Active catalytic viscosity reducer for viscous oil recovery, and preparation method and application thereof

A technology for catalytic viscosity reduction and catalyst, applied in chemical instruments and methods, preparation of organic compounds, preparation of ethers, etc., can solve problems such as poor viscosity reduction effect of viscosity reducers, and achieve good viscosity reduction effect and improved viscosity reduction rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

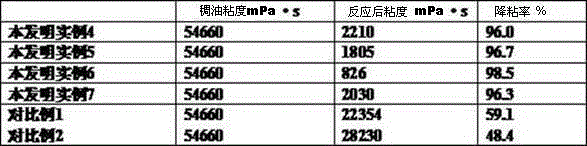

Examples

Embodiment 1

[0017] Embodiment 1, the active type catalytic viscosity reducer is used for the development of heavy oil, and the general structural formula is: [R-O-(EO) m CH 2 CO 2 ] 2 M, wherein, R is a linear or branched alkyl group with 12 to 18 carbon atoms, EO is an oxyethylene group, m is the number of oxyethylene, and m is an integer between 2 and 6; M is a nickel ion or a manganese ion Or copper ions or zinc ions.

Embodiment 2

[0018] Example 2, the heavy oil is obtained by the following preparation method using an active catalytic viscosity reducer: in the first step, add a long-chain fatty alcohol and a catalyst in the reactor and mix evenly, and the catalyst is 0.3 to Add in 1% amount, after adding long-chain fatty alcohol and catalyst, N 2 Purge the reactor to replace the air and evacuate it. Under an absolute pressure of 5kPa to 30kPa, add 2mol to 6mol of ethylene oxide to 1mol of long-chain fatty alcohol, and feed ethylene oxide into the reactor and mix well. Stir the reaction at a temperature of 120°C to 140°C for 4h to 8h, and the fatty alcohol ether is obtained after the reaction; in the second step, based on 0.1moL of fatty alcohol ether, take 0.1moL of fatty alcohol ether and put it in a container, add 20mL to 40mL of iso Propanol or absolute ethanol, 0.20moL to 0.26moL sodium hydroxide stirred reaction for 0.5h to 3h, 0.1moL to 0.13moL chloroacetic acid was made into a chloroacetic aci...

Embodiment 3

[0019] Example 3, the heavy oil is obtained by the following preparation method using an active catalytic viscosity reducer: in the first step, add a long-chain fatty alcohol and a catalyst in the reactor and mix evenly, and the catalyst is 0.3 or Add in 1% amount, after adding long-chain fatty alcohol and catalyst, N 2 Purge the reactor to replace the air and evacuate it. Under the absolute pressure of 5kPa or 30kPa, add 2mol or 6moL of ethylene oxide to 1mol of long-chain fatty alcohol, feed ethylene oxide into the reactor and mix evenly. Stir the reaction at 120°C or 140°C for 4h or 8h, and obtain fatty alcohol ether after the reaction; in the second step, take 0.1moL fatty alcohol ether into the container, add 20mL or 40mL iso Propanol or absolute ethanol, 0.20moL or 0.26moL sodium hydroxide stirred reaction for 0.5h or 3h, 0.1moL or 0.13moL chloroacetic acid was made into a 20% or 50% mass percentage of chloroacetic acid aqueous solution, after stirring the reaction, add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com