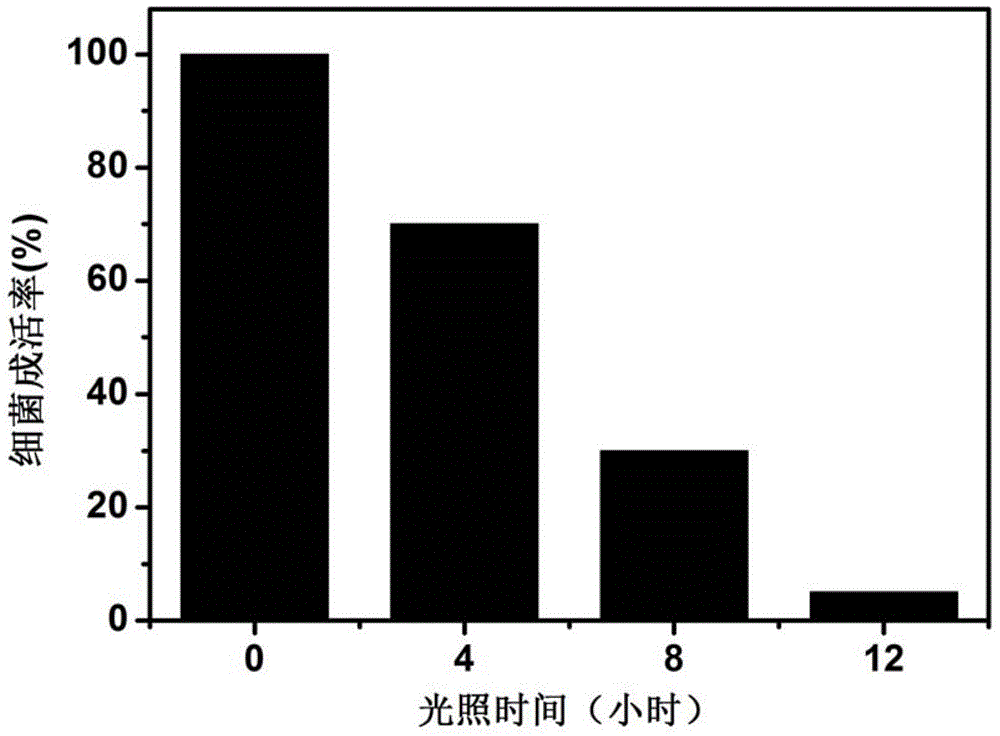

Carbon quantum dot visible light photocatalyst coating and preparation method thereof

A technology of carbon quantum dots and visible light, which is applied in the field of carbon quantum dot visible light photocatalyst coatings and its preparation, can solve the problems of easy aggregation of nanoparticles, uneven spraying, and affecting the performance of photocatalysts, and achieve good film-forming properties and improved storage stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

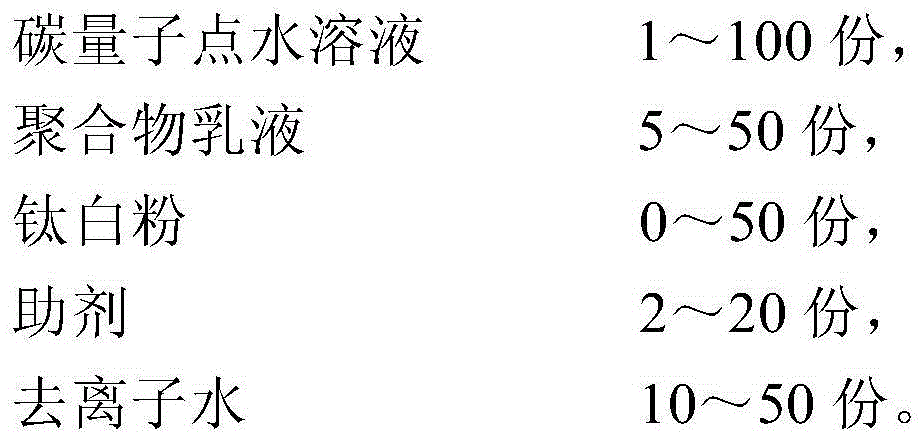

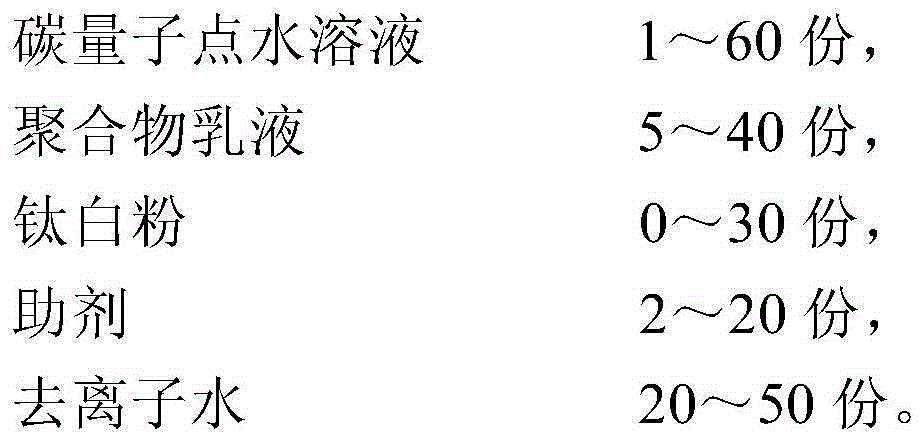

[0034] A kind of carbon quantum dot visible light photocatalyst coating, comprises the raw material of following parts by weight: the aqueous solution 100g (the mass percent that carbon quantum dot accounts for in the carbon quantum dot aqueous solution is 0.5%) of the carbon quantum dot containing heteroatom O doping, benzene Acrylic emulsion 30g, titanium dioxide 5g, dispersant 3g, film forming agent 1g, defoamer 0.5g, wetting agent 0.8g, deionized water 30g. The preparation method of this coating is as follows:

[0035] Accurately weigh deionized water and various additives such as dispersant, defoamer, wetting agent, film-forming agent, etc., add the total weight of deionized water and 5% of the total weight of additives into the stirring device, and then add The titanium dioxide in all parts by weight is stirred for 0.5 hours, and the titanium dioxide slurry is ground by a sander until the fineness reaches 60-12 mesh, then the whole weight of styrene-acrylic emulsion is a...

Embodiment 2

[0037] A kind of carbon quantum dot visible light photocatalyst coating, comprises the raw material of following parts by weight: the aqueous solution 80g (the mass percent that carbon quantum dot accounts for in the carbon quantum dot aqueous solution is 0.1%) of the carbon quantum dot containing heteroatom Se doping, poly Acrylic emulsion 40g, titanium dioxide 2g, dispersant 2g, film forming agent 0.5g, defoamer 0.3g, wetting agent 1g, deionized water 50g. The preparation method of this coating is as follows:

[0038] Accurately weigh deionized water and various additives such as dispersant, defoamer, wetting agent, film-forming agent, etc., add the total weight of deionized water and 5% of the total weight of additives into the stirring device, and then add The whole weight of titanium dioxide is stirred for 1 hour, and the titanium dioxide slurry is ground to a fineness of 100 mesh by a sander, then the whole weight of polyacrylic acid emulsion is added, and the remaining ...

Embodiment 3

[0045] A kind of carbon quantum dot visible light photocatalyst coating, comprises the raw material of following parts by weight: the aqueous solution 50g (the mass percent that carbon quantum dot accounts for in the carbon quantum dot aqueous solution is 0.2%) of the carbon quantum dot containing heteroatom P doping, silicon Acrylic emulsion 50g, titanium dioxide 50g, dispersant 5g, film forming agent 5g, defoamer 1g, wetting agent 2g, antifungal agent 1g, deionized water 40g. The preparation method of this coating is as follows:

[0046] Accurately weigh deionized water and various additives such as dispersant, defoamer, wetting agent, film-forming agent, antifungal agent, etc., and add all weight of deionized water and 5% of all additives to the stirring device Add the titanium dioxide in all parts by weight, stir for 0.8 hours, grind the titanium dioxide slurry with a sander until the fineness reaches 100 mesh, then add the whole weight of styrene-acrylic emulsion, add the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com