UV (ultraviolet) offset printing gloss oil and preparation method thereof

A printing and ultraviolet light technology, which is applied to biocide-containing paints, coatings, antifouling/underwater coatings, etc., can solve the problems of poor scratch resistance, poor surface flatness of printed products, and easy breeding of bacteria on the surface of printed products, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

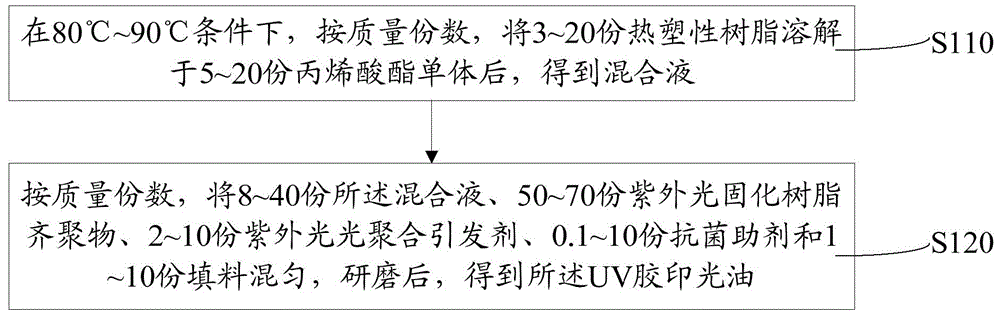

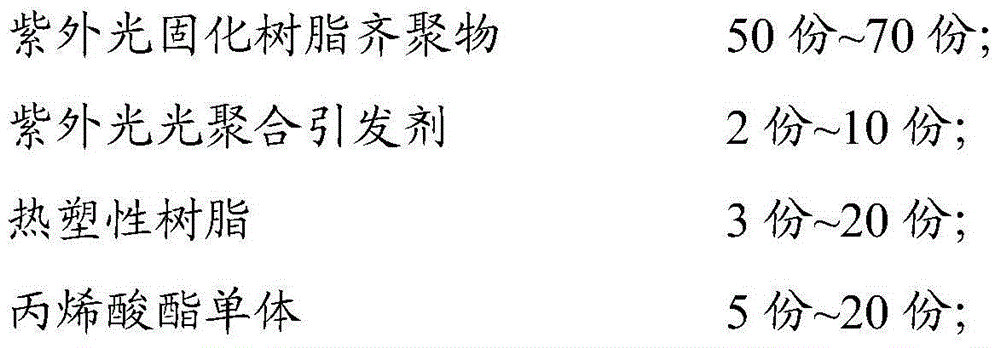

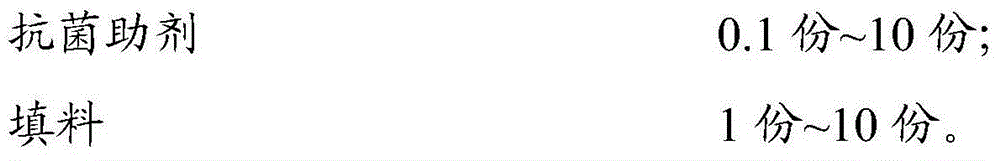

[0048] Such as figure 1 The preparation method of the UV offset printing varnish of one embodiment shown, comprises the steps:

[0049] S110, under the condition of 80° C. to 90° C., according to parts by mass, 3 to 20 parts of thermoplastic resin are dissolved in 5 to 20 parts of acrylate monomer to obtain a mixed solution.

[0050] At normal temperature, the viscosity of thermoplastic resin is relatively high, and it is viscous liquid or solid. By using acrylate monomer with low viscosity in advance and under the condition of 80 ° C to 90 ° C, the thermoplastic resin can be dissolved in the acrylate monomer. , so that it can be better mixed with other components, and then the final grinding operation of UV offset varnish semi-finished products can be better carried out.

[0051] S120, in parts by mass, 8 to 40 parts of the mixed solution, 50 to 70 parts of UV curable resin oligomer, 2 to 10 parts of UV photopolymerization initiator, 0.1 to 10 parts of antibacterial auxiliar...

Embodiment 1

[0061] Take 20Kg of trimethylolpropane triacrylate, add it to the reaction vessel, add 3Kg of diallyl phthalate polymer while stirring at a speed of 200rpm / min, and the temperature rises to 85±5°C until The material reacts to a transparent viscous liquid, cools down and discharges the material, pours it into the production container, and then adds 35Kg of urethane acrylate with 2 average functionalities and 30Kg of urethane acrylate with 6 average functionalities to the production container, and disperses at 300rpm / min speed, while stirring, add 4Kg of photopolymerization initiator 1-hydroxyl-cyclohexyl-phenyl ketone and 4Kg of 2,4,6 (trimethylbenzoyl) diphenylphosphine oxide, 0.1Kg of As the polymerization agent p-hydroxyanisole, adjust the dispersion speed of the disperser to 1800rpm / min, fully dissolve the initiator and polymerization inhibitor, add 1Kg of micronized polyethylene wax, 1Kg of talcum powder, and 1Kg of nano-scale antibacterial Auxiliary magnesium oxide, 0.5Kg...

Embodiment 2

[0063]Take 20Kg of propoxylated glycerin triacrylate, add it to the reaction vessel, and add 10Kg of polyketone resin while stirring at a speed of 200rpm / min, and the temperature rises to 85±5°C until the material reacts to a transparent viscous liquid. Cool down and discharge the material, pour it into the production container, and then add 29Kg of amine-modified epoxy acrylate with 2 average functionalities and 30Kg of 4 average functional polyester acrylate to the production container, with a dispersion speed of 300rpm / min, while Add 4Kg of photopolymerization initiator 1-hydroxyl-cyclohexyl-phenyl ketone and 4Kg of 2-methyl-1-[4-methylthiophenyl]-2-morpholino-1-acetone while stirring , 0.1Kg of polymerization inhibitor p-hydroxyanisole, adjust the dispersion speed of the disperser to 1800rpm / min, after fully dissolving the initiator and polymerization inhibitor, add 1Kg of superfine polytetrafluoroethylene wax, 0.5Kg of Fumed silica, 0.5Kg of nano-scale antibacterial addit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com