Preparation method and use of moringa oleifera leaf polysaccharides

A technology of moringa leaf and moringa leaf powder, which is applied in the direction of medical preparations containing active ingredients, pharmaceutical formulas, organic active ingredients, etc., can solve the problems of long extraction time and low extraction rate, and achieve short extraction time and high extraction efficiency. The effect of high extraction rate and low extraction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

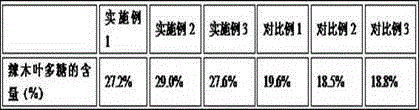

Embodiment 1

[0034] Embodiment 1, Preparation of Moringa Leaf Polysaccharide

[0035] (1) Material preparation: Weigh 1 kg of Moringa leaves, dry them at 50°C for 2 hours, crush them, and pass through a 40-mesh sieve to obtain Moringa leaves powder;

[0036] (2) Extraction: Take the Moringa oleifera leaf powder obtained in step (1), add distilled water 20 times the volume of the Moringa oleifera leaf powder, treat it under a microwave with a power of 500W for 6 minutes, and place it in a warm water bath at 45°C with an ultrasonic wave with a power of 300W. Extract 2 times, each treatment for 30 minutes, filter, combine the filtrate, concentrate the filtrate to 1 / 3 of the original volume under reduced pressure, centrifuge at 14 ° C for 10 min in a centrifuge with a rotation speed of 10,000 r / min, and take the supernatant, Concentrate the supernatant to 1 / 4 of the original volume to obtain a concentrate;

[0037](3) Deproteinization: add 2mol / L hydrochloric acid to the concentrated soluti...

Embodiment 2

[0040] Embodiment 2, Preparation of Moringa Leaf Polysaccharide

[0041] (1) Material preparation: weigh 1 kg of Moringa oleifera leaves, dry at 50°C for 2.5 h, crush them, and pass through a 45-mesh sieve to obtain Moringa oleifera leaf powder;

[0042] (2) Extraction: Take the Moringa oleifera leaf powder obtained in step (1), add distilled water 25 times the volume of the Moringa oleifera leaf powder, process it under a microwave with a power of 500W for 7 minutes, and place it in a warm water bath at 50°C with an ultrasonic wave with a power of 300W. Extract 2 times, each treatment for 35 minutes, filter, combine the filtrate, concentrate the filtrate to 1 / 3 of the original volume under reduced pressure, centrifuge at 14°C for 10 min in a centrifuge with a rotation speed of 10000 r / min, and take the supernatant, Concentrate the supernatant to 1 / 4 of the original volume to obtain a concentrate;

[0043] (3) Deproteinization: add 2mol / L hydrochloric acid to the concentrat...

Embodiment 3

[0046] Embodiment 3, Preparation of Moringa Leaf Polysaccharide

[0047] (1) Material preparation: weigh 1 kg of Moringa oleifera leaves, dry at 50°C for 3 h, pulverize, and pass through a 50-mesh sieve to obtain Moringa oleifera leaf powder;

[0048] (2) Extraction: Take the Moringa oleifera leaf powder obtained in step (1), add distilled water 25 times the volume of the Moringa oleifera leaf powder, treat it under a microwave with a power of 500W for 8 minutes, and place it in a warm water bath at 55°C with an ultrasonic wave with a power of 300W. Extract 3 times, each treatment for 40 min, filter, combine the filtrate, concentrate the filtrate to 1 / 3 of the original volume under reduced pressure, centrifuge at 14°C for 10 min in a centrifuge with a rotation speed of 10000 r / min, and take the supernatant, Concentrate the supernatant to 1 / 4 of the original volume to obtain a concentrate;

[0049] (3) Deproteinization: add 2mol / L hydrochloric acid to the concentrated soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com