Controlled release type yeast cell microcapsule product and preparation method thereof

A technology of yeast cells and microcapsules, which is applied in the direction of microcapsule preparation, microsphere preparation, botanical equipment and methods, etc., and can solve the problems of low affinity of water-soluble substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Shake flask cultures of yeast cells were performed as previously described, and the yeast were harvested, washed, and freeze-dried.

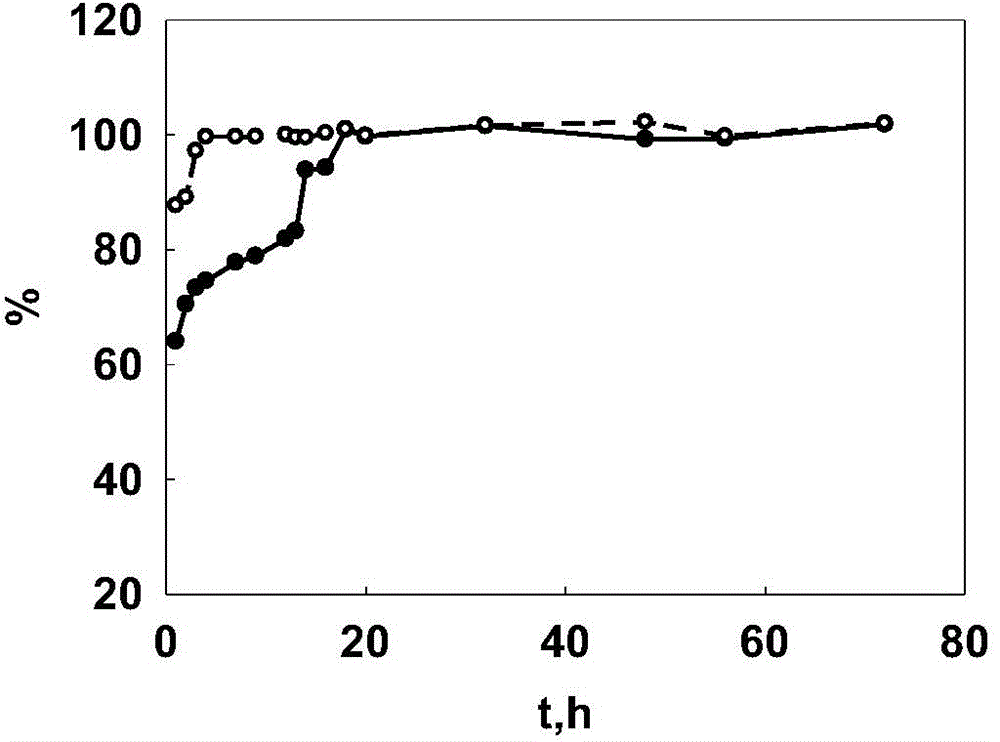

[0071] After contacting 1g of yeast cells with 1-20mL 1% avermectin ethanol solution at 20-40°C for 24 hours at high frequency, centrifuge, wash off the unembedded avermectin on the surface, freeze-dry and grind thin. The embedding degree of abamectin in the microcapsules was determined to be 3.33% by high performance liquid chromatography.

Embodiment 2

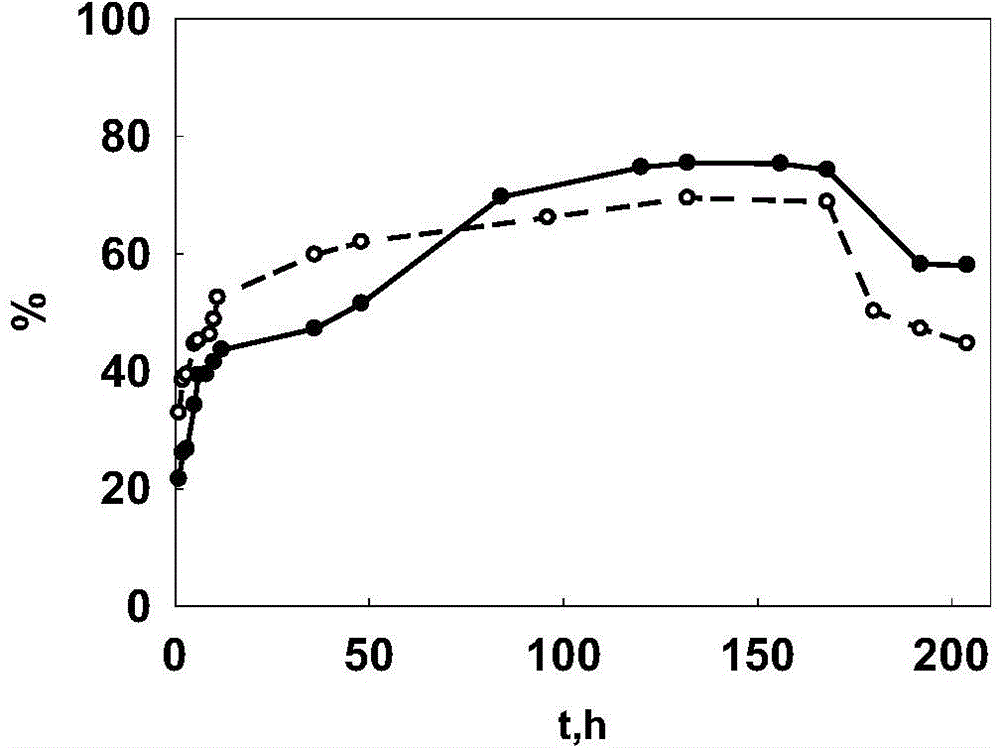

[0075] As mentioned above, culture yeast cells in shake flasks, after centrifugal washing, add 0.5-10% sodium hydroxide by weight, perform shaking treatment at 40-60°C for 24-48 hours, and re-suspend after centrifugal washing Continue shaking treatment in 0.1-10% sodium hydroxide solution at a temperature of 40-60° C. for 24-48 hours, centrifuge, wash, and freeze-dry.

[0076] After 1 g of yeast cells and 1-20 mL of 1% abamectin ethanol solution are contacted at a high frequency at 20-40° C. for 24 hours, they are centrifuged, washed with water to remove unembedded abamectin on the surface, and then freeze-dried.

Embodiment 3

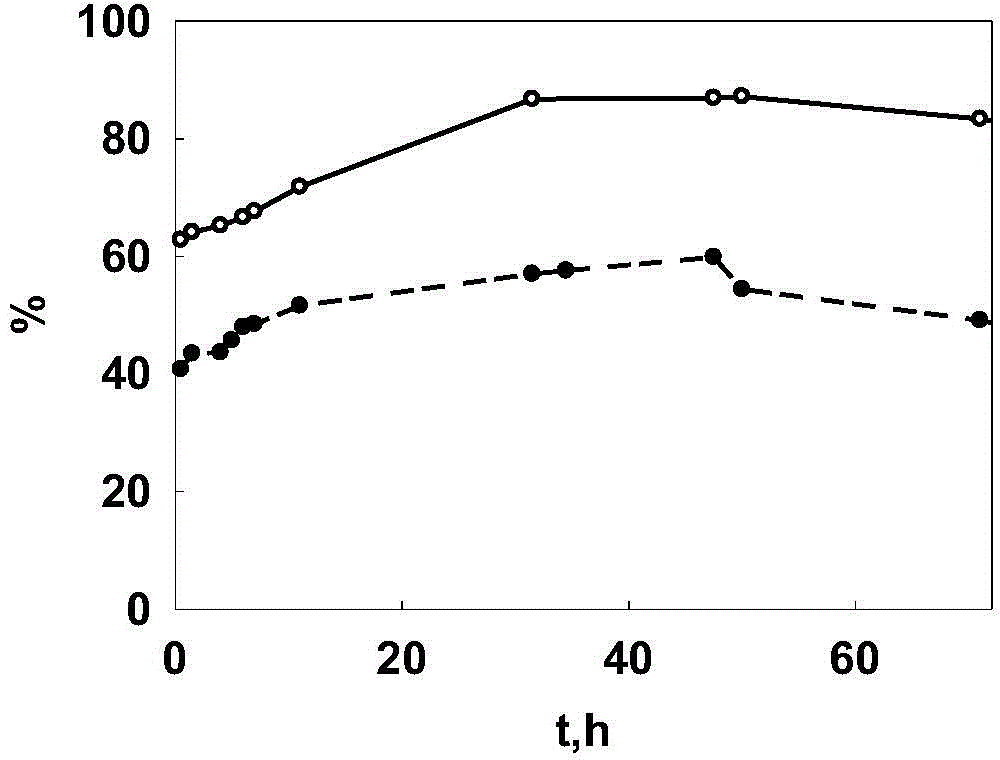

[0080] The steps of culturing, treating yeast and embedding are the same as in Example 1, except that 1-20 mL of 1% quizalofop-p-ethyl ethanol solution is added. The embedding degree of quizalofop-p-ethyl in the obtained microcapsules was 6.75%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of deacetylation | aaaaa | aaaaa |

| cumulative release rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com