A kind of preparation method of ultrasensitive nitrogen dioxide sensing material

A technology of nitrogen dioxide and sensing materials, applied in tin oxide, nanotechnology, etc., can solve the problems of poor selectivity, low response, high working temperature, etc., and achieve the effects of easy deviceization, increased output, and good permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

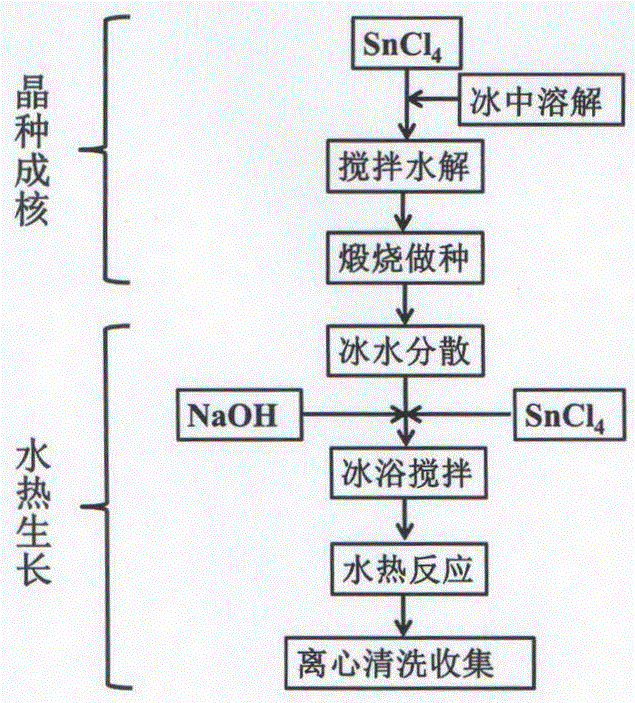

Method used

Image

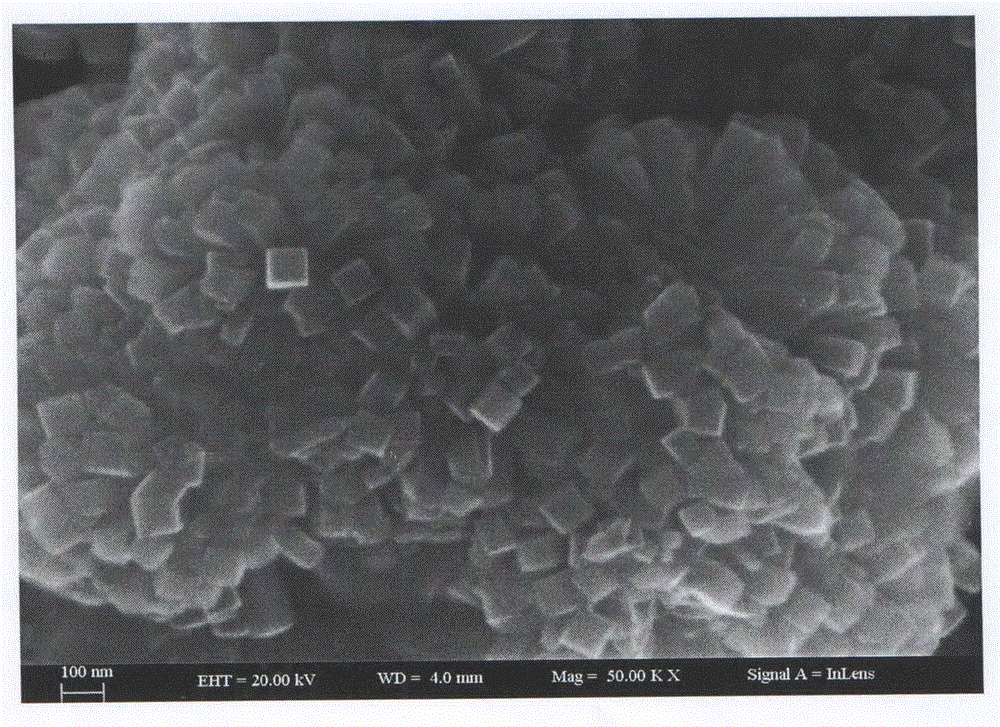

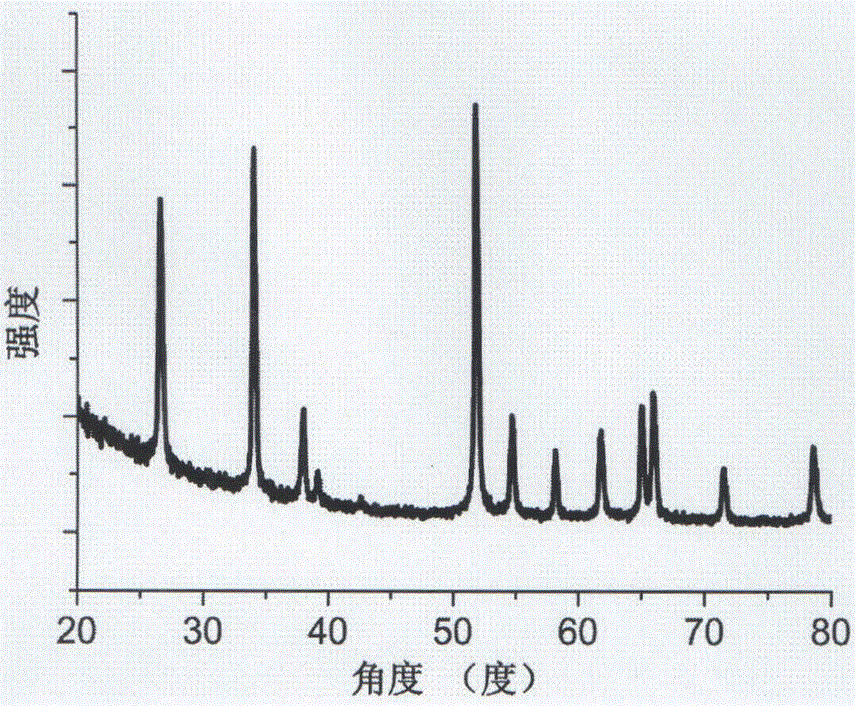

Examples

Embodiment 1

[0033] a. Use a pipette gun to inject 20 μl of tin tetrachloride into 30ml of deionized water frozen ice. After the ice is completely melted, move the solution to a water bath at a temperature of 50°C and stir for 40 hours to make it completely hydrolyzed, and the white precipitate After being collected by centrifugation, it was calcined in an air atmosphere in a tube furnace at a temperature of 500°C for 2 hours to generate tin dioxide nanoparticle crystal seeds;

[0034] b. Grind the seed crystal obtained in step a for 5 minutes with a mortar, then disperse into 30ml deionized ice water and stir, control the temperature of deionized water to 0°C, then add 0.8475g sodium hydroxide and 240μl tin tetrachloride in sequence (the molar ratio is 10.5: 1, wherein the mol ratio of tin tetrachloride in step a and tin tetrachloride in step b is 1: 12), stirred for 30min to form a mixed solution;

[0035] c. Transfer the mixed solution obtained in step b into a Teflon hydrothermal kettl...

Embodiment 2

[0038]a. Inject 20 μl of tin tetrachloride into the ice of deionized water with a pipette gun. After the ice is completely melted, move the solution to a water bath with a temperature of 50°C, stir for 40 hours, and completely hydrolyze. The white precipitate is collected by centrifugation. Finally, calcining in an air atmosphere in a tube furnace at a temperature of 500°C for 2 hours to generate tin dioxide nanoparticle crystal seeds;

[0039] B, grind the seed crystal obtained in step a for 5 minutes with a mortar, then disperse into deionized water and stir, control the temperature of deionized water to be 70°C, then add 0.8475g sodium hydroxide and 240 μl tin tetrachloride (mol Ratio is 10.5: 1, wherein tin tetrachloride in step a and tin tetrachloride mol ratio in step b are 1: 12), stirred 30min to form mixed solution;

[0040] c. Transfer the mixed solution obtained in step b into a Teflon hydrothermal kettle, and place it in an oven at a temperature of 200° C. for 20 h...

Embodiment 3

[0043] a. Use a pipette gun to inject 20 μl of tin tetrachloride into 30ml of deionized water frozen ice. After the ice is completely melted, move the solution to a water bath at a temperature of 30°C and stir for 40 hours to make it completely hydrolyzed, and the white precipitate After being collected by centrifugation, it was calcined in an air atmosphere in a tube furnace at a temperature of 350°C for 2 hours to generate tin dioxide nanoparticle seeds;

[0044] b. Grind the seed crystal obtained in step a for 5 minutes with a mortar, then disperse into 30ml of deionized ice water and stir, control the temperature of deionized water to 0°C, then add 0.5470g of sodium hydroxide and 200μl of tin tetrachloride in sequence (the molar ratio is 8: 1, wherein the mol ratio of tin tetrachloride in step a and tin tetrachloride in step b is 1: 10), stirred for 30min to form a mixed solution;

[0045] c. Transfer the mixed solution obtained in step b into a Teflon hydrothermal kettle,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com