Modified hydroxyethyl cellulose tackifier for well drilling and preparation method thereof

A technology of hydroxyethyl cellulose and tackifier, applied in the polymer field, can solve the problems of poor salt resistance and loss of tackifier, and achieve the effects of tackifier, simple preparation method and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] In a 500ml three-neck flask, 30g of hydroxyethylcellulose and 10g of sodium p-styrenesulfonate were fully dissolved in 300ml of deionized water to obtain a reaction solution. Accurately weigh 0.2 g of ammonium persulfate, fully dissolve it with 20 ml of deionized water and transfer the solution to a constant pressure separatory funnel. Nitrogen was blown into the reaction flask to remove air, and the temperature of the system was raised to 50°C. The ammonium persulfate solution was added dropwise through a constant pressure separatory funnel for reaction. After 8 hours, the reacted mixed solution was immersed in sufficient acetone for precipitation to obtain a polymer. Dry and grind into powder to obtain the graft copolymer of hydroxyethyl cellulose / sodium p-styrene sulfonate.

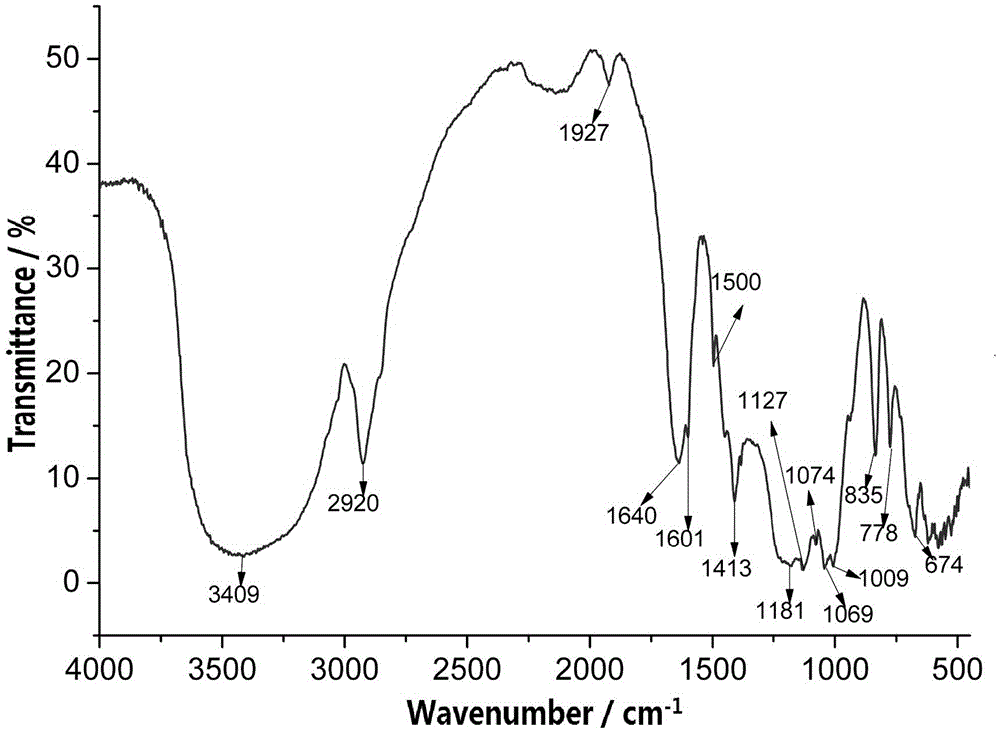

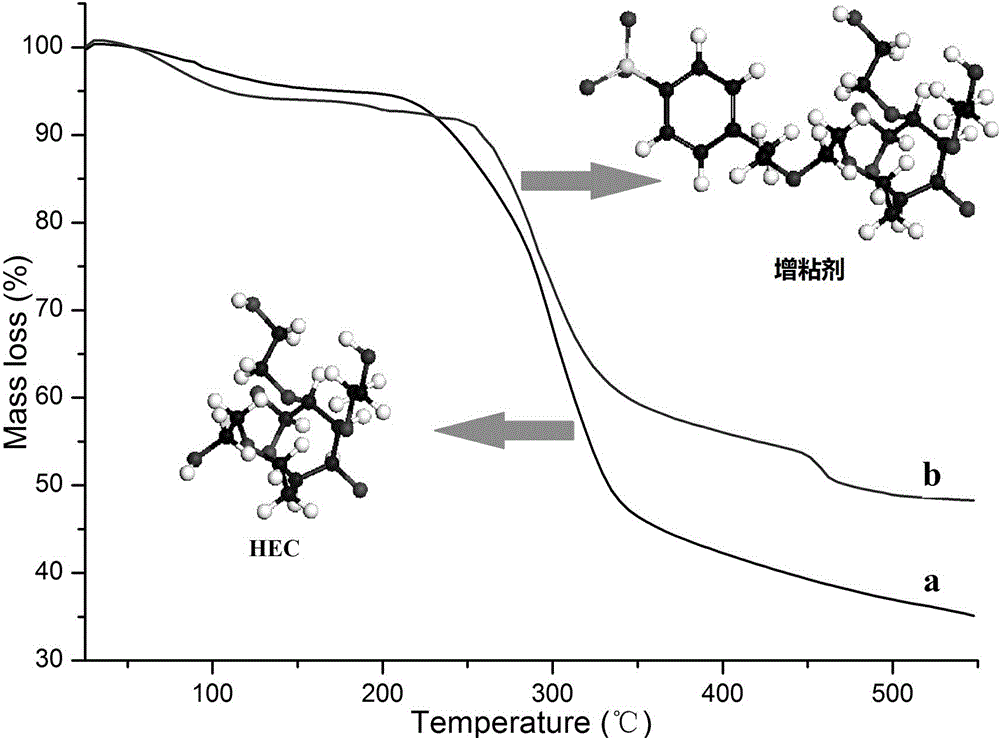

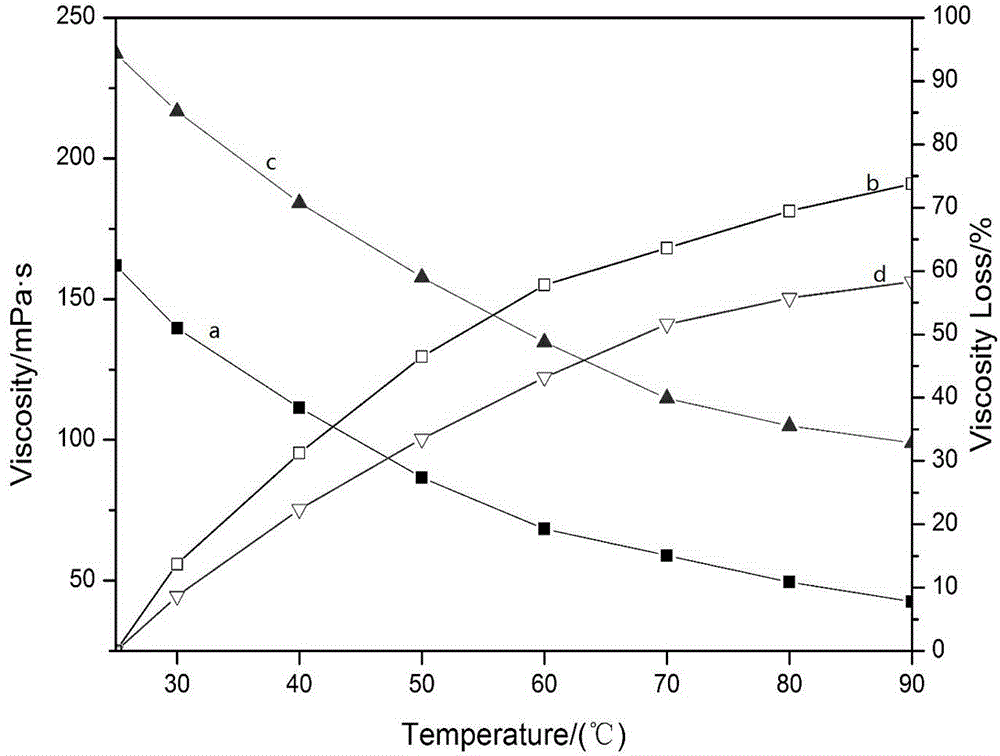

[0031] 2. Infrared Spectrum Test and Analysis of Modified Hydroxyethyl Cellulose Viscosifier for Well Drilling

[0032] figure 1 It is the Fourier transform infrared spectrum test of the tack...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com