Reaction device for reducing potassium fluotantalate by sodium and method for manufacturing tantalum powder by reaction device

A technology of potassium fluorotantalate and tantalum powder is applied in the field of production equipment of tantalum powder, which can solve the problems of environmental pollution, inconvenient opening and closing of valves, large heat capacity, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

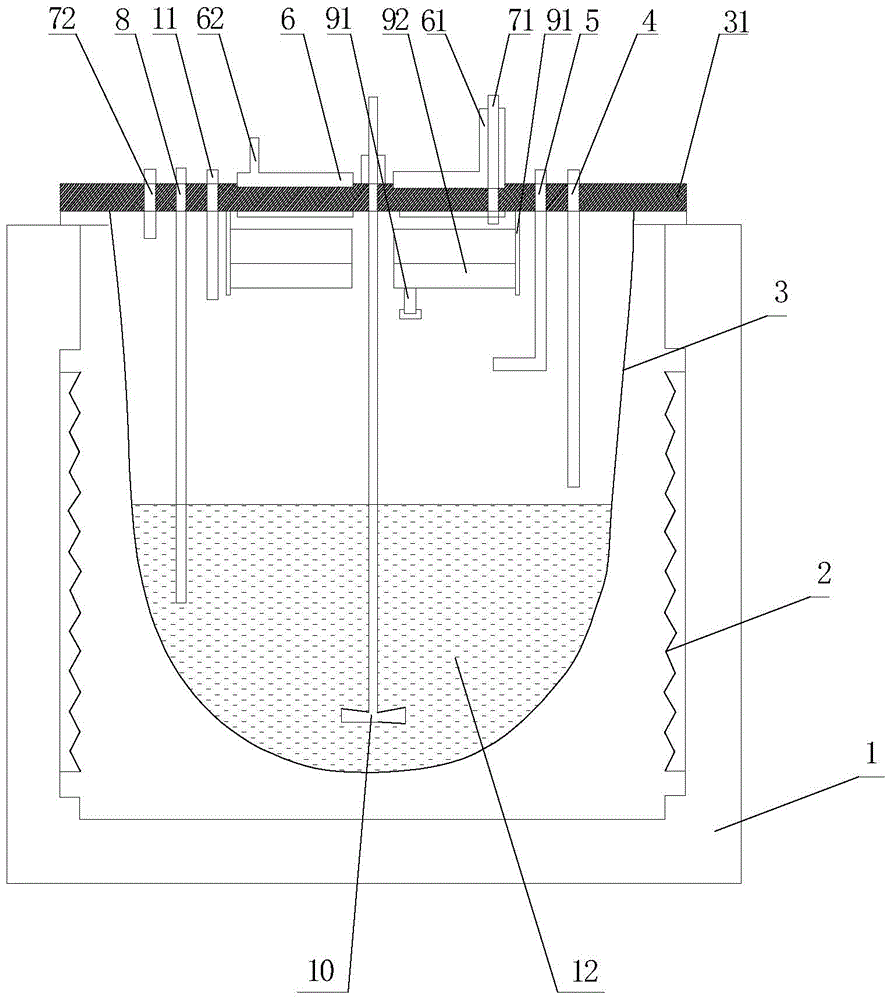

[0058] use as figure 1 In the shown device, 200kg of potassium fluorotantalate and 150kg of sodium chloride are put into the sodium reduction reaction vessel 3-0, and argon gas is filled from the intake pipe 4 after being evacuated from the exhaust pipe 7-2, and the exhaust gas is opened. The valve of the pipe 7-2 is used for circulation, and the air flow rate is 0.1-10 liters / powder. The material 12 in the reaction vessel 3 is heated up to 960° C. with the resistance heater 2, and the stirring paddle 10 is started. 5 injections of sodium, and a total of 60.92kg of metallic sodium were injected to complete the reaction. Let the coolant enter from the inlet 61, pass through the channel 63, and discharge from the outlet 62; close the valve of the exhaust pipe 72, open the valve of the exhaust pipe 71, keep the pressure in the reaction vessel at about 0.1-0.105MPa, and the flow rate of the exhaust gas 0.1-5 liters / minute, continue to stir for 10 minutes, and keep warm at 960°C f...

Embodiment 2

[0062] use as figure 1 In the shown device, 160kg of potassium fluorotantalate, 100kg of sodium chloride and 60kg of potassium chloride and a small amount of oxygen-containing compound grain refiner dissolved in alkali metal halide salt are packed into the sodium reduction reaction vessel 3, After being evacuated from the exhaust pipe 72, fill the argon gas from the intake pipe 4, open the valve of the exhaust pipe 72 to circulate, the gas flow rate is 0.1 liters / minute-10 liters / minute, and the reaction vessel 3-0 is heated by a resistance heater 2 Inner material 12 is warmed up to 900 ℃, makes stirring paddle 10 stir, starts to inject sodium from sodium injection pipe 5 after being kept warm for 1 hour, injects 48.7kg liquid metal sodium altogether, completes reaction. Make the coolant circulate in the cooler 6-0, close the valve of the exhaust pipe 7-2, open the valve of the exhaust pipe 7-1, keep the pressure in the reaction vessel at about 0.1-0.105MPa, and the flow rate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com