A kind of probiotics cereal drink and powder and preparation method thereof

A cereal beverage and probiotic technology, which is applied to bacteria, lactobacillus, bifidobacteria and other directions used in food preparation, can solve the problem of uneven nutrient absorption and metabolite secretion in bacterial growth, and low degree of mechanization in solid-state fermentation production. , the lack of online sensing instruments and other problems, to achieve the effect of large market development potential, unique taste, and a wide range of raw material choices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

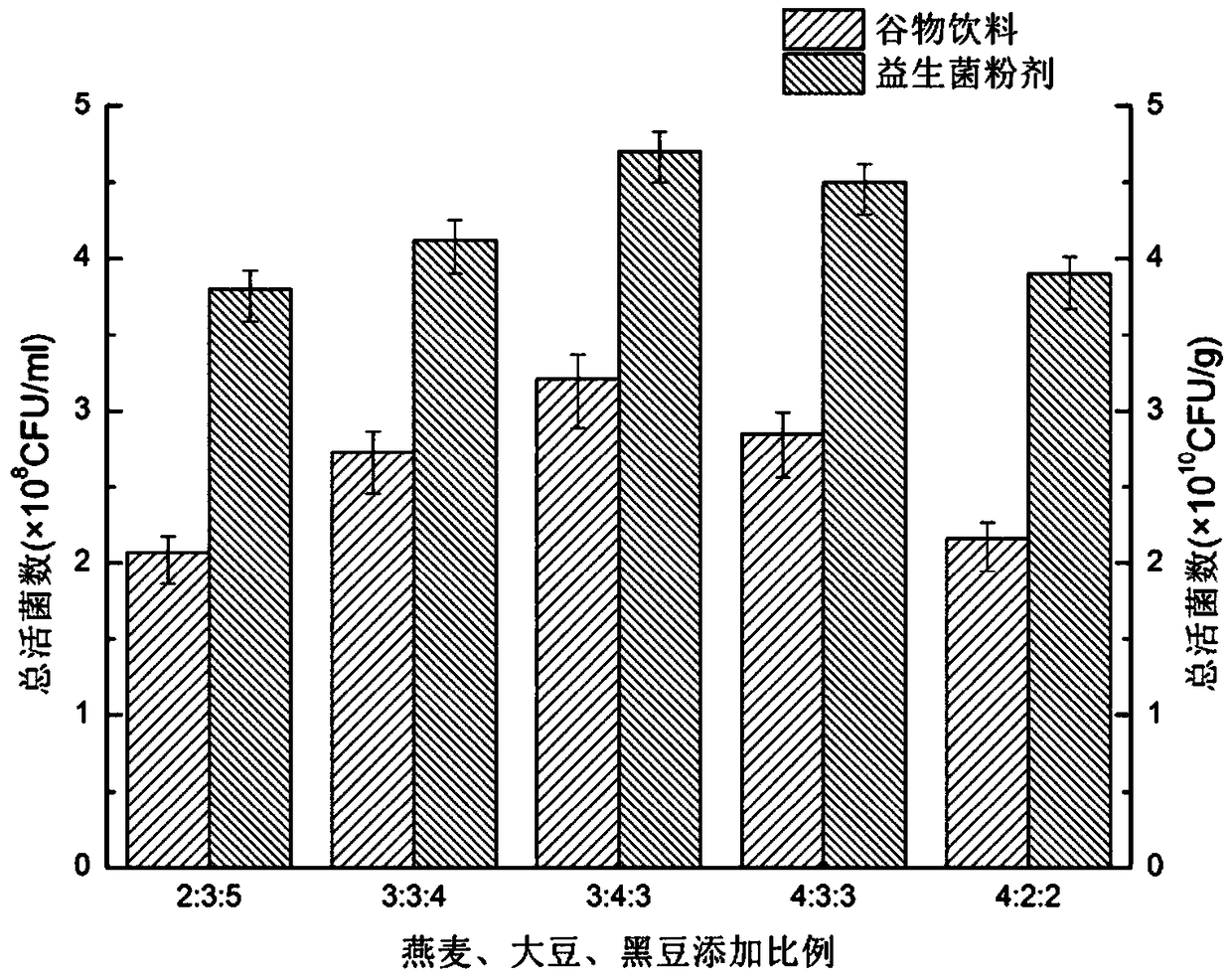

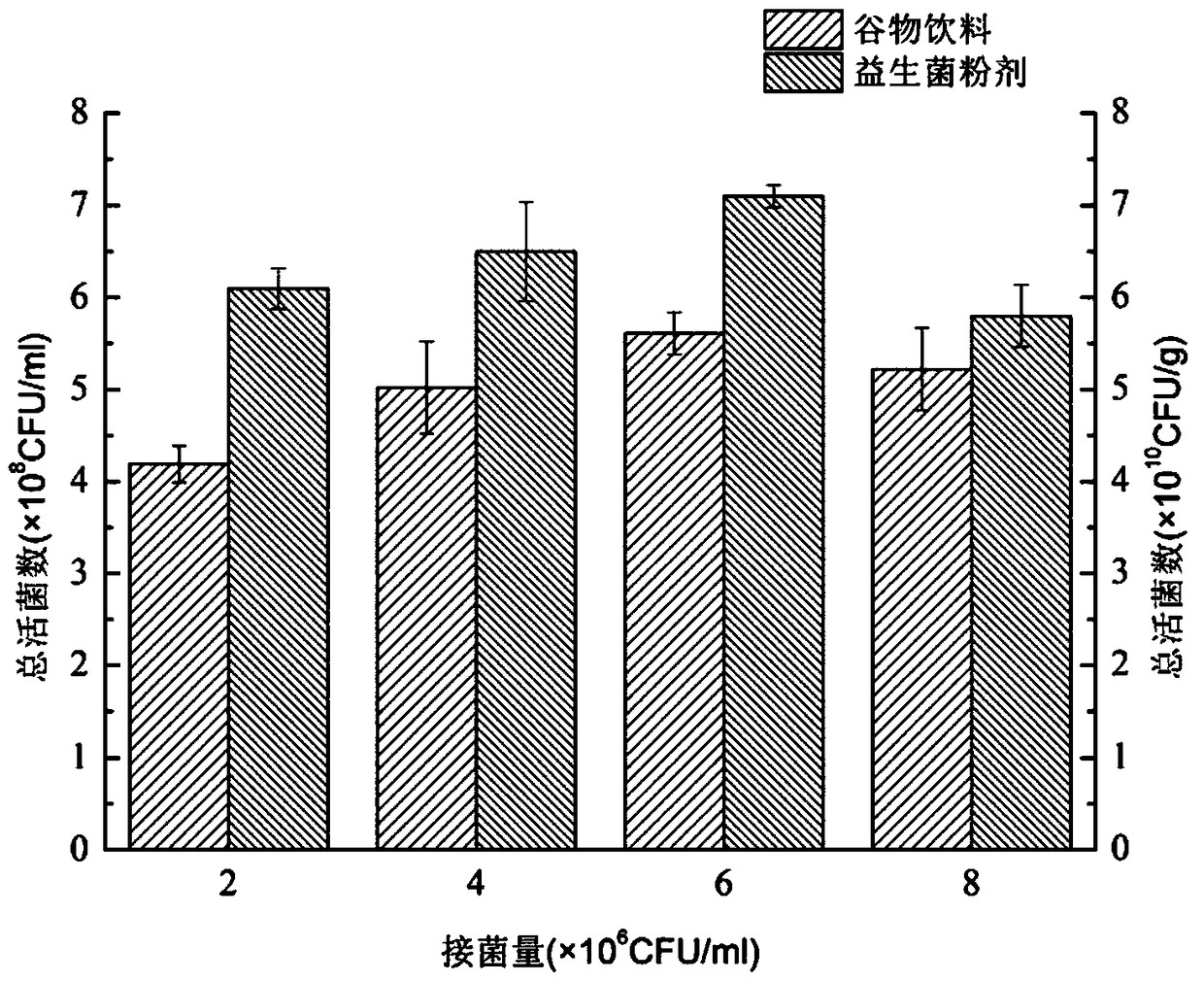

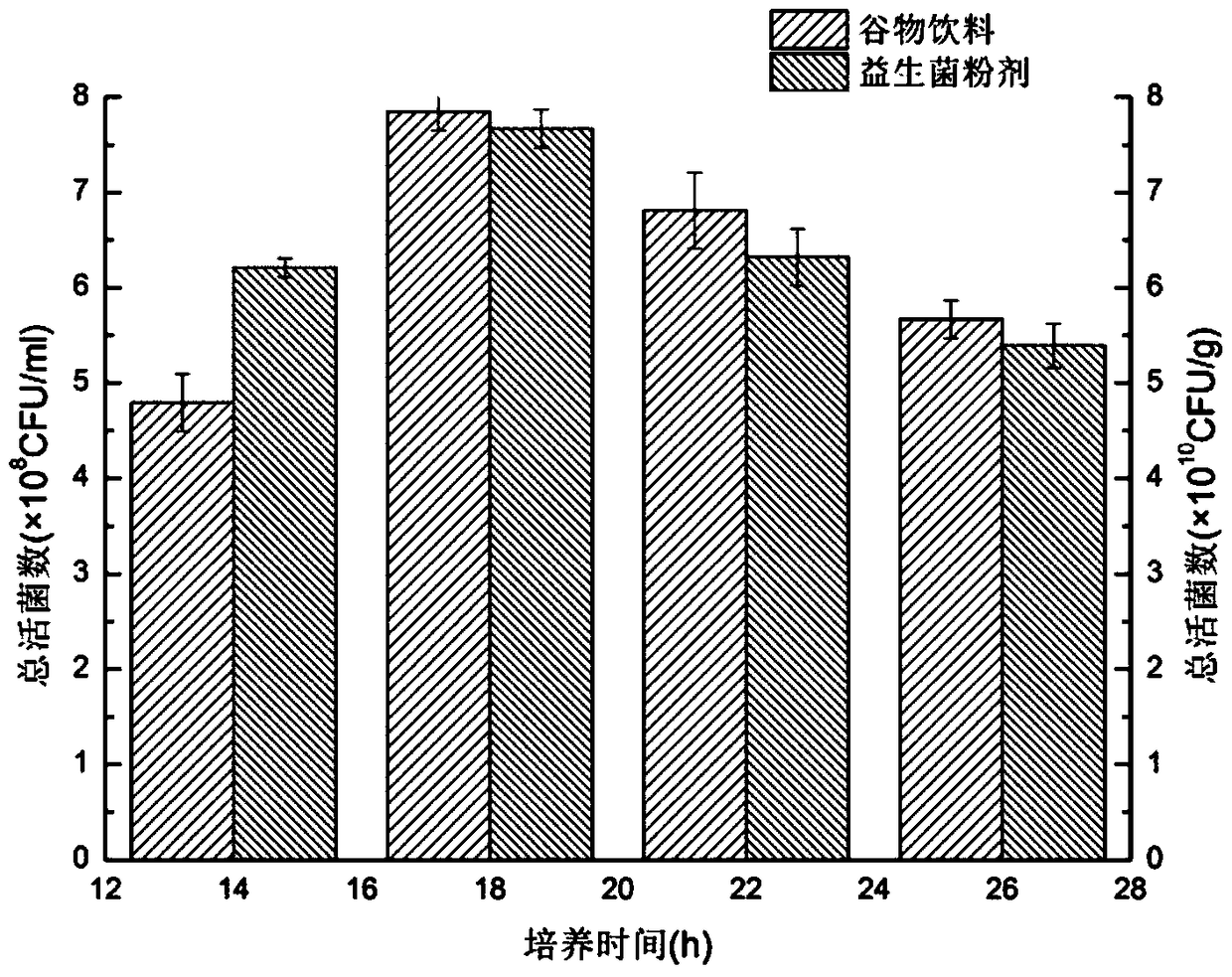

[0037] A kind of probiotics cereal beverage and powder, the raw material of active ingredient per 1000ml water is composed of: 10% cereals, amylase 45u / ml, protease 110u / ml, probiotics inoculated: Lactobacillus plantarum (CGMCC1.6971, CGMCC: Chinese common Microbial Culture Collection Management Center) and Bifidobacterium animalis (CGMCC 1.3003), of which Lactobacillus plantarum 6×10 6 CFU / ml, Bifidobacterium animalis 6×10 6CFU / ml, the cereal is composed of oats, soybeans and black beans, 10.5 parts by weight of oats, 14 parts of soybeans, and 10.5 parts of black beans.

[0038] The preparation method of the above-mentioned probiotic cereal beverage and powder, the specific steps are as follows:

[0039] (1) After the grain is cleaned, it is pulverized by a beater;

[0040] (2) Add amylase and protease to the pulverized feed liquid for enzymolysis after heating, wherein, the amylase addition amount is 45u / ml, the enzymolysis conditions are 63°C, 70min, the protease addition...

Embodiment 2

[0046] A kind of probiotics cereal beverage and powder, the raw material composition of the active ingredient per 1000ml of water is: 8% of cereals, amylase 50u / ml, protease 100u / ml, inoculated with probiotics: Lactobacillus plantarum (CGMCC1.3921) and Bifidus bifidus Bacillus (CGMCC 1.1852), of which Lactobacillus plantarum 10 6 CFU / ml, Bifidobacterium animalis 10 6 CFU / ml, the cereal is composed of oats, soybeans and black beans, 15 parts by weight of oats, 10 parts of soybeans, and 15 parts of black beans.

[0047] The preparation method of the above-mentioned probiotic cereal beverage and powder, the specific steps are as follows:

[0048] (1) After the grain is cleaned, it is pulverized by a beater;

[0049] (2) Add amylase and protease to the pulverized feed liquid for enzymolysis after heating, wherein the amylase addition amount is 50u / ml, the enzymolysis conditions are 60°C and 80min, the protease addition amount is 100u / ml, and the enzyme The hydrolysis conditions...

Embodiment 3

[0055] A kind of probiotics cereal beverage and powder, the raw material composition of the active ingredient per 1000ml of water is: 12% of cereals, 40u / ml of amylase, 120u / ml of protease, inoculated with probiotics: Lactobacillus plantarum (CGMCC1.3915) and animal Bifidobacterium Bacillus (CGMCC 1.1852), of which Lactobacillus plantarum 10 7 CFU / ml, Bifidobacterium animalis 10 7 CFU / ml, the cereal is composed of oats, soybeans and black beans, 12 parts by weight of oats, 13 parts of soybeans, and 11 parts of black beans.

[0056] The preparation method of the above-mentioned probiotic cereal beverage and powder, the specific steps are as follows:

[0057] (1) After the grain is cleaned, it is pulverized by a beater;

[0058] (2) Add amylase and protease to the pulverized feed liquid for enzymolysis after heating, wherein the amylase addition amount is 40u / ml, the enzymolysis conditions are 65°C and 60min, the protease addition amount is 120u / ml, and the enzyme The hydroly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com