System and technology for producing benzaldehyde by utilizing benzyl chloride and benzyl alcohol waste materials

A technology of benzyl alcohol and benzaldehyde, applied in the field of benzaldehyde production, to achieve the effect of solving environmental protection problems, simple process and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

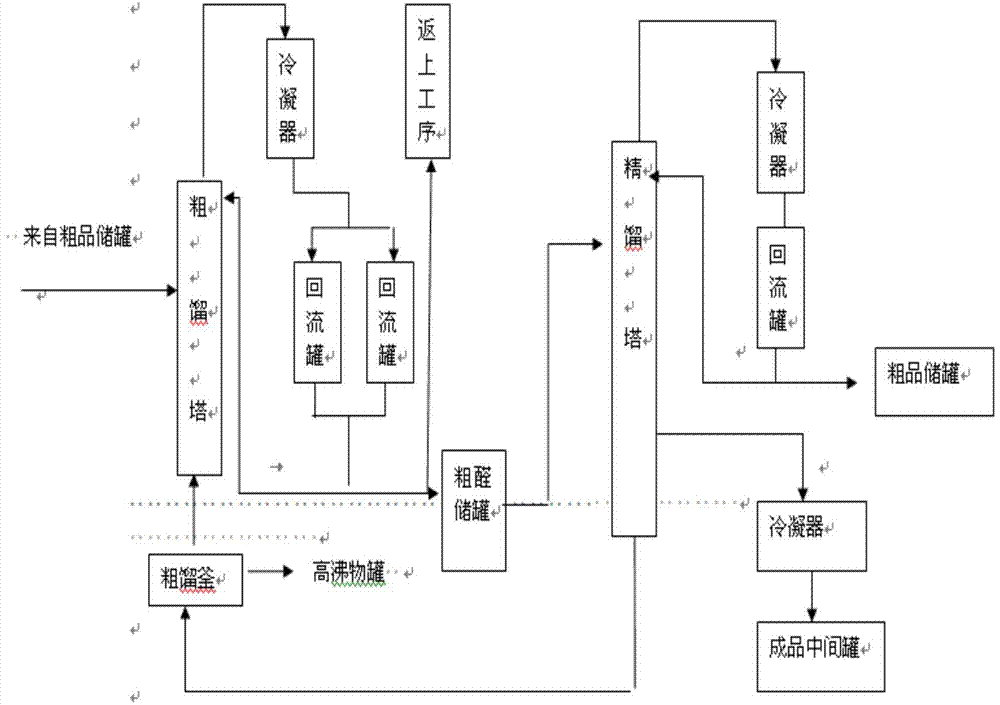

[0028] A device for producing benzaldehyde by using benzyl chloride and benzyl alcohol waste, including main equipments of oxidation furnace, oxidation kettle, hydrolysis kettle, alkaline hydrolysis kettle, crude distillation tower, crude distillation kettle and rectification tower.

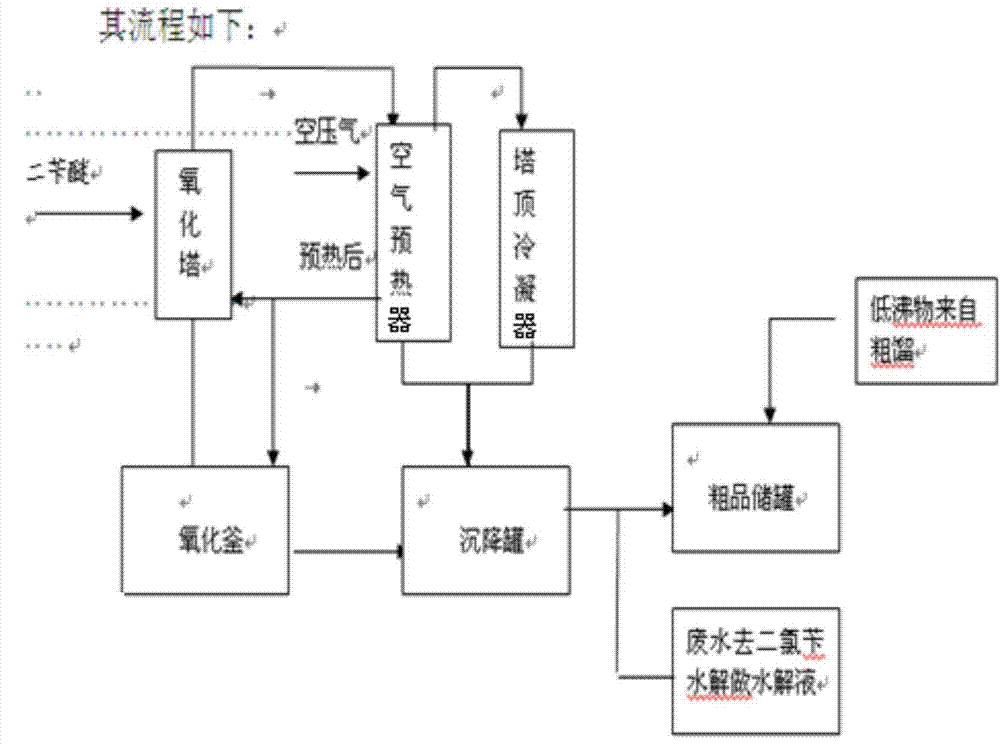

[0029] The process flow is as follows: the raw material dibenzyl ether is transported to the oxidation tower, transfers mass and heat with the rising gas in the oxidation tank, enters the main oxidation tank, and reacts with oxygen in the compressed air in the main oxidation tank to form benzaldehyde, and the reaction product Enter the settling tank for oil-water separation, and the crude product containing benzaldehyde ≥ 80% is obtained and sent to the crude product storage tank for standby.

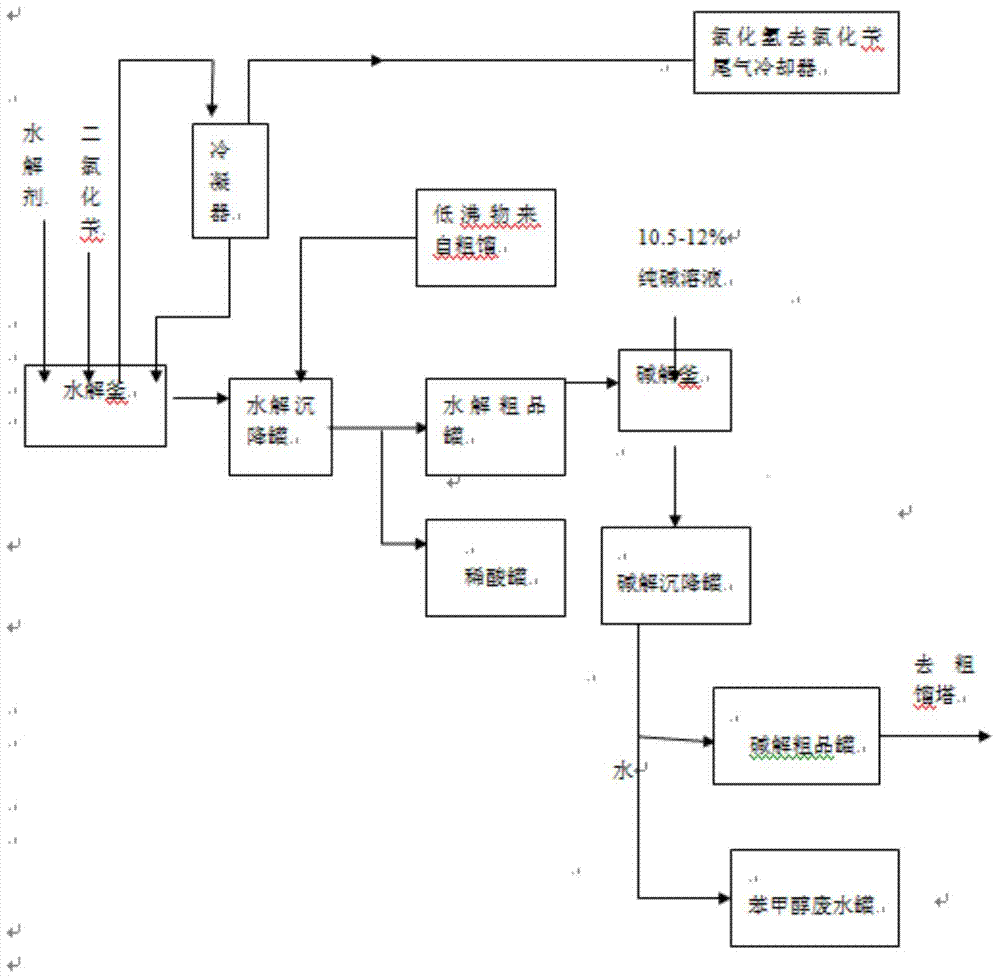

[0030] The hydrolyzate and benzyl dichloride are continuously added to the hydrolysis kettle, and the temperature is raised by low-pressure steam, and a hydrolysis reaction occurs in the hydrolysis kettle. ...

Embodiment 2

[0033] A system for producing benzaldehyde by utilizing benzyl chloride and benzyl alcohol waste, comprising a dibenzyl ether oxidation unit, a benzyl dichloride treatment unit, and a multistage rectification unit,

[0034] The dibenzyl ether oxidation device comprises an oxidation tower, an oxidation still, a settling tank, and a crude product storage tank, and the oxidation tower, an oxidation still, a settling tank, and a crude product storage tank are connected in sequence, and the top exhaust port of the oxidation tower is connected to the air preheater The second air inlet at the top is connected, the first air outlet at the bottom of the air preheater is connected with the air inlet at the bottom of the oxidation tower, the second air outlet at the bottom of the air preheater is connected with the air inlet of the oxidation kettle, and the crude product The discharge port of the storage tank is connected with the feed port of the rectification tower;

[0035] Benzyl dic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com