Method of producing calcium formate with calcium chloride and sodium formate

A technology of calcium chloride and calcium formate, applied in chemical instruments and methods, preparation of alkali metal chlorides, organic compounds, etc., can solve problems such as low quality of calcium formate, blockage of production equipment, unstable production, etc., and achieve economical Considerable benefits, non-corrosive and irritating, low raw material cost and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

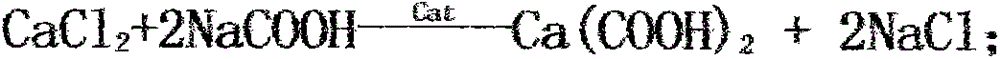

Image

Examples

Embodiment 1

[0013] 1) Reaction: Add 178g of sodium formate powder raw material containing 80% sodium formate to the reaction cup, dissolve it in 162g of water, add 150ml of mother liquor, after heating to 50°C, add 90% calcium chloride containing 90% calcium chloride to the reaction cup under constant stirring. 123g of calcium chloride raw material powder was reacted for 2 hours under the catalysis of nickel-based catalyst, and the high-quality feed grade calcium formate product was obtained through concentration, crystallization, filtration, washing and drying.

[0014] 2) Extraction and separation: Add 200ml glycerin to the filtered mother liquor, separate the organic phase from the water phase, heat and evaporate the organic phase, recover the organic solvent, and cool the remaining solution to 25°C to crystallize, filter, wash and dry to obtain Industrial Sodium Chloride Products.

[0015] 3) The organic solvent is recovered and recycled, and the mother liquor is returned to the react...

Embodiment 2

[0017] 1) Reaction: Add 158g of sodium formate powder raw material containing 90% sodium formate to the reaction cup, dissolve it in 142g of water, add 150ml of mother liquor, after heating to 40°C, add chlorine containing 85% calcium chloride to the reaction cup under constant stirring. Calcium raw material powder 130g, reacted for 2 hours under the catalysis of nickel-based catalyst, concentrated, crystallized, filtered, washed, dried to obtain high-quality feed grade calcium formate product.

[0018] 2) Extraction and separation: Add 200ml glycerin to the filtered mother liquor, separate the organic phase from the water phase, heat and evaporate the organic phase, recover the organic solvent, and cool the remaining solution to 25°C to crystallize, filter, wash and dry to obtain Industrial Sodium Chloride Products.

[0019] 3) The organic solvent is recovered and recycled, and the mother liquor is returned to the reaction cup for recycling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com