Heat-resistant paint and preparation method thereof

A heat-resistant paint and mass-part technology, applied in the field of coatings, can solve the problems of poor flame resistance and low hardness, and achieve the effects of excellent decoration, good heat resistance and good dustproof effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

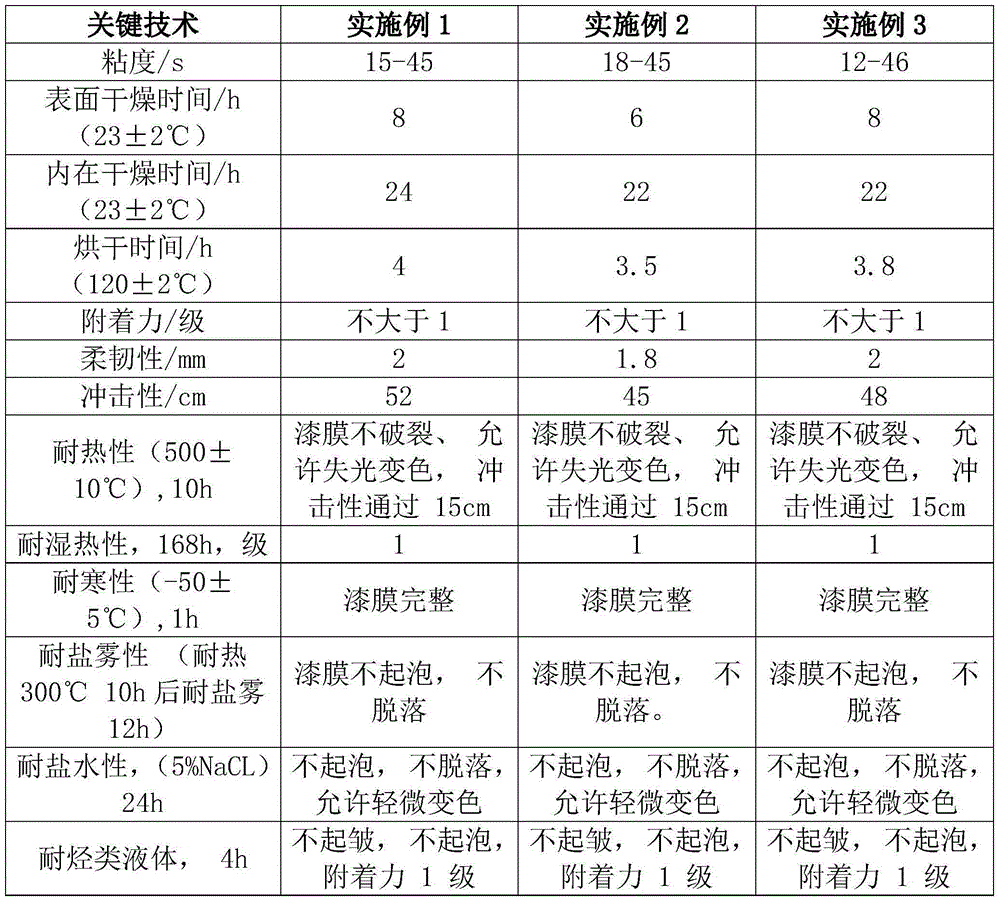

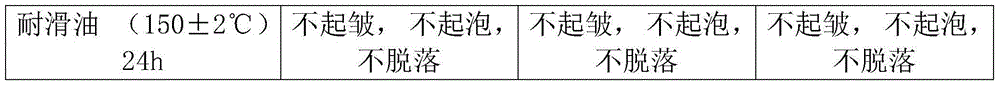

Examples

Embodiment 1

[0023] A heat-resistant paint, the composition of the heat-resistant paint in mass parts is as follows: 8 parts of tung oil, 3 parts of quartz powder, 1 part of aluminum phosphate, 4 parts of polyarylsulfone resin, 4 parts of polyimide resin, 5 parts of butanol , 3 parts of non-isocyanate polyurethane, 2 parts of clay, 2 parts of talcum powder, 5 parts of cobalt isooctanoate, 0.2 parts of anti-settling agent, 8 parts of curing agent, and 2 parts of anti-cracking agent.

[0024] Preferably, the composition of the anti-settling agent in parts by mass is as follows: 20 parts of fumed silica powder, 5 parts of castor oil, 60 parts of ethyl acetate, 2 parts of zinc stearate, and 1.2 parts of modified polyester.

[0025] Preferably, the modified polyester is nano-alumina modified polyesterimide resin.

[0026] Preferably, the curing agent is formed by mixing polyamide, isocyanate and polyurethane in a mass ratio of 1:3:5.

[0027] Preferably, the anti-cracking agent is selected fro...

Embodiment 2

[0029] A kind of heat-resistant paint, the mass parts composition of described heat-resistant paint is as follows: 10 parts of tung oil, 4 parts of quartz powders, 2 parts of aluminum phosphates, 6 parts of polyarylsulfone resins, 7 parts of polyimide resins, 6 parts of butanols , 5 parts of non-isocyanate polyurethane, 3 parts of clay, 3 parts of talcum powder, 7 parts of cobalt isooctanoate, 0.7 parts of anti-settling agent, 15 parts of curing agent, and 4 parts of anti-cracking agent.

[0030] Preferably, the modified polyester is nano-alumina modified polyesterimide resin.

[0031] Preferably, the composition of the anti-settling agent in parts by mass is as follows: 25 parts of fumed silica powder, 8 parts of castor oil, 68 parts of ethyl acetate, 4 parts of zinc stearate, and 3 parts of modified polyester.

[0032] Preferably, the curing agent is formed by mixing polyamide, isocyanate and polyurethane in a mass ratio of 1:3:5.

[0033] Preferably, the anti-cracking agen...

Embodiment 3

[0035] A heat-resistant paint, the composition of the heat-resistant paint in mass parts is as follows: 12 parts of tung oil, 5 parts of quartz powder, 3 parts of aluminum phosphate, 9 parts of polyarylsulfone resin, 9 parts of polyimide resin, 7 parts of butanol , 7 parts of non-isocyanate polyurethane, 4 parts of clay, 4 parts of talcum powder, 8 parts of cobalt isooctanoate, 1.2 parts of anti-settling agent, 18 parts of curing agent, and 6 parts of anti-cracking agent.

[0036] Preferably, the composition of the anti-settling agent in parts by mass is as follows: 30 parts of fumed silica powder, 12 parts of castor oil, 75 parts of ethyl acetate, 6 parts of zinc stearate, and 4.8 parts of modified polyester.

[0037] Preferably, the modified polyester is nano-alumina modified polyesterimide resin.

[0038] Preferably, the curing agent is formed by mixing polyamide, isocyanate and polyurethane in a mass ratio of 1:3:5.

[0039] Preferably, the anti-cracking agent is selected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com