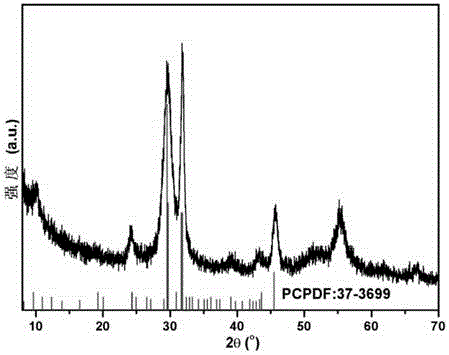

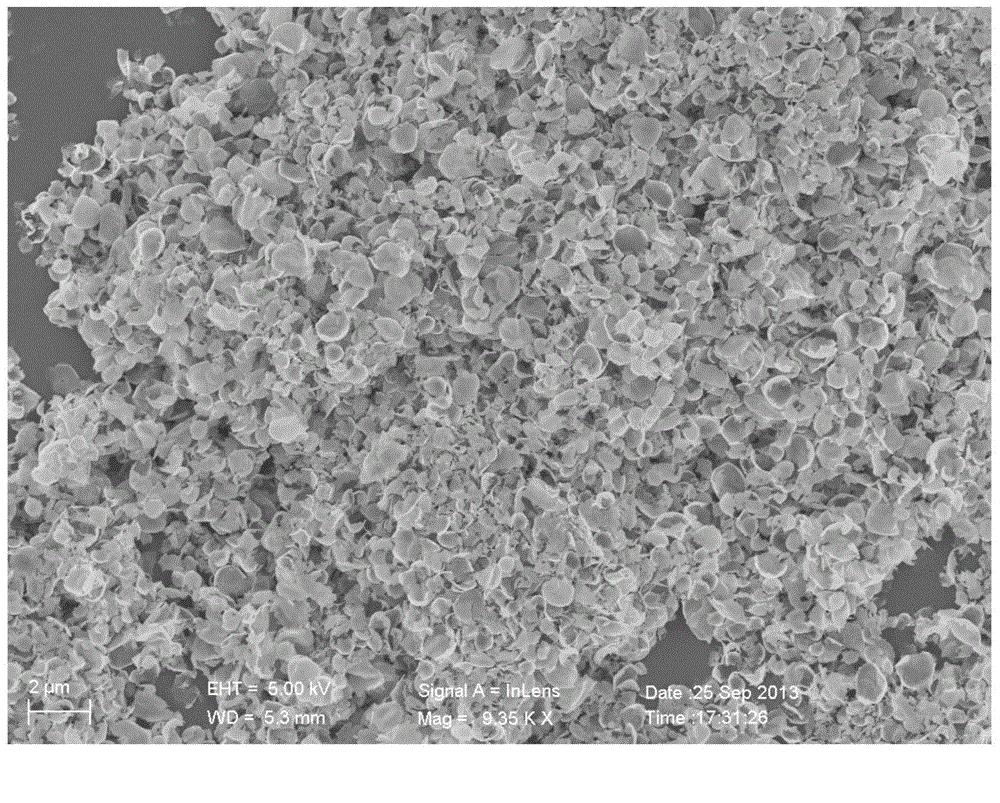

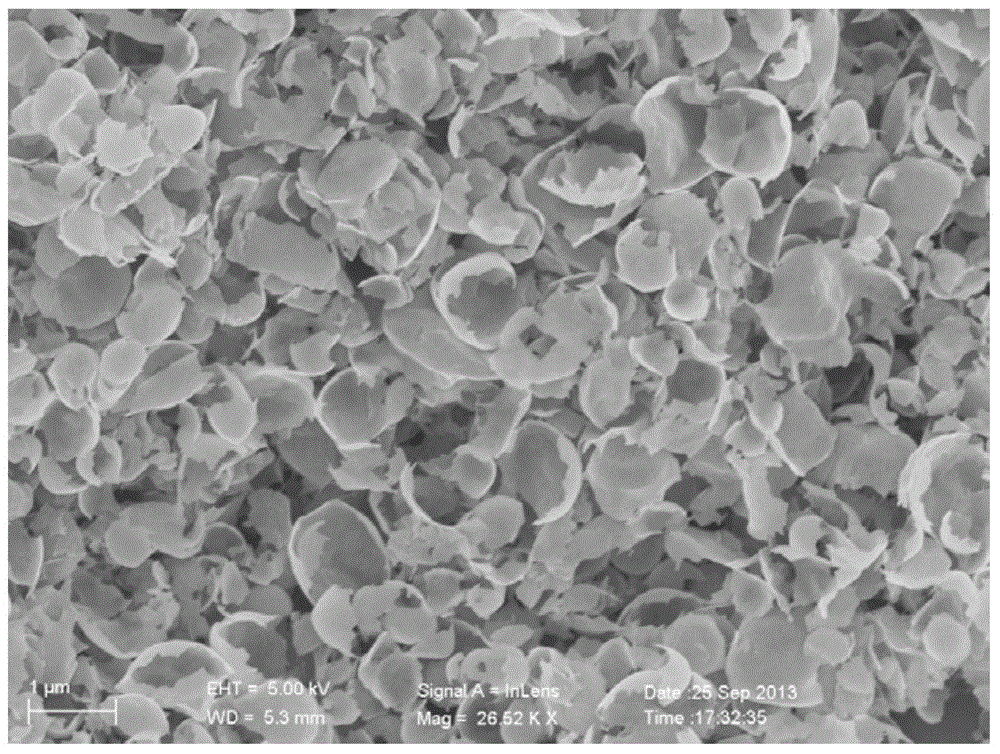

A preparing method of an eggshell-shaped porous Bi4O5Br2 nanometer material

A bi4o5br2, nanomaterial technology, applied in the direction of bromine oxycompound and other directions, can solve the problem of lack of photocatalyst research, and achieve the effects of simple operation, low ambient temperature and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Eggshell-shaped porous Bi of the present invention 4 o 5 Br 2 Nanomaterials are prepared by two-step processes of sonochemical technology and heat treatment. The specific process steps are as follows:

[0025] S1 weighs 1.940g bismuth nitrate Bi(NO 3 ) 3 ·5H 2 O was stirred and hydrolyzed into Sol A with 10mL deionized water;

[0026] S2 weighs 0.2001g cetyltrimethylammonium bromide (CTAB) and prepares solution B with 20mL deionized water, and the molar ratio of bismuth nitrate pentahydrate and CTAB is 1:1.375;

[0027] S3 weighs again 0.7612g thiourea (Tu) and prepares solution C with 30mL deionized water;

[0028] S4 While stirring, add solution B to sol A in turn, then add solution C to the mixed reaction solution of A and B, and continue stirring for 10 minutes;

[0029]S5 Transfer the mixed reaction solution to a 100mL glass bottle with a blue cap, place it in an ultrasonic cleaner filled with tap water, the temperature of the ultrasonic bath is 80°C, and th...

Embodiment 2

[0036] Eggshell-shaped porous Bi of the present invention 4 o 5 Br 2 Nanomaterials are prepared by two-step processes of sonochemical technology and heat treatment. The specific process steps are as follows:

[0037] S1 weighs 1.940g bismuth nitrate Bi(NO 3 ) 3 ·5H 2 O was stirred and hydrolyzed into Sol A with 10mL deionized water;

[0038] S2 Weigh 0.1455g cetyltrimethylammonium bromide (CTAB) and prepare solution B with 20mL deionized water, the molar ratio of bismuth nitrate pentahydrate and CTAB is 1:1;

[0039] S3 weighs again 0.7610g thiourea (Tu) and prepares solution C with 30mL deionized water;

[0040] S4 While stirring, add solution B to sol A in turn, then add solution C to the mixed reaction solution of A and B, and continue stirring for 10 minutes;

[0041] S5 Transfer the mixed reaction solution to a 100mL glass bottle with a blue cap, place it in an ultrasonic cleaner filled with tap water, the temperature of the ultrasonic bath is 60°C, and the ultraso...

Embodiment 3

[0045] Eggshell-shaped porous Bi of the present invention 4 o 5 Br 2 Nanomaterials are prepared by two-step processes of sonochemical technology and heat treatment. The specific process steps are as follows:

[0046] S1 weighs 1.942g bismuth nitrate Bi(NO 3 ) 3 ·5H 2 O was stirred and hydrolyzed into Sol A with 10mL deionized water;

[0047] S2 Weigh 0.2910g cetyltrimethylammonium bromide (CTAB) and prepare solution B with 20mL deionized water, the molar ratio of bismuth nitrate pentahydrate and CTAB is 1:2;

[0048] S3 weighs again 0.7612g thiourea (Tu) and prepares solution C with 30mL deionized water;

[0049] S4 While stirring, add solution B to sol A in turn, then add solution C to the mixed reaction solution of A and B, and continue stirring for 10 minutes;

[0050] S5 Transfer the mixed reaction solution to a 100mL glass bottle with a blue cap, place it in an ultrasonic cleaner filled with tap water, the temperature of the ultrasonic bath is 90°C, and the ultraso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Port diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com