Feed mould inhibitor and preparation method thereof

A technology of antifungal agent and feed, applied in animal feed, animal feed, application, etc., can solve the problems of narrow antibacterial spectrum and unsatisfactory antibacterial effect, so as to extend the shelf life, improve the comprehensiveness of nutrition, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

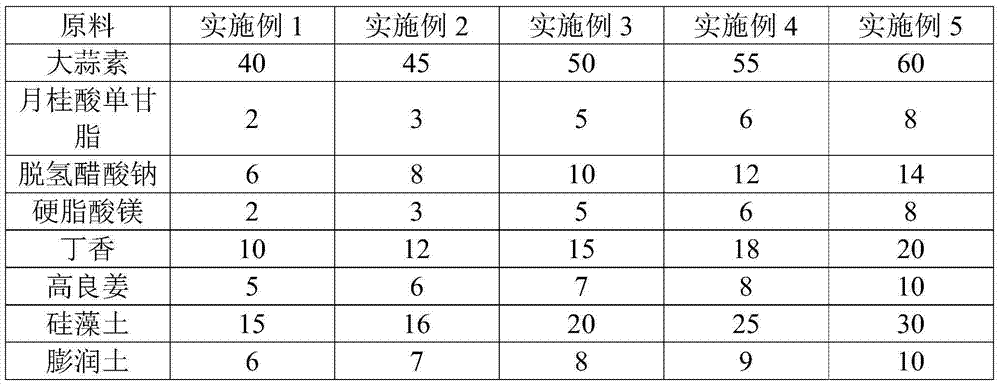

Examples

Embodiment 3

[0021] Embodiment 3 is a preferred embodiment.

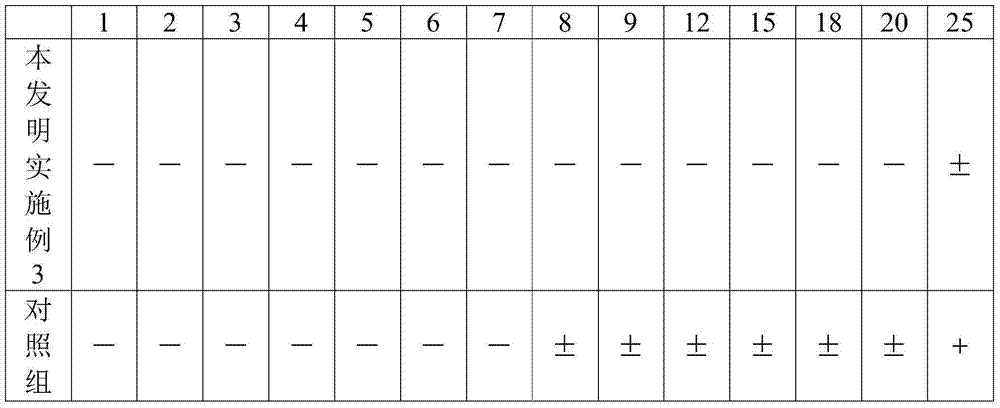

[0022] Anti-mildew performance test:

[0023] 1. Feed preparation: 50g corn, 30g bran, 20g soybean meal, 10g cotton meal, 10g stone powder, 0.02g methionine, 0.02g lysine, and 0.5g vitamin. Add commercially available anti-mold agent and anti-mold agent of the present invention respectively in the feed, the addition amount is 2%; Granulate according to conventional method.

[0024] 2. Carry out follow-up testing on the control group and the experimental group respectively. The summer testing results are shown in Table 2.

[0025]

[0026]

[0027] Note: "-" no hyphae, no mildew;

[0028] "±" has slight hyphae and no mildew;

[0029] "+" severe mildew;

[0030] In spring and autumn, the shelf life of feed can reach more than 40 days, and in winter, the shelf life of feed can reach more than 120 days.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com