Reticular porous heavy metal adsorption material loaded with nano-iron oxide and preparation method thereof

A nano-iron oxide and mesh-like porous technology, applied in chemical instruments and methods, alkali metal compounds, adsorbed water/sewage treatment, etc., can solve problems such as poor adaptability of wastewater, difficulty in achieving results, and time-consuming bacteria breeding , to achieve the effect of improving adsorption effect, improving efficiency and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

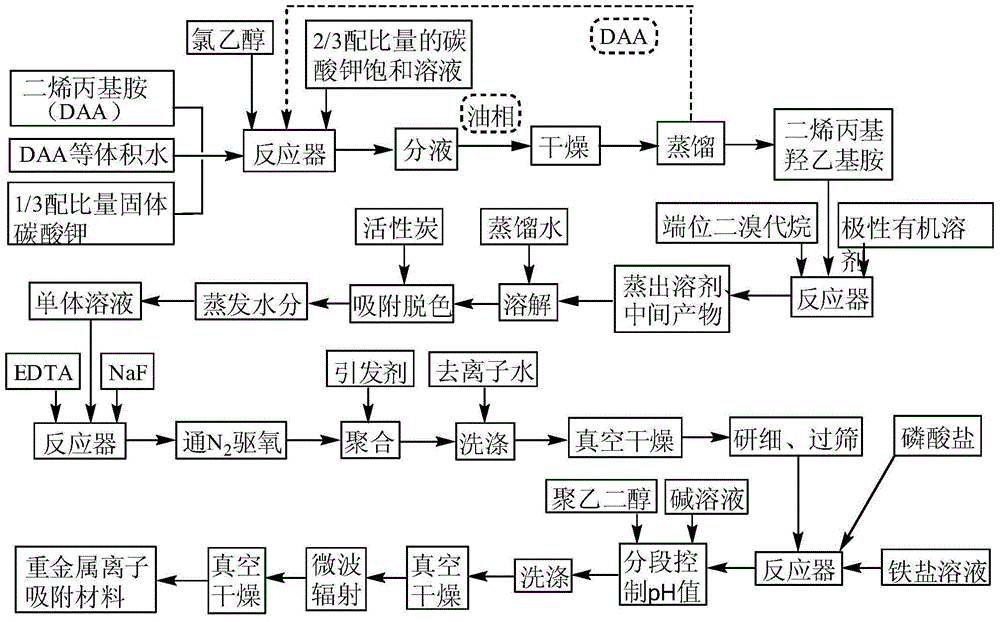

Method used

Image

Examples

Embodiment 1

[0037] (1) Mix diallylamine, chlorohydrin and potassium carbonate in a molar ratio of 1.5:1.0:1.0, first add 68.9mL of diallylamine and 68.9mL of water to a 500mL dripping solution with a condenser tube and constant pressure Add 16.92g of solid potassium carbonate to the funnel and mechanically stirred reactor, raise the temperature to 60°C, slowly add 25mL of chloroethanol dropwise, and finish dropping within 3 hours, then add 64.87g of potassium carbonate saturated solution dropwise, finish adding within 2 hours, continue React for 2 hours; transfer to a separatory funnel, let stand for 30 minutes, separate the liquids, dry the oil phase with anhydrous potassium carbonate, distill 19.7 mL of unreacted diallylamine into the next round of reaction; distill under reduced pressure to - 0.093MPa, collect 42.3mL of distillate at 117~121℃, which is the intermediate product diallyl hydroxyethylamine, the yield is 76.82%;

[0038] (2) Step (1) intermediate product diallyl hydroxyethy...

Embodiment 2

[0049] (1) Mix diallylamine, chloroethanol and potassium carbonate in a molar ratio of 2.0:1.0:1.02, first add 91.8mL of diallylamine and 91.8mL of water to a 500mL dripping solution with a condenser tube and constant pressure Add 17.25g of solid potassium carbonate to the funnel and mechanically stirred reactor, raise the temperature to 70°C, slowly add 25mL of chloroethanol dropwise, and finish dropping within 3 hours, then add 66.17g of saturated potassium carbonate solution dropwise, finish adding within 2 hours, continue React for 1.5h; transfer to a separatory funnel, let stand for 30min, separate the liquids, dry the oil phase with anhydrous potassium carbonate, distill 43.1mL of unreacted diallylamine into the next round of reaction; distill under reduced pressure to -0.093MPa, collect 45.5mL of distillate at 117~121℃, which is the intermediate product diallyl hydroxyethylamine, the yield is 78.95%;

[0050] (2) The intermediate product diallyl hydroxyethylamine obtain...

Embodiment 3

[0056] (1) Mix diallylamine, chloroethanol and potassium carbonate in a molar ratio of 2.5:1.0:1.05, first add 114.8mL of diallylamine and 114.8mL of water to a 500mL dripping solution with a condenser tube and constant pressure Add 17.76g of solid potassium carbonate to the funnel and mechanically stirred reactor, raise the temperature to 75°C, slowly add 25mL of chloroethanol dropwise, and finish dropping within 3 hours, then add 68.12g of potassium carbonate saturated solution dropwise, finish adding within 2 hours, continue React for 1 hour; transfer to a separatory funnel, let stand for 30 minutes, separate the liquids, dry the oil phase with anhydrous potassium carbonate, distill out 64.2 mL of unreacted diallylamine and enter the next round of reaction; distill under reduced pressure to - 0.093MPa, collect 46.2mL of distillate at 117~121℃, which is the intermediate product diallyl hydroxyethylamine, the yield is 80.12%;

[0057] (2) Step (1) obtained intermediate produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com