Water-based emulsion composite blocking remover

A composite plugging removal agent and technology of plugging removal agent, which is applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problem of affecting the injection capacity of water injection wells and oil well productivity, the poor effect of organic plugging and plugging removal, and the ability to dissolve organic scale Weakness and other problems, to achieve good reservoir stimulation characteristics, low corrosion, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

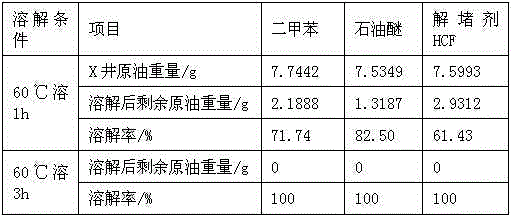

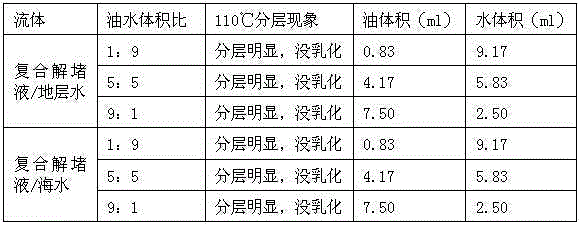

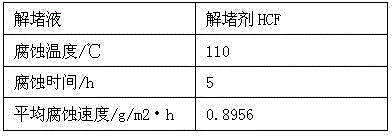

Examples

Embodiment Construction

[0017] The water-based emulsion composite plug-removing agent is formed by mixing an inorganic plug-removing agent and an organic plug-removing agent according to the ratio of parts by mass of 4-6:1.

[0018] The organic plug-removing agent is a mixture of monoalkyl esters of complex long-chain fatty acids and polyol organic polyether esters; wherein the monoalkyl esters of fatty acids are fatty acid monoalkyl esters obtained by reacting C16-C18 fatty acids with methanol; Ether polyol is formed by polymerizing organic dicarboxylic acid and ethylene glycol; its mass-to-number ratio is fatty acid monoalkyl ester:polyether polyol=5~10:1.

[0019] The inorganic plugging agent consists of the following raw materials in parts by mass:

[0020]

[0021] The organic acid is a mixture of methanesulfonic acid, sulfamic acid and chloroacetic acid, and its mass-number ratio is methanesulfonic acid:sulfamic acid:chloroacetic acid=0.5~1:0.5~1:1~1.5.

[0022] The scale conversion agent i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com