Continuous fermentation device for biscuit food

A continuous, food technology, applied in the field of biscuits, can solve the problems of indigestion and absorption of coarse grains, high unsaturated fat content, lack of nutritional and health care functions, etc., to achieve good market prospects and promotion value, unique taste, and reduce labor costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

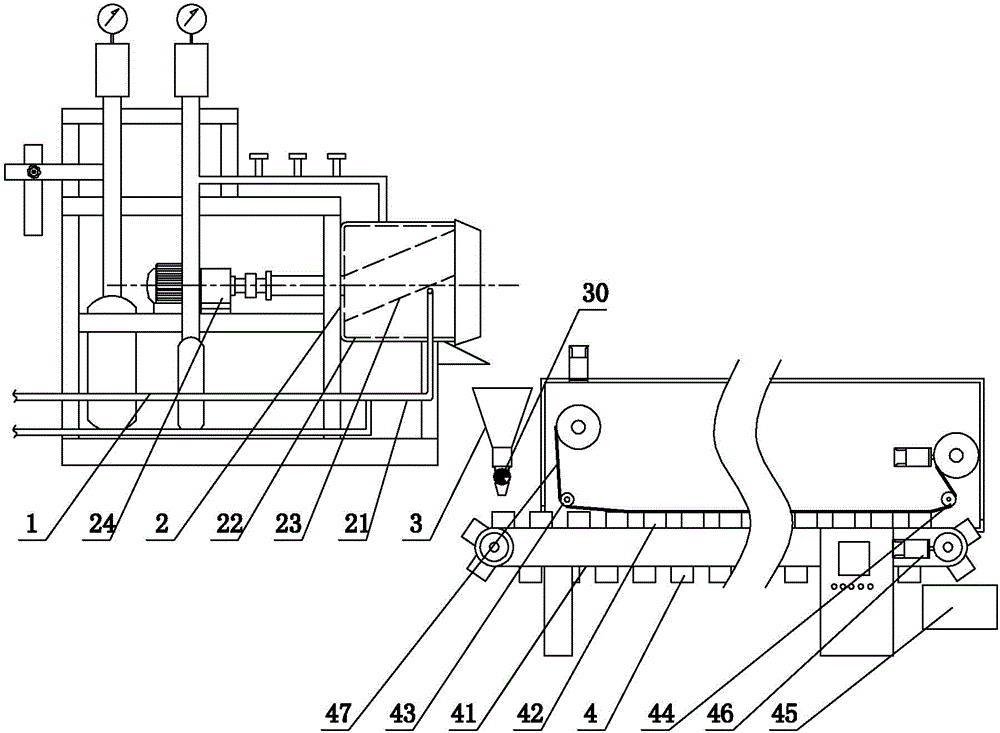

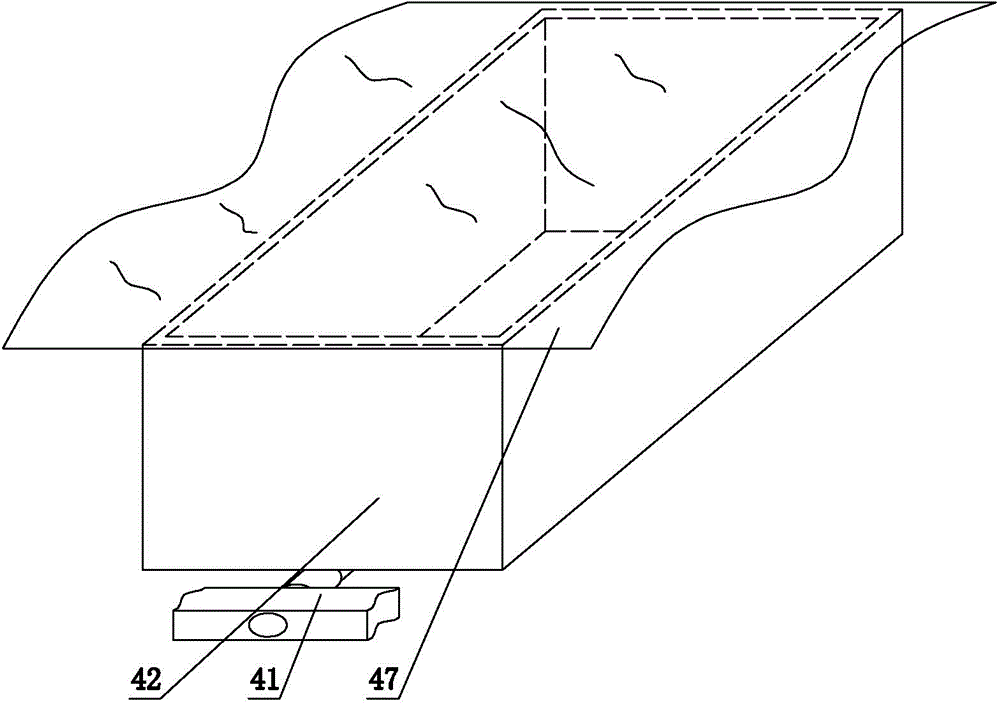

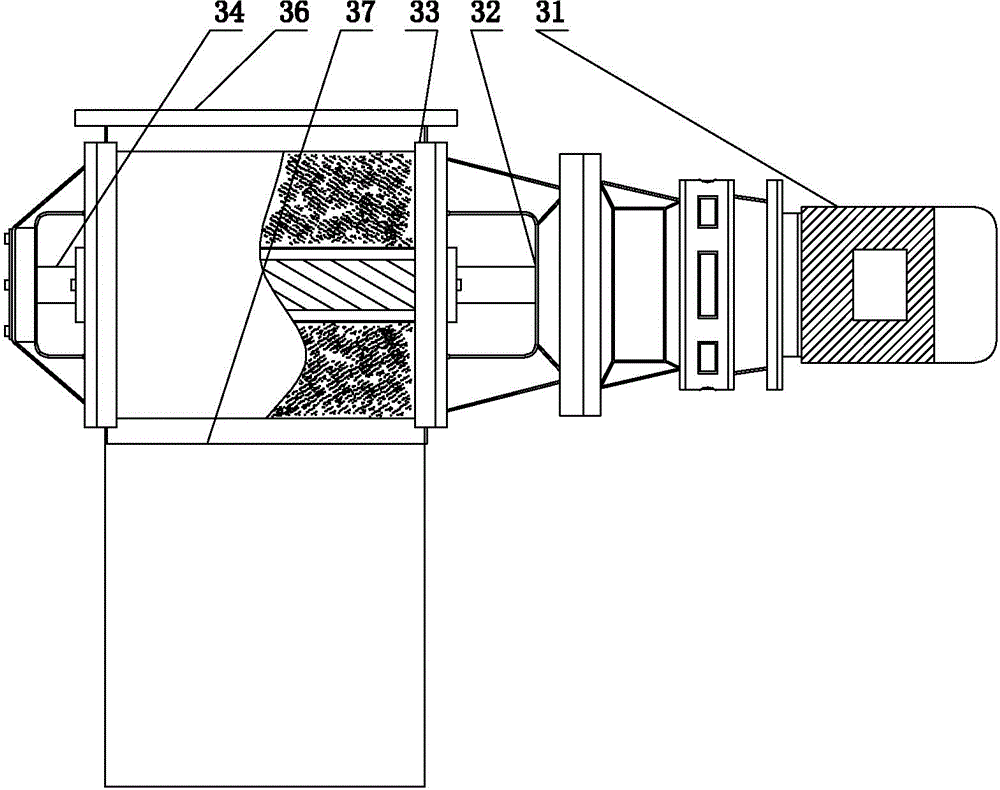

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: the preparation method of this biscuit food is:

[0036] 1. Put 85 parts of oats, 14 parts of wheat bran, 0.3 parts of pectin and 20 parts of water into a solid continuous fermentation reaction device, cook and sterilize at 95°C for 3 minutes and cool to 22°C, then pour into the tank where the device is located Internally inoculate 0.0003 parts of papain, 0.025 parts of Bacillus subtilis (108cfu / g), 0.6 parts of cellulase, and 0.2 parts of fresh yeast (107cfu / g). 4.5. Ferment at 22°C for 8 hours, filter the obtained reactant A, put it into the solid continuous fermentation reaction device again, inoculate 0.2 parts of active acetic acid bacteria, 0.001 parts of pectinase, and 0.002 parts of bifidobacteria into the tank where the device is located , Lactobacillus (109cfu / g) 0.001 part, the material was sent to the tunnel fermentation line and fermented at pH 4.5 and 22°C for 10 hours, after the fermentation product was filtered, it was heated and inactivate...

Embodiment 2

[0040] Embodiment 2: the preparation method of this biscuit food is:

[0041] 1. Put 95 parts of oats, 15 parts of wheat bran, 0.4 parts of pectin and 25 parts of water into a solid continuous fermentation reaction device, cook and sterilize at 100 ° C for 2.5 minutes and cool to 26 ° C, then pour into the tank where the device is located Inoculate 0.0004 parts of papain, 0.037 parts of Bacillus subtilis, 0.9 parts of cellulase, and 0.25 parts of fresh yeast. After stirring, the materials are sent to the tunnel fermentation line and fermented at pH 5.3 and 27°C for 10 hours. After filtering the obtained reactant A, put it into the solid continuous fermentation reaction device again, and inoculate 0.3 parts of active acetic acid bacteria, 0.0015 parts of pectinase, 0.0025 parts of bifidobacteria, and 0.0015 parts of lactobacillus (109cfu / g) into the tank where the device is located , send the material into the tunnel fermentation line and ferment at pH 5.3 and 27°C for 10 hours...

Embodiment 3

[0045] Embodiment 3: the preparation method of this biscuit food is:

[0046] 1. Put 105 parts of oats, 16 parts of wheat bran, 0.5 parts of pectin and 30 parts of water into a solid continuous fermentation reaction device, cook and sterilize at 105°C for 2 minutes and cool to 30°C, then pour into the tank where the device is located Inoculate 0.0006 parts of papain, 0.05 parts of Bacillus subtilis, 1.2 parts of cellulase, and 0.3 parts of fresh yeast. After stirring, the materials are sent to the tunnel fermentation line and fermented at pH 6 and 32°C for 12 hours. After the obtained reactant A is filtered, put it into the solid continuous fermentation reaction device again, and inoculate 0.4 parts of active acetic acid bacteria, 0.002 parts of pectinase, 0.003 parts of bifidobacteria, and 0.002 parts of lactobacillus (109cfu / g) into the tank where the device is located , feed the material into the tunnel fermentation line and ferment at pH 6, 32°C for 12 hours, filter the fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com