Aliphatic polyester-cyclodextrin poly (pseudo) rotaxane and preparation method thereof

An aliphatic polyester, quasi-polyrotaxane technology, applied in the field of new polymer material preparation, can solve the problems of poor gene compatibility and difficult to meet the requirements of biological tissue regeneration, shorten the absorption period, improve hydrophilicity and biological Compatible, high-yield effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

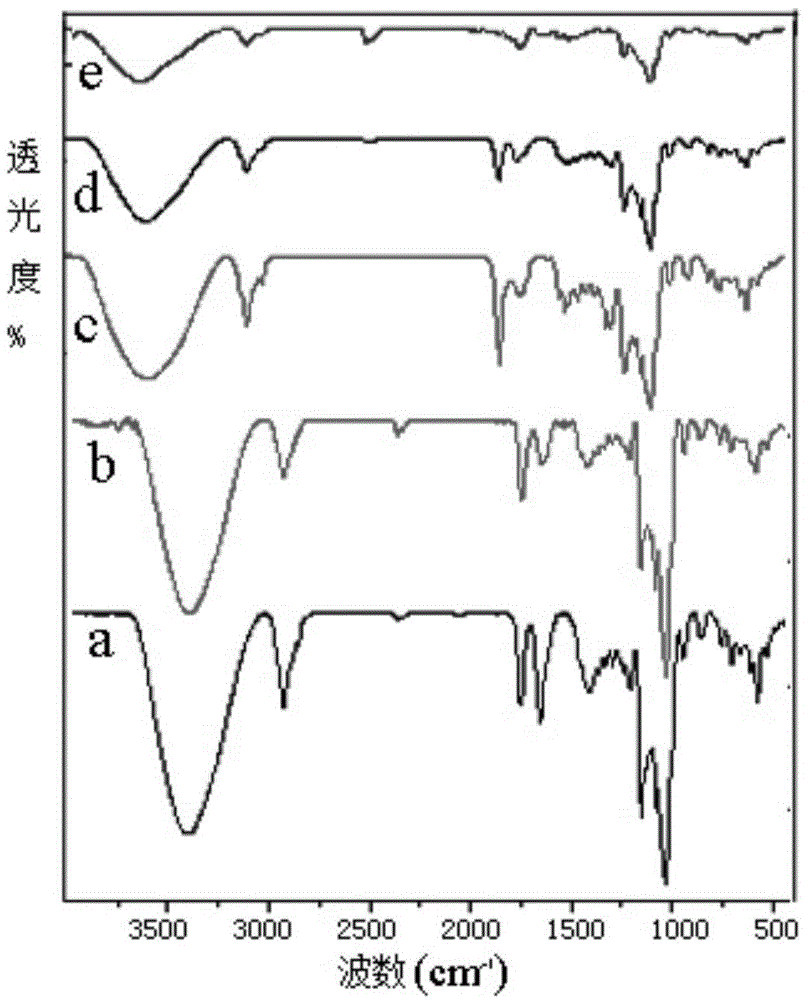

Image

Examples

Embodiment 1

[0026] An aliphatic polyester-cyclodextane precision polyrotaxane, a supramolecular modified polymer formed by polymerizing the main molecule cyclodextrin and biodegradable aliphatic polyester, the main molecule cyclodextrin is α-cyclodextrin Essence, described biodegradable aliphatic polyester is polydioxanone (PPDO), and its preparation method step is as follows:

[0027] 1) Dissolve 0.60g of polydioxanone (PPDO) in 20mL of N,N-dimethylformamide (DMF), stir magnetically at 60°C until completely dissolved, and obtain solution a;

[0028] 2) Dissolve 1.80g of α-cyclodextrin (α-CD) in 30mL of N,N-dimethylformamide (DMF), stir magnetically at 60°C until completely dissolved, and obtain solution b;

[0029] 3) Add solution b dropwise to solution a, react the resulting mixture at 60°C with magnetic stirring for 20 hours, then cool to room temperature, and continue to react for 5 hours. Repeat this high and low temperature reaction process 3 times to obtain fat Polyester-cyclodext...

Embodiment 2

[0034] An aliphatic polyester-cyclodextane precision polyrotaxane, a supramolecular modified polymer formed by polymerizing the main molecule cyclodextrin and biodegradable aliphatic polyester, the main molecule cyclodextrin is α-cyclodextrin Essence, described biodegradable aliphatic polyester is polycaprolactone (PCL), and its preparation method step is as follows:

[0035] 1) Dissolve 0.20g of polycaprolactone (PCL) in 20mL of acetone, and magnetically stir at 50°C until completely dissolved to obtain solution a;

[0036] 2) Dissolve 1.5 g of α-CD in 15 mL of deionized water at 60°C, and magnetically stir at 60°C until completely dissolved to obtain solution b;

[0037] 3) Add solution b dropwise to solution a, react the obtained mixed solution at 60°C under magnetic stirring for 6 hours, then cool to room temperature, continue to react for 10 hours, repeat this high and low temperature reaction process twice to obtain fat Polyester-cyclodextane precision polyrotaxane solu...

Embodiment 3

[0041] An aliphatic polyester-cyclodextane precision polyrotaxane, a supramolecular modified polymer formed by polymerizing the main molecule cyclodextrin and biodegradable aliphatic polyester, the main molecule cyclodextrin is α-cyclodextrin Essence, described biodegradable aliphatic polyester is L-lactide (PLLA, and its preparation method step is as follows:

[0042] 1) Dissolve 0.25g of poly-L-lactide (PLLA) in 50mL of chloroform, and magnetically stir at 40°C until completely dissolved to obtain solution a;

[0043] 2) Dissolve 1.75 g of α-CD in 10 mL of dimethyl sulfoxide (DMSO), stir magnetically at 60°C until completely dissolved, and obtain solution b;

[0044] 3) Add solution b dropwise to solution a, react the obtained mixed solution at 60°C under magnetic stirring for 6 hours, then cool to room temperature, continue to react for 10 hours, repeat this high and low temperature reaction process twice to obtain fat Polyester-cyclodextane precision polyrotaxane solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com