Cellulose based macromolecular cross-linking agent, preparation method thereof and application of cellulose based macromolecular cross-linking agent in preparation of modified gelatin

A technology of macromolecular cross-linking agent and cellulose, which is applied in the application field of making modified gelatin to achieve the effect of improving light blocking performance and hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A kind of synthetic method of novel macromolecular cross-linking agent based on cellulose:

[0050] (1) Synthesis of EDTA dianhydride (EDTAD):

[0051]Weigh 20 g of EDTA disodium salt and dissolve it in 100 ml of water to form a transparent solution, add 1.5 mol / L HCl dropwise during stirring until a white precipitate appears, and filter with suction to obtain EDTA; weigh 18 g of EDTA and 24 ml of acetic anhydride in Suspension was formed in 31 ml of pyridine, magnetically stirred in an oil bath at 65 °C for 24 h, after the reaction was completed, it was washed with distilled water and ether, then suction filtered, and vacuum-dried at 50 °C to obtain white powdery solid EDTA dianhydride (EDTAD).

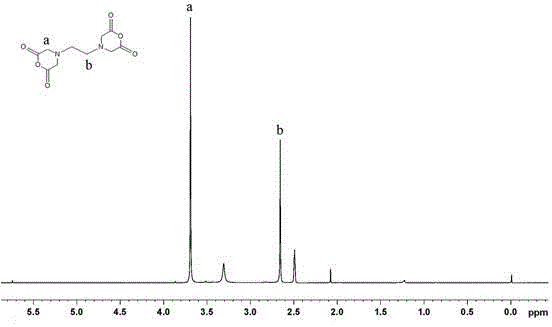

[0052] Such as figure 1 Shown, 1H NMR (400MHz, DMSO): δ 3.691 (s, 8H), 2.657 (s, 4H), 3.08 (s, DMSO), 2.496-2.488 (m, DMSO).

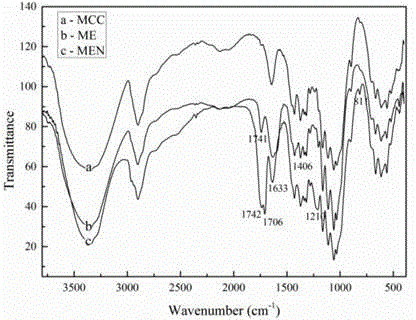

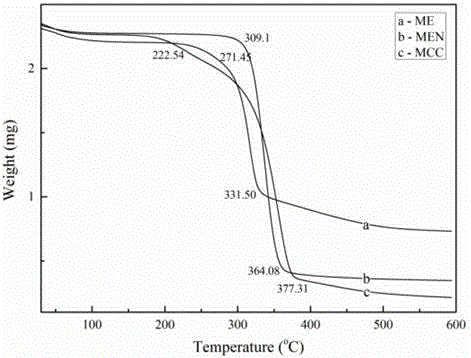

[0053] (2) Preparation of EDTAD functionalized microcrystalline cellulose (ME):

[0054] Weigh 3 g of microcrystalline cellulose (MCC) and 9 g of E...

Embodiment 2

[0072] (1) Synthesis of EDTA dianhydride (EDTAD):

[0073] Weigh 30 g of EDTA disodium salt and dissolve it in 150 ml of water to form a transparent solution, add 1 mol / L HCl dropwise during stirring until a white precipitate appears, and filter with suction to obtain EDTA; weigh 21 g of EDTA and 30 ml of acetic anhydride in Suspension was formed in 40 ml of pyridine, magnetically stirred in an oil bath at 72 °C for 24 h, after the reaction was completed, it was washed with distilled water and then with diethyl ether, then vacuum-dried at 50 °C to obtain white powdery solid EDTA dianhydride (EDTAD).

[0074] (2) Preparation of EDTAD functionalized microcrystalline cellulose (ME):

[0075] Weigh 3 g of MCC and 12 g of EDTAD in 150 ml of DMF, and stir magnetically in an oil bath at 73°C for 30 h. Suction filtration after washing, and vacuum drying at 50°C to obtain a light yellow powdery solid compound, namely, EDTAD functionalized microcrystalline cellulose ME;

[0076] (3) P...

Embodiment 3

[0079] (1) Synthesis of EDTA dianhydride (EDTAD):

[0080] Weigh 40 g of EDTA disodium salt and dissolve it in 200 ml of water to form a transparent solution, add 2 mol / L HCl dropwise during the stirring process until a white precipitate appears, and filter to obtain EDTA; weigh 25 g of EDTA and 40 ml of acetic anhydride in Suspension was formed in 50 ml of pyridine, magnetically stirred in an oil bath at 75 °C for 36 h, after the reaction was completed, it was washed with distilled water and then with ether, then suction filtered, and vacuum-dried at 50 °C to obtain white powdery solid EDTA dianhydride (EDTAD).

[0081] (2) Preparation of EDTAD functionalized microcrystalline cellulose (ME):

[0082] Weigh 3 g of MCC and 10 g of EDTAD in 120 ml of DMF, and stir magnetically in an oil bath at 65 °C for 20 h. Suction filtration after washing, and vacuum drying at 50°C to obtain a light yellow powdery solid compound, namely, EDTAD functionalized microcrystalline cellulose ME; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com