Flaky zinc powder preparation method

A scaly zinc powder and zinc powder technology, applied in the field of metallurgy, can solve problems such as low efficiency and long process flow, and achieve the effects of good dispersion performance, high flaky degree and shortened production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

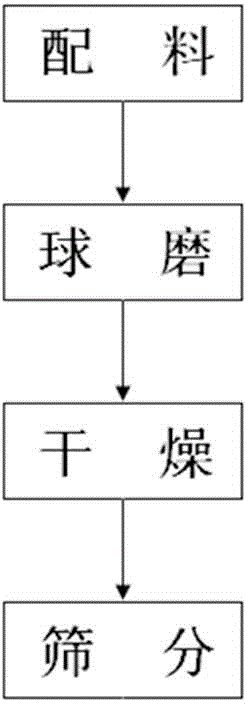

[0012] The preparation method of the flaky zinc powder of the present invention includes the steps of batching, ball milling, drying, and sieving, and specifically includes:

[0013] A. Ingredients: Use atomized spherical zinc powder with a particle size of less than 325 mesh as raw material, add steel balls with a zinc powder weight ratio of 10-20:1, and add a grinding aid and a surface modifier with a zinc powder weight percentage of 1 to 3 to obtain Material a;

[0014] B. Ball milling: Place material a in a ball mill, add material a with a solid-liquid mass ratio of 1:5-6 times the volume concentration of 99% ethanol solution for ball milling to obtain material b;

[0015] C. Drying: Dry material b to constant weight;

[0016] D. Screening: The dried material b is classified by cyclone classification system to obtain the target.

[0017] The diameters of the steel balls mentioned in step A are φ20mm and φ12mm respectively, and the number ratio is 1:3.

[0018] The grinding aid in st...

Embodiment 1

[0024] 1. Put 200g -325 mesh (ie less than 325 mesh) atomized spherical zinc powder, 3000g steel ball, 3g stearic acid, 3g polyvinyl alcohol, and 1000g volume concentration of 99% ethanol into the ball mill tank;

[0025] 2. The rotating speed of the ball mill is 1500 rpm, and the ball milling time is 6 hours;

[0026] 3. Put the ball-milled zinc powder in a vacuum drying oven and dry it at 70~80℃;

[0027] 4. The dried zinc powder was classified by a cyclone classification system, and the average particle size of phosphorous flake zinc powder was D(50)=22.4μm, the degree of flake formation was 93%, and the diameter-to-thickness ratio was 47.

Embodiment 2

[0029] 1. Put 200g -325 mesh atomized spherical zinc powder, 4000g steel ball, 3g stearic acid, 3g sodium dodecylbenzene sulfonate, and 1000g volume concentration of 99% ethanol into the ball mill;

[0030] 2. The rotating speed of the ball mill is 1500 rpm, and the ball milling time is 6 hours;

[0031] 3. Put the ball-milled zinc powder in a vacuum drying oven and dry it at 70~80℃;

[0032] 4. The dried zinc powder was classified by a cyclone classification system, and the average particle size of phosphorous flake zinc powder was D(50)=16.8μm, the degree of flake formation was 95%, and the diameter-to-thickness ratio was 52.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com