Method for preparing porous titanate adsorbent through acetic acid activation on sludge

A technology of activated sludge and titanate, applied in chemical instruments and methods, sludge treatment, water/sludge/sewage treatment, etc., can solve problems such as sludge pollution, achieve environmental pollution, reduce synthesis costs, Good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

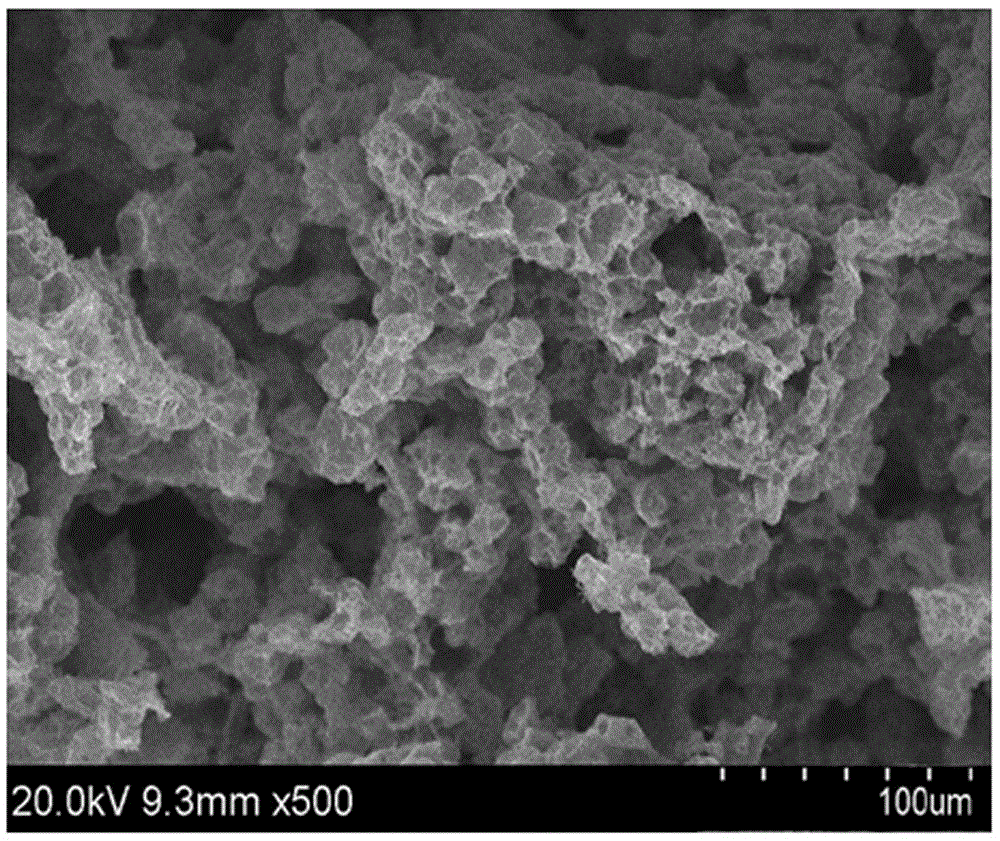

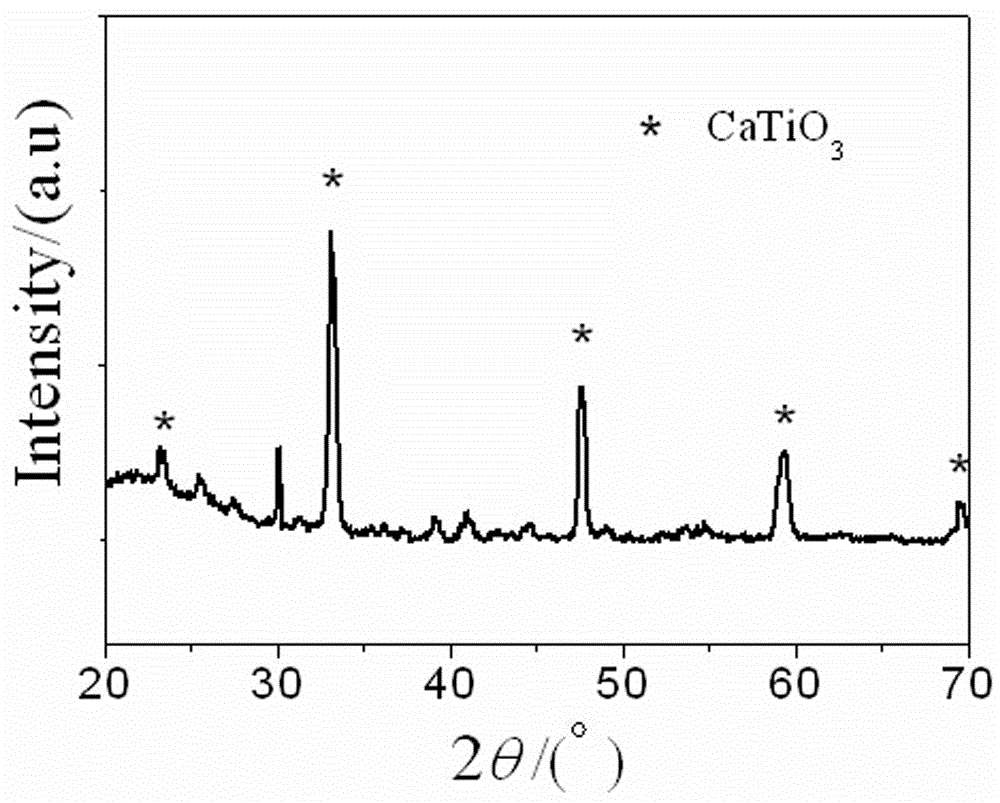

[0022] A method for preparing a porous titanate adsorbent from acetic acid activated sludge, characterized in that it comprises the following process steps:

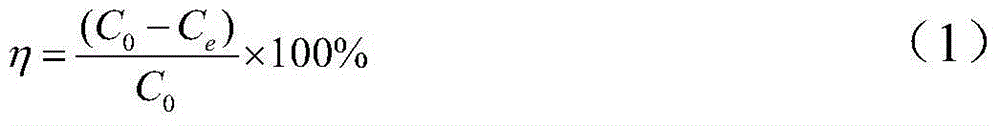

[0023] Take 1000g of sludge, adjust the moisture content to 85%, put it in a mashing homogenizer, add 800g of glacial acetic acid, mash and homogenize it for 30min at a stirring speed of 5000r / min, take it out, and put it in a 180W 40KHz ultrasonic oscillator Shake for 60 minutes, airtight, and soak at 50°C for 24 hours to obtain a homogeneous acetic acid activated sludge slurry; weigh 1000g of acetic acid activated sludge, add 800g of tetrabutyl titanate dropwise under continuous stirring conditions, add dropwise After that, continue to stir for 30 minutes, then add 238g of limestone powder, stir evenly, heat to 90°C and keep stirring for 30 minutes to react, evaporate the water and dry at 105°C to make titanium-calcium-sludge xerogel. In a box-type electric furnace, under the condition of 750 ° C, calcined in the air a...

Embodiment 2

[0026] A method for preparing a porous titanate adsorbent from acetic acid activated sludge, characterized in that it comprises the following process steps:

[0027] Take 1000g of newly discharged excess sludge, add 200mL of water, adjust the water content to 87.5%, put it in a mashing and homogenizing machine, add 700g of glacial acetic acid, and mash and homogenize it for 30min at a stirring speed of 5000r / min, take it out, put Oscillate in a 500W 40KHz ultrasonic oscillator for 60min, airtight, and soak at 60°C for 22h to obtain a homogeneous acetic acid-activated sludge slurry; weigh 1000g of acetic acid-activated sludge, and add 900g of it dropwise under continuous stirring After the addition of tetrabutyl titanate, continue to stir for 30 minutes, then add 268g of limestone powder, stir evenly, heat to 90°C, keep stirring and react for 30 minutes, evaporate the water and dry at 105°C to prepare titanium-calcium- Dry sludge gel was placed in a box-type electric furnace an...

Embodiment 3

[0030] A method for preparing a porous titanate adsorbent from acetic acid activated sludge, characterized in that it comprises the following process steps:

[0031] Take 1000g of newly discharged excess sludge, add 400mL of water, adjust the water content to 89.3%, put it in a mashing and homogenizing machine, add 600g of glacial acetic acid, and mash and homogenize it for 30min at a stirring speed of 5000r / min, take it out, and place Vibrate in a 300W 40KHz ultrasonic oscillator for 30min, airtight, and soak at 55°C for 20h to obtain a homogeneous acetic acid activated sludge slurry; weigh 1000g of acetic acid activated sludge, and add 1000g of it dropwise under continuous stirring After the addition of tetrabutyl titanate, continue to stir for 30 minutes, then add 298g of limestone powder, stir evenly, heat to 90°C, keep stirring and react for 30 minutes, evaporate the water and dry at 105°C to prepare titanium-calcium- Dry sludge gel was placed in a box-type electric furna...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com