A special alkali-resistant interface agent for phenolic foam insulation board

A phenolic foam and interface agent technology, applied in the chemical industry, can solve the problems of decreased stability of phenolic system, reduced mortar bond strength, poor bond strength, etc., to reduce erosion, reduce water infiltration, and improve flame retardant performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

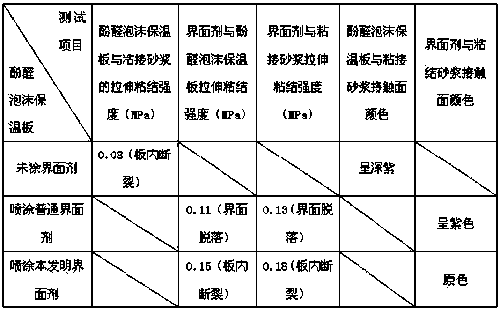

Examples

Embodiment 1

[0041] Equipped with 100kg of the phenolic foam insulation board special alkali-resistant interface agent of the present invention, which is formulated with the following components in weight: 25kg of water, 45kg of modified acrylic emulsion, 4kg of modified hydrophobizing agent, 2kg of dispersant, 2kg of base Material wetting agent, 3kg of silane coupling agent, 2kg of defoaming agent, 3kg of film forming aid, 1kg of antibacterial agent, 4kg of flame retardant, 5kg of inorganic powder, 1kg of multifunctional additives, 2kg Thickener, 1kg color paste.

[0042] Further, the modified acrylic emulsion is a modified styrene-acrylic emulsion. The modified hydrophobic agent is a nano-modified silicone hydrophobic agent. The dispersant is SN5040 dispersant. The substrate wetting agent is polyoxyalkenyl alkyl ethers. The silane coupling agent is KH-570 silane coupling agent. The defoamer is a polyether modified silicon defoamer. The flame retardant is pentaerythritol. The inorganic...

Embodiment 2

[0048] Equipped with 100kg of the phenolic foam insulation board special alkali-resistant interface agent of the present invention, it is formulated with the following components in weight: 20kg of water, 40kg of modified acrylic emulsion, 6kg of modified hydrophobic agent, 2kg of dispersant, 2kg of base Material wetting agent, 3kg of silane coupling agent, 3kg of defoamer, 4kg of film forming aid, 1kg of antibacterial agent, 7kg of flame retardant, 7kg of inorganic powder, 1kg of multifunctional additives, 3kg Thickener, 1kg color paste.

[0049] Further, the modified acrylic emulsion is a modified silicone acrylic emulsion. The modified hydrophobic agent is an inorganic nano material water-based hydrophobic agent. The dispersant is RT8027 dispersant. The substrate wetting agent is polyoxyalkenyl alkyl ethers. The silane coupling agent is KH-570 silane coupling agent. The defoamer is a polyether defoamer. The flame retardant is magnesium hydroxide. The inorganic powder is ...

Embodiment 3

[0055] Equipped with 100kg of the phenolic foam insulation board special alkali-resistant interface agent of the present invention, which is formulated with the following components in weight: 23kg of water, 40kg of modified acrylic emulsion, 5kg of modified hydrophobic agent, 3kg of dispersant, 3kg of base Material wetting agent, 5kg of silane coupling agent, 4kg of defoaming agent, 3kg of film forming aid, 1kg of antibacterial agent, 4kg of flame retardant, 5kg of inorganic powder, 1kg of multifunctional additives, 2kg Thickener, 1kg color paste.

[0056] Further, the modified acrylic emulsion is a vinylidene chloride copolymer emulsion. The modified hydrophobic agent is a nano-modified silicone hydrophobic agent. The dispersant is RT8027 dispersant. The substrate wetting agent is polyoxyalkenyl alkyl ethers. The silane coupling agent is KH-570 silane coupling agent. The defoamer is a polyether defoamer. The flame retardant is graphite. The inorganic powder is mica powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com