Production method of non-toxic fireproof waterproof artificial panel and non-toxic panel glue

A production method and sheet technology, applied in chemical instruments and methods, adhesives, layered products, etc., can solve the problems of inaccessibility, increased cost, difficulty in auxiliary film, etc., and achieve wide application, low cost, and reduction of production costs and raw materials. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

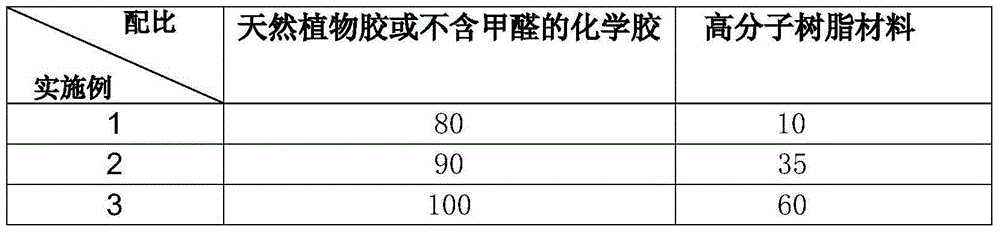

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific embodiments.

[0021] A kind of non-toxic, fire-proof, water-resistant production method of wood-based panel that the preferred embodiment of the present invention proposes, the steps are as follows:

[0022] Step 1: Send the mixed non-toxic board glue to the production workshop. The workshop adjusts the consistency of the non-toxic board glue according to the glue coating process of the wood-based board, weather humidity and temperature, the moisture content of the board and experience. Because the glue is thin, the amount of glue applied is not enough, and the bonding strength of the board is not enough, resulting in cracking or hollowing of the board, which affects the quality of the board. If the glue is thick, the glue layer is too thick, the hot pressing time will be prolonged, the production capacity will be reduced, the energy consumption will be increased, and the glue will be wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com