Detection method of hot shear cutter material laser shock residual stress thermal relaxation

A technology of residual stress and laser shock, which is applied in the detection and analysis of material processing, and in the field of mechanical manufacturing, can solve the problem of affecting structural fatigue strength, brittle fracture resistance, stress corrosion cracking and high temperature creep cracking, reducing structural stiffness and stability In order to achieve the effect of low cost, easy operation and high detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

[0029] A method for detecting thermal relaxation of thermal scissors material laser shock residual stress, comprising the following steps:

[0030] (1) Establish the finite element model of the hot shear tool material:

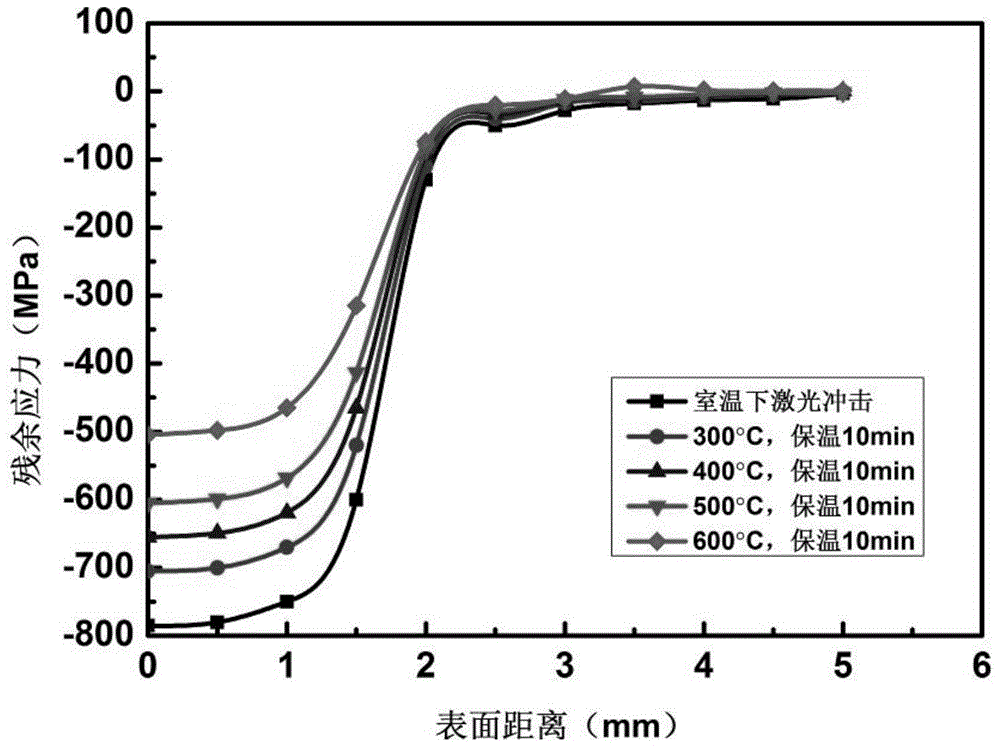

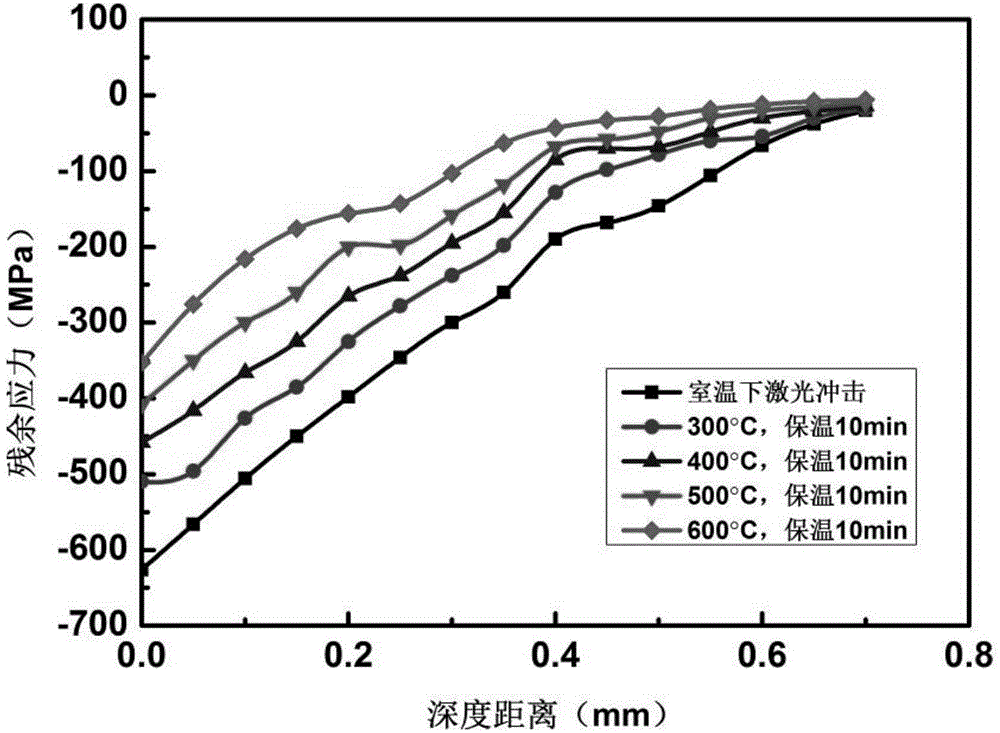

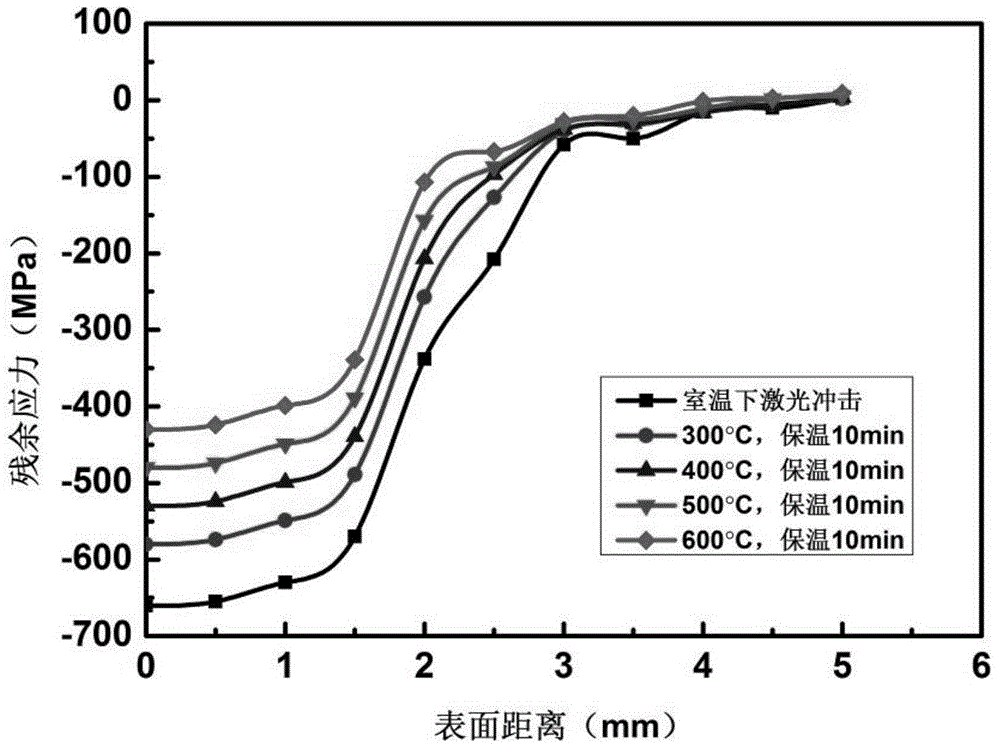

[0031] Cut the hot shear tool material 6CrW2Si steel into rectangular pieces with length, width and height of 10cm, 10cm and 5cm respectively, and use the Y axis as the central axis of symmetry in the simulation software ANSYS / LS_DYNA, and the X-Z plane as the laser shock plane Create its geometric model; the element selection is 8-node hexahedral element SOLID164; the mesh division process is to refine the mesh in the area of 2 times the length of the spot radius on the three coordinate axes, and use sparse mesh for the rest; select the JC model as the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com