Dissoluble polymeric microsphere deep profile modifying and flooding agent and preparation method thereof

A technology for adjusting the displacement agent and polymer, which is applied in the field of deep displacement adjusting agent for decomposable polymer microspheres, can solve the problems of limited promotion and use, harsh application conditions, poor temperature and salt resistance, and achieves simple construction process and initial performance. Low viscosity, easy injection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1: Weigh 42g white oil, 6.5g Span80, 1g OP-10, 0.8g decomposable cross-linking agent polyethylene glycol diacrylate (200) and mix them evenly, put them in a beaker as the oil phase, and weigh 25g Deionized water, 20g acrylamide (AM), 5g 2-acrylamide-2-methylpropanesulfonic acid (AMPS) are placed in a beaker as the water phase, and after completely dissolving, adjust the pH of the system with a mass fraction of 20% NaOH solution to 7-8. Mix the above-mentioned water phase and oil phase, stir with a high-shear emulsifier at a speed of 10,000r / min for 30 minutes to obtain a water-in-oil dispersion system, transfer the above-mentioned dispersion system into a three-necked flask, and pass nitrogen gas for 1 hour at the same time, add trigger Add 0.04g of V-50, and react for 3 hours at 300r / min to obtain a milky white emulsion product. If a solid powder product is required, take an appropriate amount of the product and centrifuge it with acetone / ethanol (volume ratio...

Embodiment 2

[0018] Example 2: Prepare a decomposable polymer microsphere dispersion system with a mass fraction of 0.3% with tap water, age in a 90°C thermostat, take the dispersion samples after aging for 0d, 1d, 3d, and 10d respectively, and observe under a polarizing microscope its morphology and structure, and measure the viscosity of the system. The results are shown in Table 1.

[0019] Table 1 Decomposition process of decomposable polymer microsphere deep control agent

[0020] Aging days (d)

0

1

3

7

Average particle size of microspheres (μm)

12.3

38.6

completely decomposed

Viscosity (mPa·s)

2.5

3.3

15.4

27.8

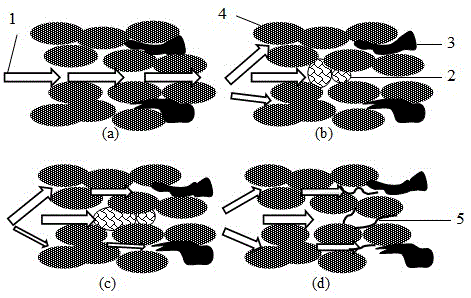

[0021] From Table 1, observed under a microscope, the initial state of the microspheres is a spherical structure, the average particle size is 12.3 microns, and the viscosity is equivalent to water. It can be seen that the microspheres have a small size and are easy to injec...

Embodiment 3

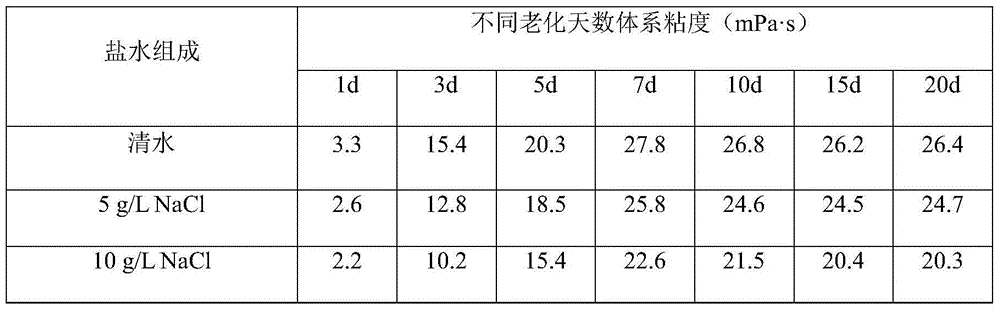

[0023] Example 3: Prepare a decomposable polymer microsphere dispersion system with a mass fraction of 0.3% with clear water, add different amounts of NaCl (0g / L, 5g / L NaCl, 10g / L NaCl), and age at 90°C for different days , take it out, and measure the viscosity of the aqueous dispersion system of the decomposable polymer microsphere deep control and drive agent for different aging days. The results are shown in Table 2.

[0024] Table 2 Effect of salinity on the decomposition performance of decomposable polymer microspheres

[0025]

[0026] It can be seen from Table 2 that after aging for 1 day, the viscosity of the aqueous dispersion system of the decomposable polymer microsphere deep control and flooding agent is low, which is basically equivalent to water, which shows that it has good injectability. You can enter the deep ground. With the increase of the aging days, the viscosity of the system showed an upward trend, and reached the maximum at about 7 days, reaching ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com