Extra virgin camellia oil and preparation method thereof

A kind of camellia oil, super-grade technology, applied in the direction of fat oil/fat refining, edible oil/fat, fat oil/fat production, etc., can solve the problems of complicated process, long crystallization time, low production efficiency, etc., and meet the requirements of low equipment conditions and process Simple, Appetite-Enhancing Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

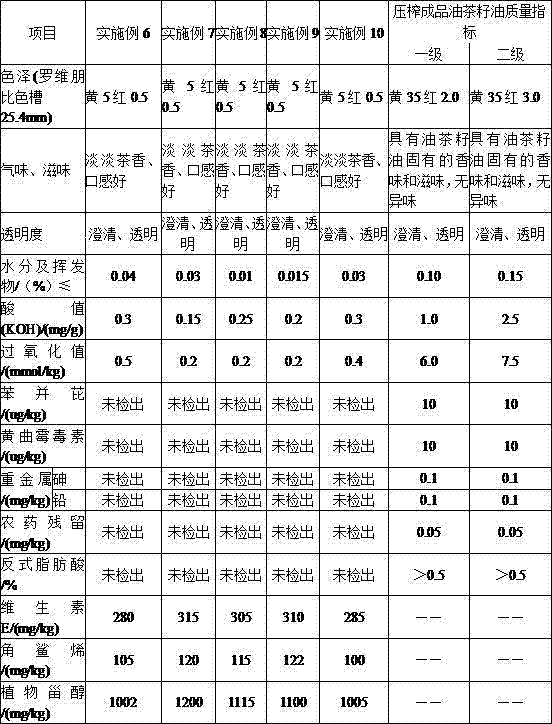

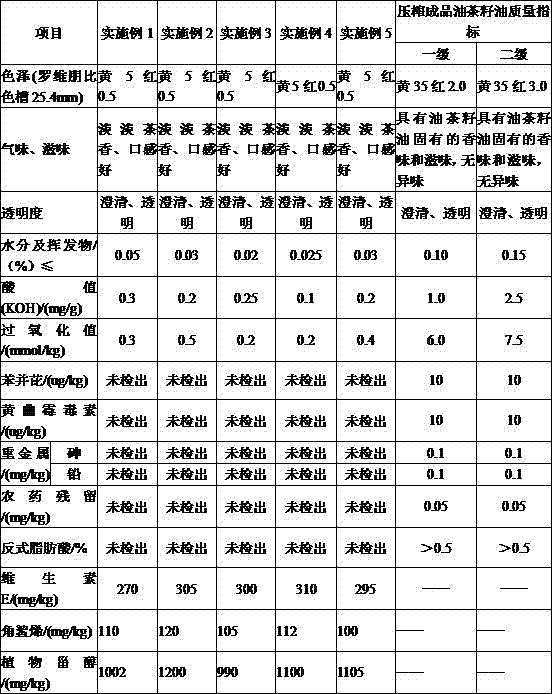

Examples

Embodiment 1

[0040] Adopt following method, prepared a kind of camellia oil:

[0041] A. Preparation of extra virgin camellia oil raw material: get the fresh tea seeds of that year and spread them out to dry naturally; make the moisture control at 8% by mass; remove all the shells of the camellia seeds to obtain the camellia seed kernels;

[0042] B. Virgin pressing: Put the Camellia oleifera seeds obtained in step A into an oil press to press, the temperature of the seeds entering is the ambient temperature, i.e. the air temperature, and the temperature of the pressing chamber and the squeezed oil is controlled to be lower than 60°C to obtain virgin camellia oil and tea dry;

[0043] C. Freezing and removing impurities: put the virgin camellia oil into a freezing tank, freeze and cool down according to the following three-stage procedure, and carry out crystal growth and remove impurities. The first stage: first cool down to 20°C at a rate of 2.0°C / hour, keep it for 15 hours, and the sti...

Embodiment 2

[0047] A kind of extra virgin camellia oil was prepared in the same way as in Example 1. The difference was that before the program freezing and cooling in step C, the crude camellia oil obtained in step B was added to the crude product of the virgin camellia oil. The 60-mesh fine powder is ground, and the mass ratio of the added amount of the chaku fine powder to the crude product of the virgin camellia oil is 2:100, which acts as a crystal nucleus during the freeze crystallization process and improves the purification effect of the freeze crystallization.

Embodiment 3

[0049] A kind of extra virgin camellia oil was prepared by the method basically the same as that in Example 1, the difference being that before the program freezing and cooling in step C, the tea obtained in step B was added to the crude product of the virgin camellia oil respectively. The 200-mesh fine powder ground into dry tea, the mass ratio of the added amount of the tea dry fine powder to the crude product of the virgin camellia oil is 0.05:100, acts as a crystal nucleus during the freeze crystallization process, and improves the purification effect of freeze crystallization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com