Preparation method of modified montmorillonite powder for feeds

A technology of montmorillonite powder and montmorillonite, which is applied in the field of montmorillonite modified powder preparation, can solve the problems of dehydration and separation of modified products, low ratio of quaternary ammonium compound montmorillonite, and high drying energy consumption, and achieves Reasonable selection of material properties, good practical application value, and low drying energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

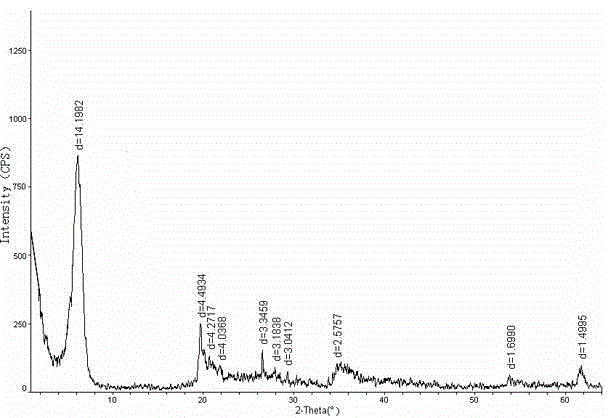

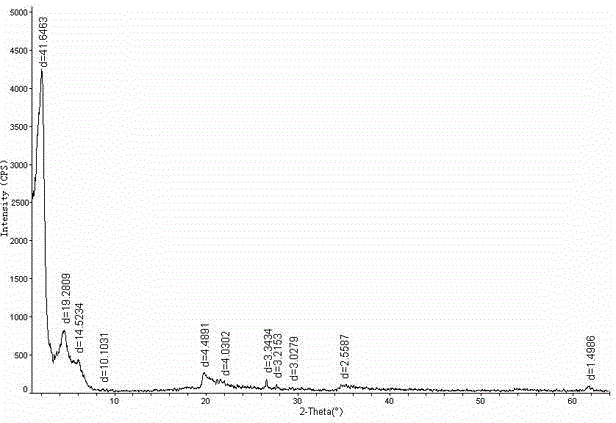

Embodiment 1

[0024] A preparation method of modified montmorillonite powder for feed, which is to first prepare 100 g of calcium-based montmorillonite powder with montmorillonite content ≥ 80%, total cation exchange (CEC) of 1.0 mmol / g montmorillonite powder, and d001 value of 1.42 nm. Add the destoned powder into the electric heating oil bath high-speed mixing mixer, stir and heat to 85°C, then add 0.7mmol of solid dioctadecyldimethylammonium chloride per g of montmorillonite, and heat at 1000r / min Mix and stir at high speed for 30 minutes, and dry at 105°C to remove excess water and dispersant brought in by quaternary ammonium salts. The montmorillonite was further dispersed to obtain a 325-mesh modified montmorillonite powder with a d001 value of 4.16nm and a loss-on-ignition rate of 35.3% at 850°C as measured by the X-ray diffraction method. The X-ray diffraction pattern of the finished product is shown in the attached figure 2 , with figure 1 It is the X-ray diffraction pattern of ...

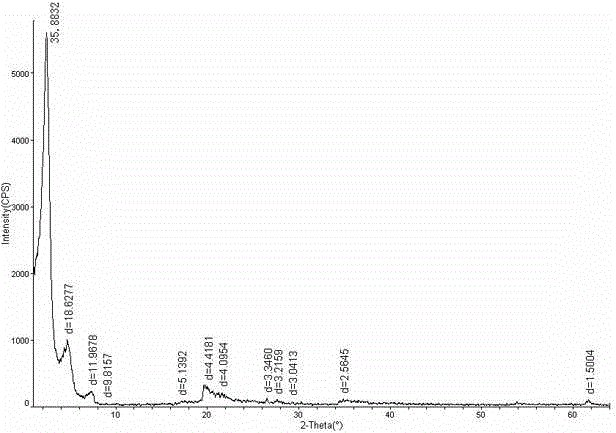

Embodiment 2

[0026] A preparation method of modified montmorillonite powder for feed, which is to first prepare 100 g of calcium-based montmorillonite powder with montmorillonite content ≥ 80%, total cation exchange (CEC) of 1.0 mmol / g montmorillonite powder, and d001 value of 1.42 nm. Add the destoned powder into the electric heating oil bath high-speed mixing mixer, stir and heat to 85°C, then add 0.7mmol of solid octadecyltrimethylammonium chloride per g of montmorillonite, and mix at a high speed of 1000r / min under heat preservation Stir and modify for 30 minutes, dry at 105°C to remove excess water and dispersant brought in by quaternary ammonium salts, the drying time is controlled according to the volatile content of the dried material at 105°C ≤ 5%, the modified montmorillonite after drying Further break up and disperse to obtain 325-mesh modified montmorillonite powder with a d001 value of 3.59nm and a loss-on-ignition rate of 24.2% at 850°C as measured by the X-ray diffraction met...

Embodiment 3

[0028] A preparation method of modified montmorillonite powder for feed, which is to first prepare 100 g of calcium-based montmorillonite powder with montmorillonite content ≥ 80%, total cation exchange (CEC) of 1.0 mmol / g montmorillonite powder, and d001 value of 1.42 nm. Add the destoned powder into the electric heating oil bath high-speed mixing mixer, stir and heat to 85°C, then add 0.7mmol of solid cetyltrimethylammonium chloride per g of montmorillonite, and mix at a high speed of 1000r / min under heat preservation Stir and modify for 30 minutes, dry at 105°C to remove excess water and dispersant brought in by quaternary ammonium salts, the drying time is controlled according to the volatile content of the dried material at 105°C ≤ 5%, the modified montmorillonite after drying Further break up and disperse to obtain 325-mesh modified montmorillonite powder with a d001 value of 3.27nm and a loss-on-ignition rate of 20.5% at 850°C as measured by the X-ray diffraction method....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grinding particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com