Digital printing color tape for light-color natural fiber textiles as well as preparation method and application of digital printing color tape

A technology of natural fibers and printing ribbons, applied in the field of printing ribbons, can solve the problems of difficult control of moisture content, hidden dangers in safety production, and difficult peeling, etc., and achieves good industrial use effect, simple and convenient use method, and no safe production. hidden effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] A preparation method for a light-colored natural fiber textile digital printing ribbon, comprising the steps of:

[0068] (1) Preparation of light-colored natural fiber textile digital printing ribbon coating material: water-based hot-melt adhesive resin (acrylate emulsion YSZ-10 (special), Guangzhou Yunsheng Environmental Protection Technology Co., Ltd.), which is equivalent to water-based hot-melt Adhesive resin quality 0.5% mineral oil defoamer (Guangzhou Xiangcheng Chemical Co., Ltd.) and Ciba Reactive Black WNN reactive dye (Guangzhou Hongfa Chemical Dyestuff Co., Ltd.) equivalent to 45% water-based hot melt resin quality After being uniformly mixed with water equivalent to 15% of the mass of the water-based hot-melt adhesive resin, a colorant water-based hot-melt adhesive resin mixed coating material is obtained, that is, a light-colored natural fiber textile digital printing ribbon coating material;

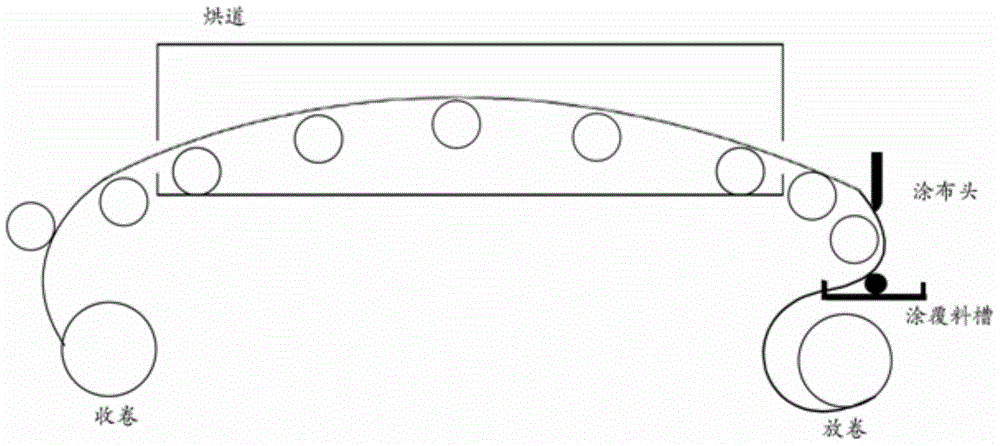

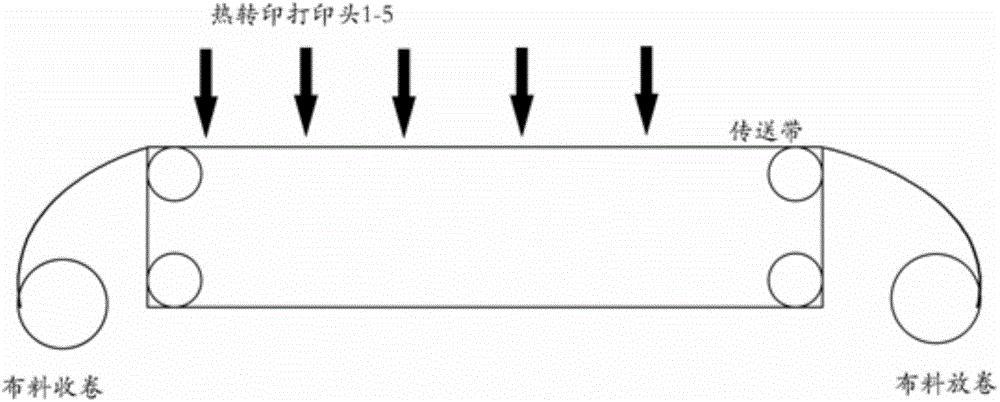

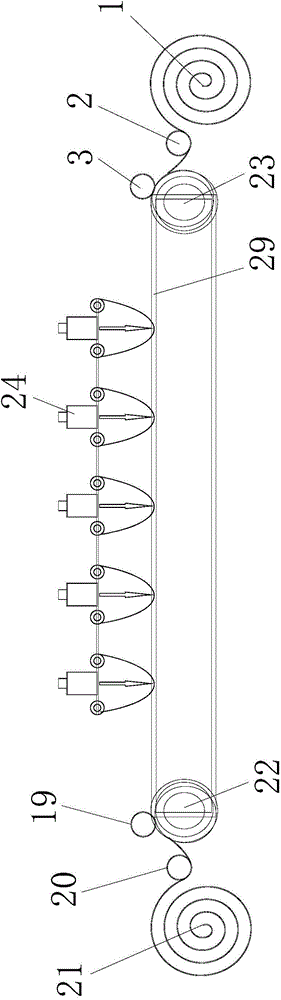

[0069] (2) Coating light-colored natural fiber textile digital...

Embodiment 2

[0077] A preparation method for a light-colored natural fiber textile digital printing ribbon, comprising the steps of:

[0078] (1) Preparation of light-colored natural fiber textile digital printing ribbon coating material: water-based hot-melt adhesive resin (acrylate emulsion YSZ-10 (special), Guangzhou Yunsheng Environmental Protection Technology Co., Ltd.), which is equivalent to water-based hot-melt Adhesive resin quality 0.7% mineral oil defoamer (Guangzhou Xiangcheng Chemical Co., Ltd.) and Ciba Reactive Black WNN reactive dye (Guangzhou Hongfa Chemical Dyestuff Co., Ltd.) equivalent to 10% water-based hot melt resin quality After being uniformly mixed with water equivalent to 10% of the mass of the water-based hot-melt adhesive resin, a colorant water-based hot-melt adhesive resin mixed coating material is obtained, that is, a light-colored natural fiber textile digital printing ribbon coating material;

[0079] (2) Coating light-colored natural fiber textile digital...

Embodiment 3

[0087] A preparation method for a light-colored natural fiber textile digital printing ribbon, comprising the steps of:

[0088] (1) Preparation of light-colored natural fiber textile digital printing ribbon coating material: water-based hot-melt adhesive resin (acrylate emulsion YSZ-10 (special), Guangzhou Yunsheng Environmental Protection Technology Co., Ltd.), which is equivalent to water-based hot-melt Adhesive resin quality 0.6% mineral oil defoamer (Guangzhou Xiangcheng Chemical Co., Ltd.) and Ciba Reactive Black WNN reactive dye (Guangzhou Hongfa Chemical Dyestuff Co., Ltd.) equivalent to 70% water-based hot melt resin quality After mixing evenly with water equivalent to 50% of the mass of the water-based hot-melt adhesive resin, a colorant water-based hot-melt adhesive resin mixed coating material is obtained, that is, a light-colored natural fiber textile digital printing ribbon coating material;

[0089] (2) Coating light-colored natural fiber textile digital printin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com