VOCs removing method based on photocatalytic free radical advanced oxidation

An advanced oxidation and free radical technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of small footprint, low light-off temperature, and increased operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

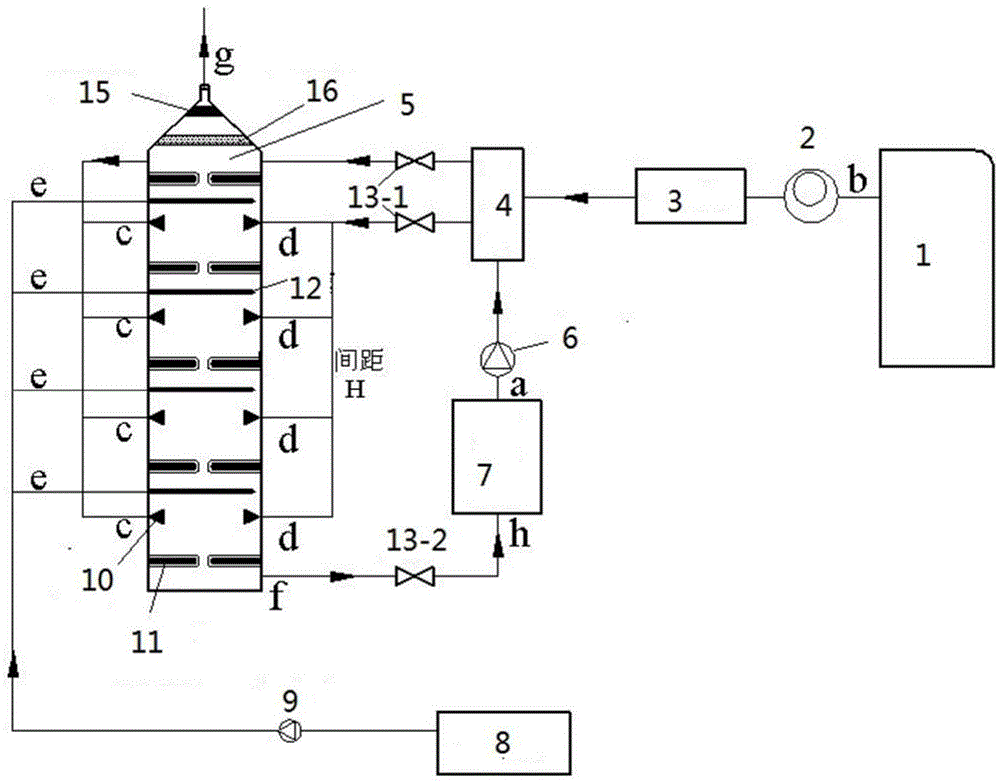

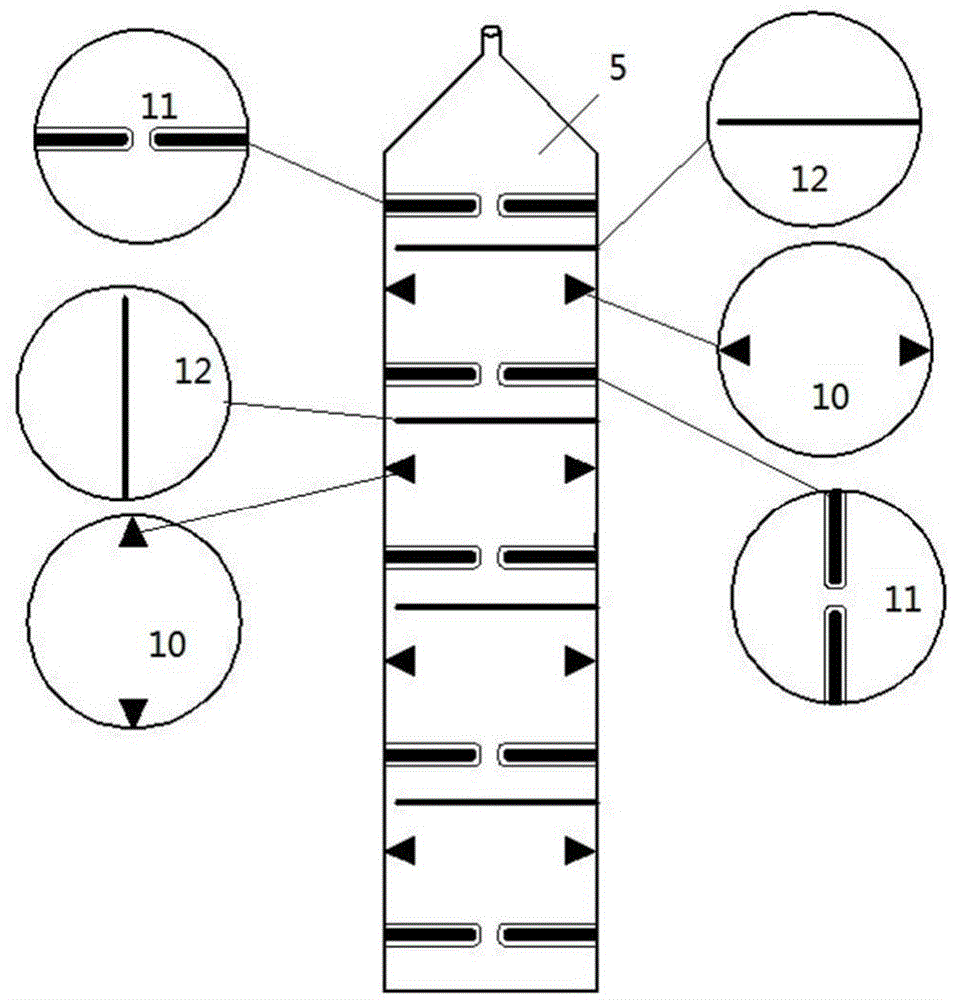

Method used

Image

Examples

Embodiment 1

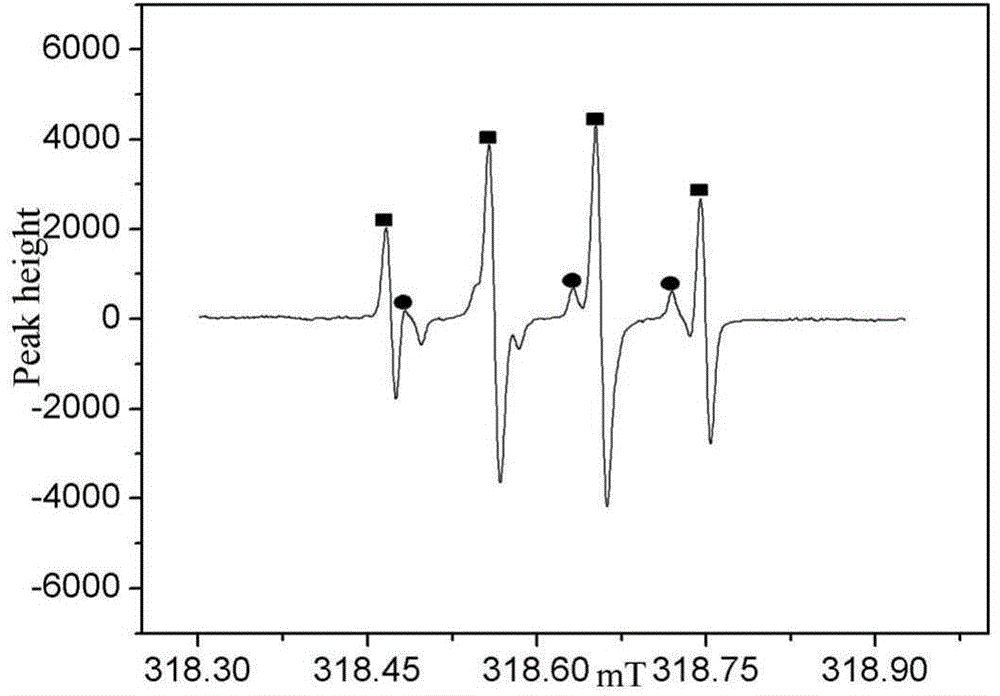

[0060] Example 1. The flue gas inlet temperature of the impingement bed is 100°C, and the liquid-gas ratio is 0.5L / m 3 , the dosage of iron oxide is 0.1kg / m 3 , the concentration of hydrogen peroxide is 0.5mol / L, the pH of the solution is 3.4, the temperature of the solution is 70°C, and the content of toluene in the flue gas is 600μg / m 3 , the effective radiation intensity of ultraviolet light is 25μW / cm 2 , The effective wavelength of ultraviolet light is 254nm. The results of the small test are: the removal efficiency reaches 59.1%.

Embodiment 2

[0061] Example 2. The flue gas inlet temperature of the impingement bed is 100°C, and the liquid-gas ratio is 0.5L / m 3 , the dosage of iron oxide is 0.1kg / m 3 , the concentration of ammonium persulfate is 0.5mol / L, the pH of the solution is 3.4, the temperature of the solution is 70°C, and the content of toluene in the flue gas is 600μg / m 3 , the effective radiation intensity of ultraviolet light is 25μW / cm 2 , The effective wavelength of ultraviolet light is 254nm. The results of the small test are: the removal efficiency reaches 54.3%.

Embodiment 3

[0062] Example 3. The flue gas inlet temperature of the impingement bed is 100°C, and the liquid-gas ratio is 0.5L / m 3 , the dosage of iron oxide is 0.1kg / m 3 , the concentration of hydrogen peroxide is 1.0mol / L, the pH of the solution is 3.4, the temperature of the solution is 70°C, and the content of toluene in the flue gas is 600μg / m 3, the effective radiation intensity of ultraviolet light is 25μW / cm 2 , The effective wavelength of ultraviolet light is 254nm. The result of the small test is: the removal efficiency reaches 79.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Removal efficiency | aaaaa | aaaaa |

| Removal efficiency | aaaaa | aaaaa |

| Removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com