Coating solution for reducing glass surface light reflection

A technology of glass surface and light reflection, applied in the field of chemical engineering, can solve the problems of high manufacturing cost and affecting the anti-aging performance of the film layer, achieve low raw material cost and production cost, high practical application value, and increase the effect of light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

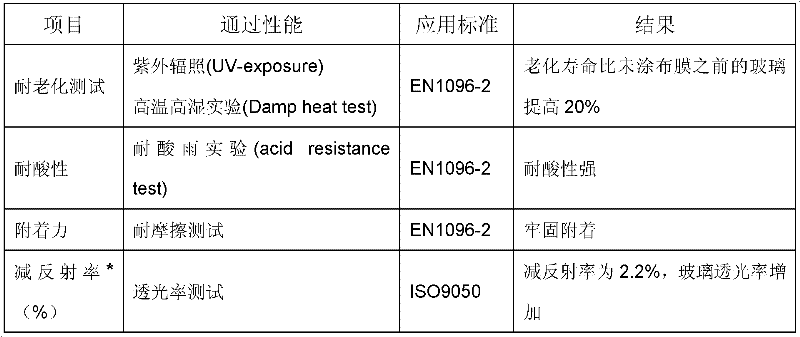

Examples

Embodiment 1

[0032] In the coating solution prepared in this embodiment, the ratio of each raw material component is, ester substance (orthosilicate ethyl ester): water: acid (analytical grade hydrochloric acid): amine reagent (ammonia and tetraethyl ammonium bromide): alcohol solvent (butanol)=1:4:0.05:0.6:15.

[0033] The preparation process of above-mentioned coating solution is: with the material quality of 100L water, calculate various raw materials according to above-mentioned ratio, comprise tetraethylorthosilicate, hydrochloric acid, ammoniacal liquor and tetraethylammonium bromide (ammonia liquor and tetraethylammonium bromide The molar ratio of ammonium is 1:5) and butanol carry out batching.

[0034] Mix the tetraethylammonium bromide, butyl alcohol, water, hydrochloric acid, and ammonia water with a mass ratio of 1: 15: 4: 0.05: 0.1: and add 0.5 molar ratio of tetraethylammonium bromide after stirring. After stirring, the coating solution can be made. Using coating equipment,...

Embodiment 2

[0040] In the coating solution prepared in this embodiment, the ratio of each raw material component is: ester substance: water: acid: amine reagent: alcohol solvent = 1:6:0.1:0.2:15.

[0041] The preparation process of the above-mentioned coating solution is: based on the substance mass of 100L water, various raw materials are calculated according to the above ratio, including butyl zirconate, hydrochloric acid (hydrochloric acid of analytical grade), tetraethylammonium bromide and propanol for batching .

[0042] Mix butyl zirconate, propanol, water, and hydrochloric acid at a mass ratio of 1:15:6:0.1, stir and add tetraethylammonium bromide in a molar ratio of 0.2, and then stir to make coating solution. Using coating equipment, under the conditions of liquid flow rate of 1.2ml / s, air pressure of 3.5bar, distance of 35cm, and spray gun moving speed of 2cm / s, the coating solution is coated on the glass surface, and the coating thickness is less than 200nm. After drying, th...

Embodiment 3

[0049] In the coating solution prepared in this embodiment, the mass ratio of each raw material component is, ester substance (methyl orthosilicate): water: acid (analytical grade acetic acid): amine reagent (N, N -2 methylformamide): alcohol solvent (butanol)=1:5:0.08:0.4:15.

[0050] The preparation process of the above coating solution is: based on the substance mass of 100L water, calculate various raw materials according to the above ratio, including methyl orthosilicate, acetic acid, N, N-2 methyl formamide, water and butanol for batching .

[0051] Mix methyl orthosilicate, butanol, water, acetic acid, and N,N-2 methylformamide according to the above ratio, and stir to prepare a coating solution. Using coating equipment, under the conditions of liquid flow rate of 1.2ml / s, air pressure of 3.5bar, distance of 35cm, and spray gun moving speed of 2cm / s, the coating solution is coated on the glass surface, and the coating thickness is <200nm , after drying, the glass with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com