Method for preparing manganese dioxide nano-material with high ammonia gas specific response

A nano-manganese dioxide, specific technology, applied in manganese oxide/manganese hydroxide, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problems of harsh reaction conditions and large impact, and achieve mild conditions , broad development prospects and application space, and the effect of product shape stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0036] A method for preparing a nano-manganese dioxide material with a specific response to ammonia, the specific steps are as follows:

[0037] (1) Solution configuration: use deionized water as solvent, prepare 0.01mol / L potassium permanganate solution and 0.015mol / L sodium sulfite solution 8ml each, and mix them.

[0038] (2) Synthesis of rod-shaped manganese dioxide nanomaterials:

[0039] Put the potassium permanganate solution and the sodium sulfite solution into a 20ml reaction kettle, add 0.01g of polyvinylpyrrolidone (PVP) as a surfactant, and mix them uniformly by ultrasonication for 5 minutes. Put it into an oven and keep it warm at 180° C. for 4 hours to obtain a nano-manganese dioxide material with specific response to ammonia.

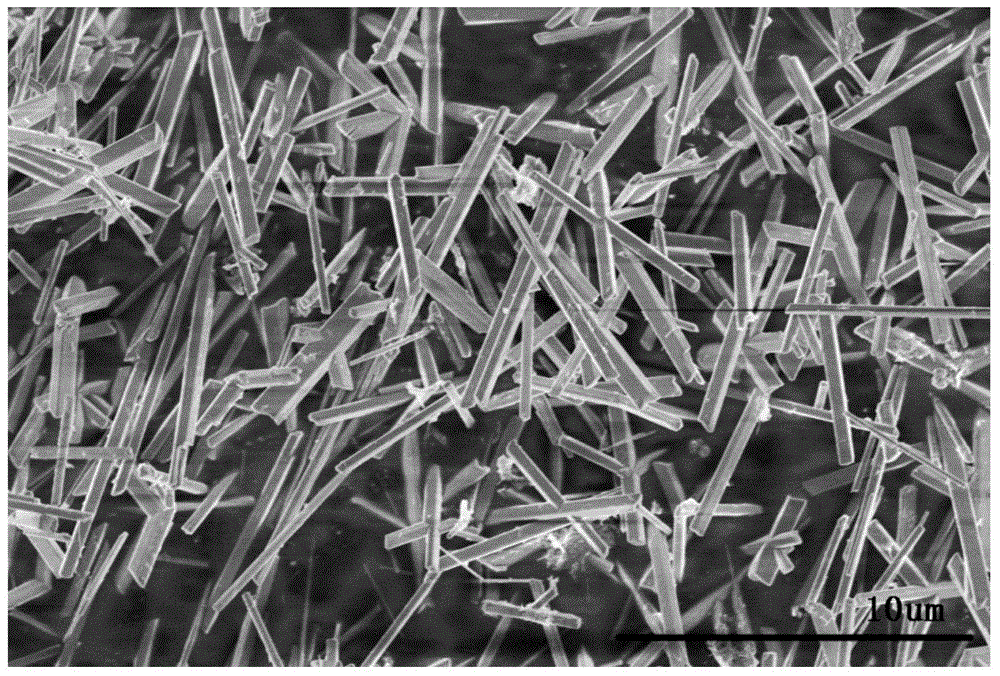

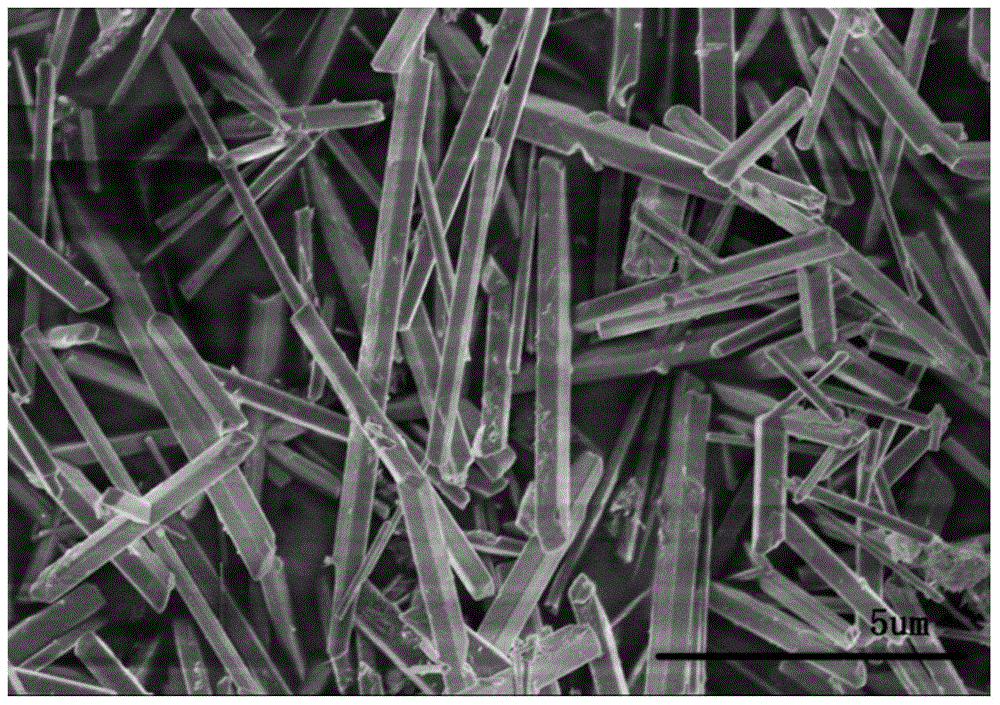

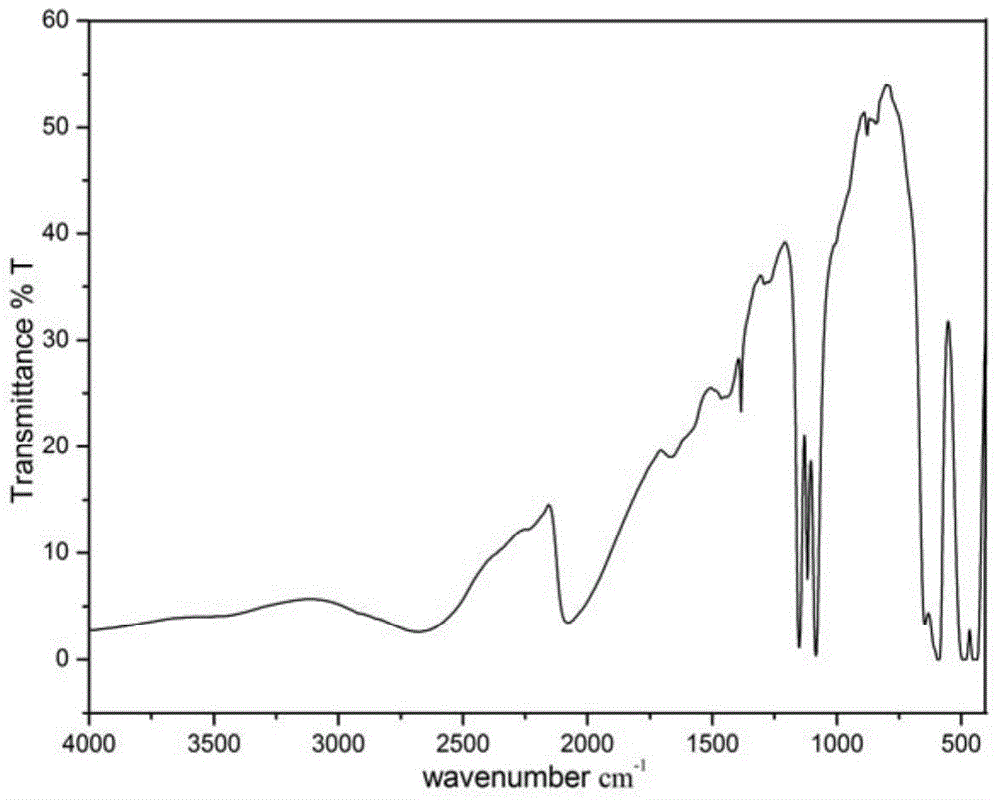

[0040] figure 1 Obtain the SEM photo of the product for the product at a multiple of 5um; figure 2 The SEM photo of the product was obtained at a multiple of 10um. From the above picture, we can see that the cross-sectional diameter o...

Embodiment 2

[0043] A method for preparing a nano-manganese dioxide material with specific response to ammonia, comprising the following steps:

[0044] (1) Configuration of the solution: use deionized water as a solvent, configure a potassium permanganate solution with a concentration of 0.01mol / L and a sodium sulfite solution with a concentration of 0.01mol / L, and mix them in the same volume;

[0045] (2) Synthesis of rod-shaped manganese dioxide nanomaterials: put potassium permanganate solution and sodium sulfite solution into the reactor, add polyvinylpyrrolidone (PVP) as surfactant, surfactant polyvinylpyrrolidone The mass ratio of ketone to potassium permanganate solution is 1:1. Ultrasound for 15 minutes to make it evenly mixed, put it in an oven, and keep it warm at 160°C for 5 hours. After the reaction is over, cool it to room temperature, centrifuge the sample, and wash it. , dry, and collect the product to obtain a nano manganese dioxide material with specific response to ammonia...

Embodiment 3

[0047] A method for preparing a nano-manganese dioxide material with specific response to ammonia, comprising the following steps:

[0048] (1) Configuration of the solution: with deionized water as a solvent, configure a potassium permanganate solution with a concentration of 0.02mol / L and a sodium sulfite solution with a concentration of 0.02mol / L, and mix them in the same volume;

[0049] (2) Synthesis of rod-shaped manganese dioxide nanomaterials: put potassium permanganate solution and sodium sulfite solution into the reactor, add polyvinylpyrrolidone (PVP) as surfactant, surfactant polyvinylpyrrolidone The mass ratio of ketone to potassium permanganate solution is 1:2, ultrasonically mix it for 30 minutes, put it in an oven, and keep it warm at 200°C for 3 hours, after the reaction is over, cool to room temperature, centrifuge and wash the sample , dry, and collect the product to obtain a nano manganese dioxide material with specific response to ammonia.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com