Methionine segmented copolymer, preparation method of methionine segmented copolymer and hydrogel

A technology of block copolymer and methionine, applied in the field of polyamino acid, can solve problems such as lack of pertinence, and achieve the effects of simple preparation method, simple and easy-to-obtain raw materials, and responsive release.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The present invention provides a method for preparing a methionine block copolymer described in the above technical scheme, comprising the following steps:

[0055] polymerizing the polymer and L-methionine-N-carboxylic acid internal anhydride to obtain a methionine block copolymer;

[0056] The polymer has a structure of formula IV or a structure of formula V:

[0057]

[0058] In the present invention, the polymer has a structure of formula IV or a structure of formula V:

[0059]

[0060] In formula IV, the m is the degree of polymerization, 10≤m≤227. In a specific embodiment of the present invention, the molecular weight of the polymer having the structure of formula IV is 2000 g / mol, 750 g / mol, 5000 g / mol or 10000 g / mol.

[0061]In Formula V, the n is the degree of polymerization, 10≤n≤226. In a specific embodiment of the present invention, the molecular weight of the polymer having the structure of formula V is 2000 g / mol, 750 g / mol, 5000 g / mol or 10000 g...

Embodiment 1

[0107] Dissolve 10g of polyethylene glycol monomethyl ether with a number average molecular weight of 750 and toluene in 100mL of dry dichloromethane, add 9.3mL of triethylamine and 20.6mL of methanesulfonyl chloride to the solution, and react for 72 hours Afterwards, the reaction solution was concentrated, settled with ether, filtered, washed, and dried to obtain polyethylene glycol monomethyl ether methanesulfonate. Dissolve the obtained methylsulfonic acid polyethylene glycol monomethyl ether and an equal amount of ammonium chloride in 300 mL of ammonia water for ammonolysis reaction. After reacting for 72 hours, extract the reaction solution with dichloromethane and wash with saturated sodium chloride solution. , after drying, settle with ether, filter, and dry to obtain end-aminated polyethylene glycol monomethyl ether with a molecular weight of 750.

[0108] Azeotrope 1.5 g of aminated polyethylene glycol monomethyl ether with a number average molecular weight of 750 and...

Embodiment 2

[0111] Dissolve 10g of polyethylene glycol monomethyl ether with a number average molecular weight of 2000 and toluene in 100mL of dry dichloromethane, add 3.5mL of triethylamine and 7.7mL of methylsulfonyl chloride to the solution, and react for 72 hours Afterwards, the reaction solution was concentrated, settled with ether, filtered, washed, and dried to obtain polyethylene glycol monomethyl ether methanesulfonate. Dissolve the obtained methylsulfonic acid polyethylene glycol monomethyl ether and an equal amount of ammonium chloride in 300 mL of ammonia water for ammonolysis reaction. After reacting for 72 hours, extract the reaction solution with dichloromethane and wash with saturated sodium chloride solution. , after drying, settle with ether, filter, and dry to obtain end-aminated polyethylene glycol monomethyl ether with a molecular weight of 2,000.

[0112] Azeotrope 2g of aminated polyethylene glycol monomethyl ether with a number average molecular weight of 2000 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ionic strength | aaaaa | aaaaa |

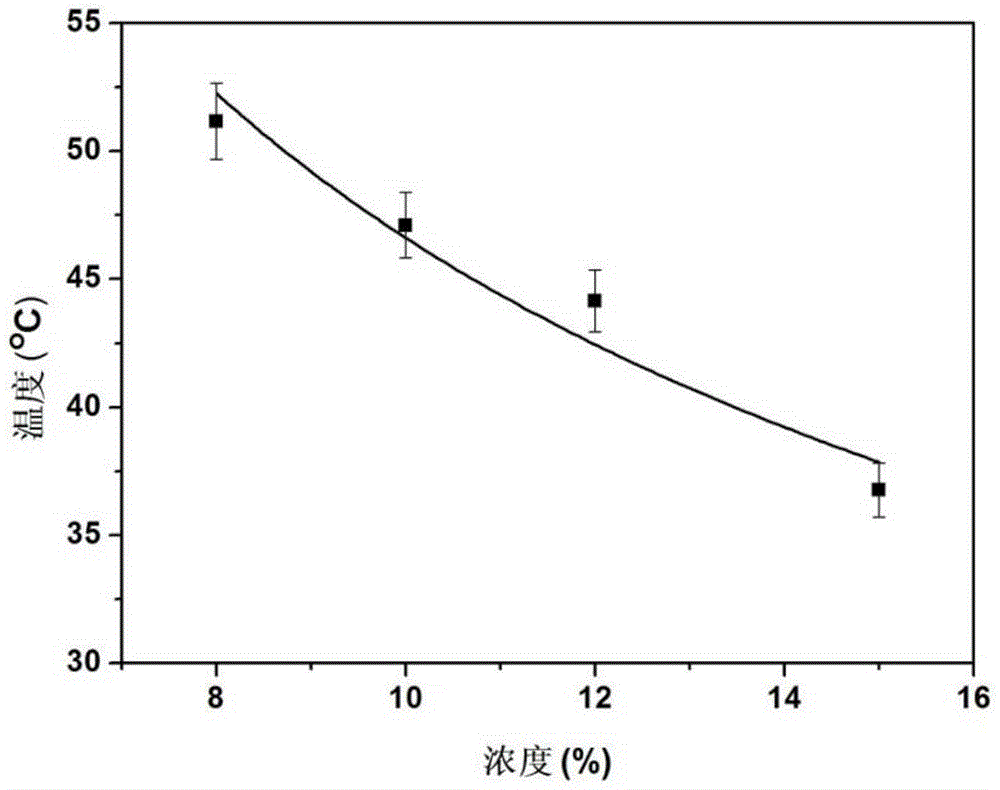

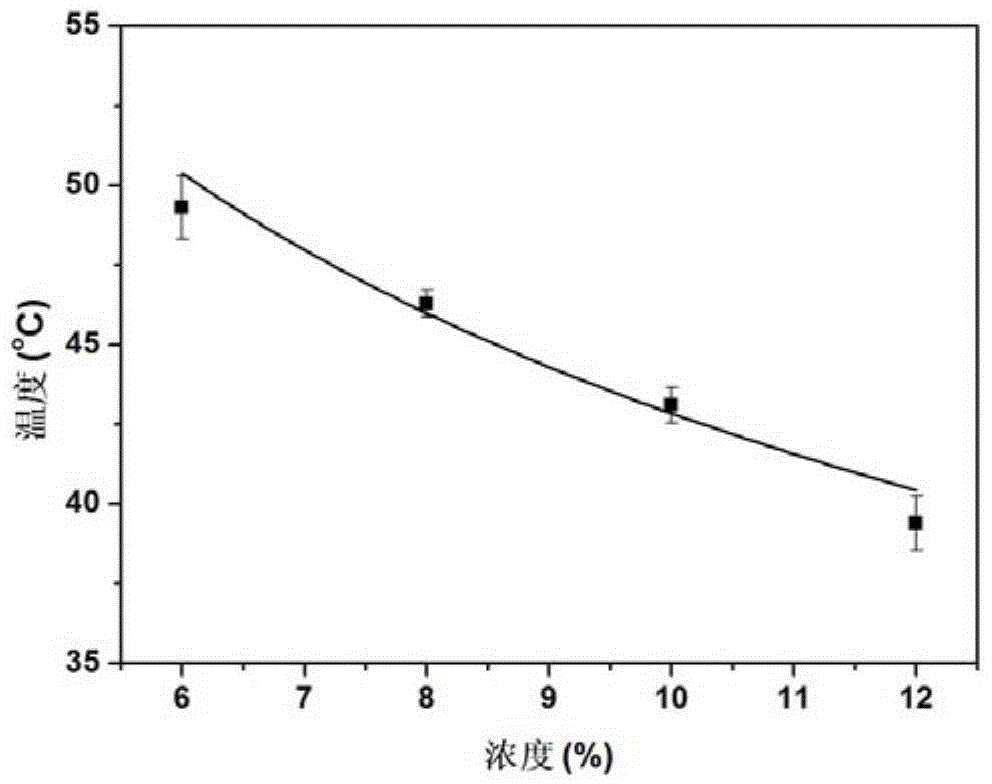

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com