Carbon composite material and preparation method therefor

A technology of carbon composite materials and compounds, applied in the direction of electrical components, electrochemical generators, battery electrodes, etc., can solve unsatisfactory problems and achieve the effect of complete coating, high product quality and uniform coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

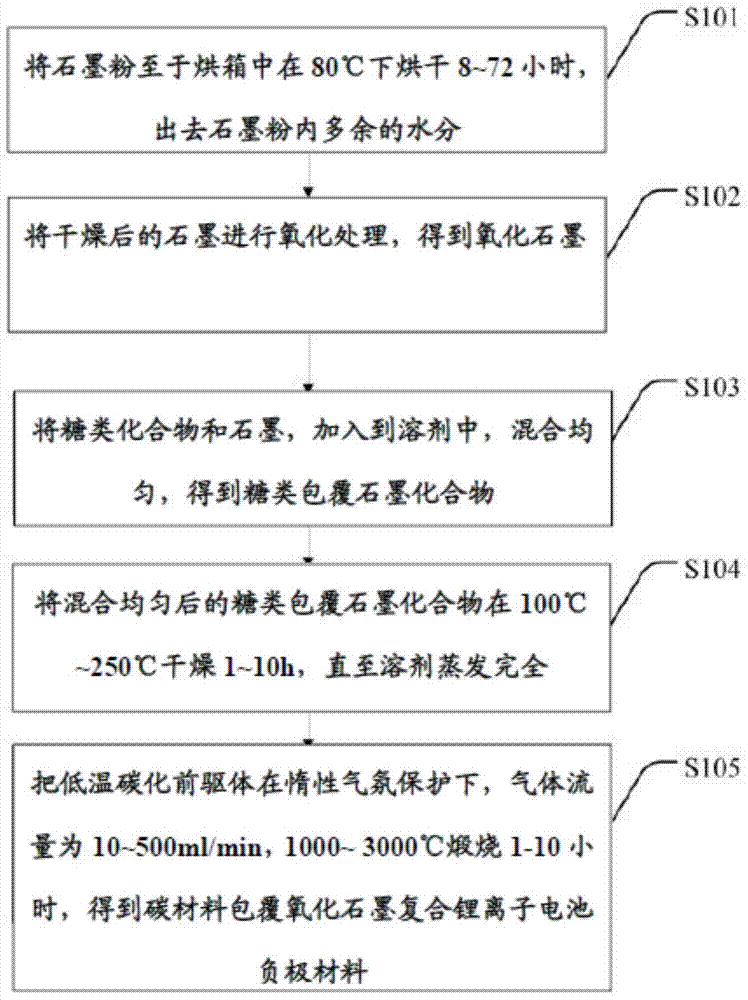

[0025] The invention provides a method for preparing a carbon composite material. The steps include: A. oxidizing graphite to obtain surface oxide graphite; B. mixing sugar compounds, surface oxide graphite and a solvent to obtain a mixture; C. mixing the mixture Treat at 100°C-250°C for 1-10 hours to obtain the precursor; D. Calcinate the precursor under air at 300-1600°C for 1-10 hours to obtain the carbon composite material. The prepared carbon composite material has uniform coating layer, smooth surface, complete coating, perfect shape, especially excellent electrochemical performance of the material, and the method is simple to operate and easy to realize.

[0026] Wherein, the graphite in step A can be pretreated graphite, and the pretreatment is various pretreatments known to those skilled in the art, for example, graphite can be dried, for example, graphite powder is placed in an oven at 80 ° C Bake for 8-72 hours to remove excess moisture in the graphite powder. Wher...

Embodiment 1

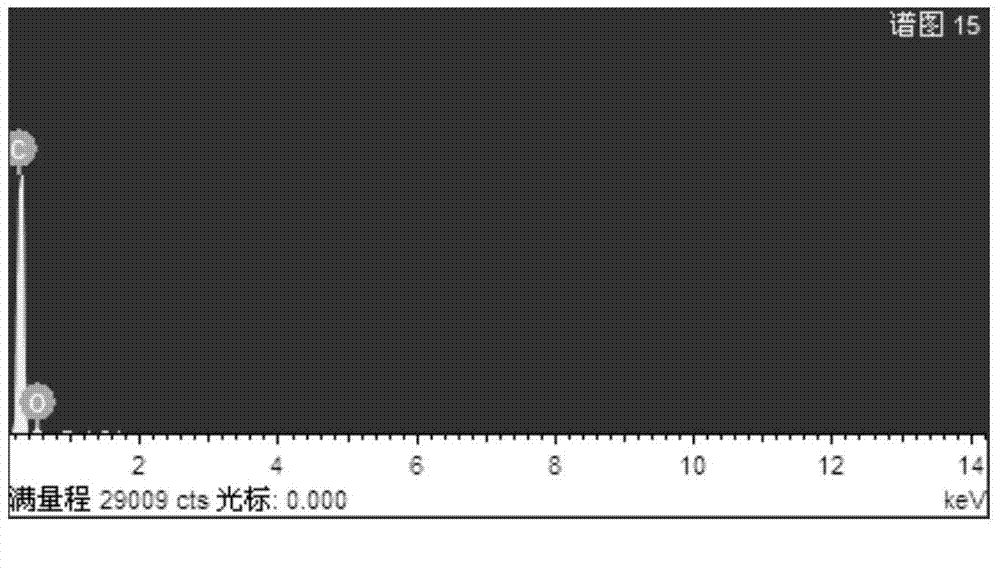

[0046] Dry 20g of graphite powder at 90°C for 24 hours to obtain dry graphite powder, take 10g of dry graphite powder and place it in a muffle furnace, keep the temperature at 350°C for 5 hours, take it out for later use after cooling to normal temperature, and obtain a gas phase Graphite oxide surface. The atomic percentage of oxygen is 6.97%, and the weight percentage of oxygen is 9.08% (obtained by the S-3400N scanning electron microscope test of Hitachi, Japan, such as figure 2 shown).

[0047] Stir 20g of glucose with 100mL of water at room temperature for 12 hours to form a uniform glucose solution, then add 7.5g of the surface graphite oxide powder prepared above, and use a planetary ball mill to grind the sample with a ball-to-material ratio of 15:1 and a speed of 400rad / min , ball milled for 10 h, and after discharge, treated in an oven at 220°C for 3 h to obtain a thermally oxidized precursor. The thermally oxidized precursor was placed in a porcelain boat, calcin...

Embodiment 2

[0052] Dry 20g of graphite powder at 90°C for 24 hours to obtain dry graphite powder, put 10g of graphite powder in a beaker, add 50mL of 30% hydrogen peroxide, stir at 80°C until completely dry, take it out Place in a vacuum oven and dry at 80° C. for 6 hours to obtain graphite oxide on the surface of the liquid phase.

[0053] Stir 20g of glucose with 100mL of water at room temperature for 12 hours to form a uniform glucose solution, then add 7.5g of the surface graphite oxide powder prepared above, and use a planetary ball mill to grind the sample with a ball-to-material ratio of 15:1 and a speed of 400rad / min , ball milled for 10 h, and after discharge, treated in an oven at 220°C for 3 h to obtain a thermally oxidized precursor. The thermally oxidized precursor was placed in a porcelain boat, calcined in an air atmosphere at a gas flow rate of 250ml / min, selected at a temperature of 350°C, and held for 6 h, and then cooled to room temperature to obtain a carbon composite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com