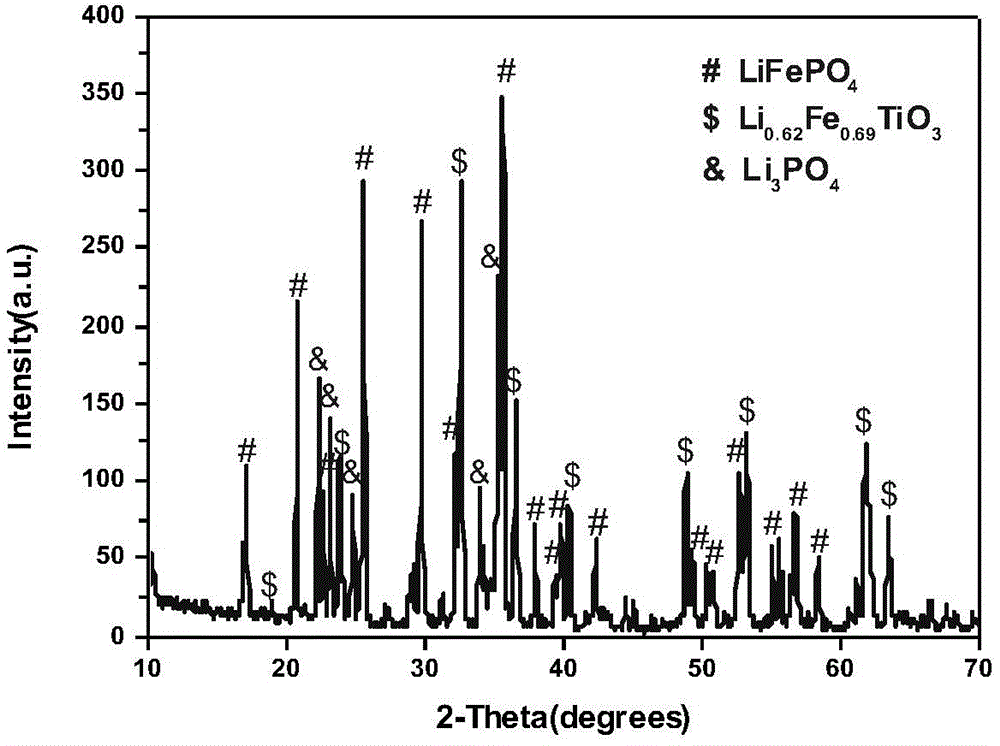

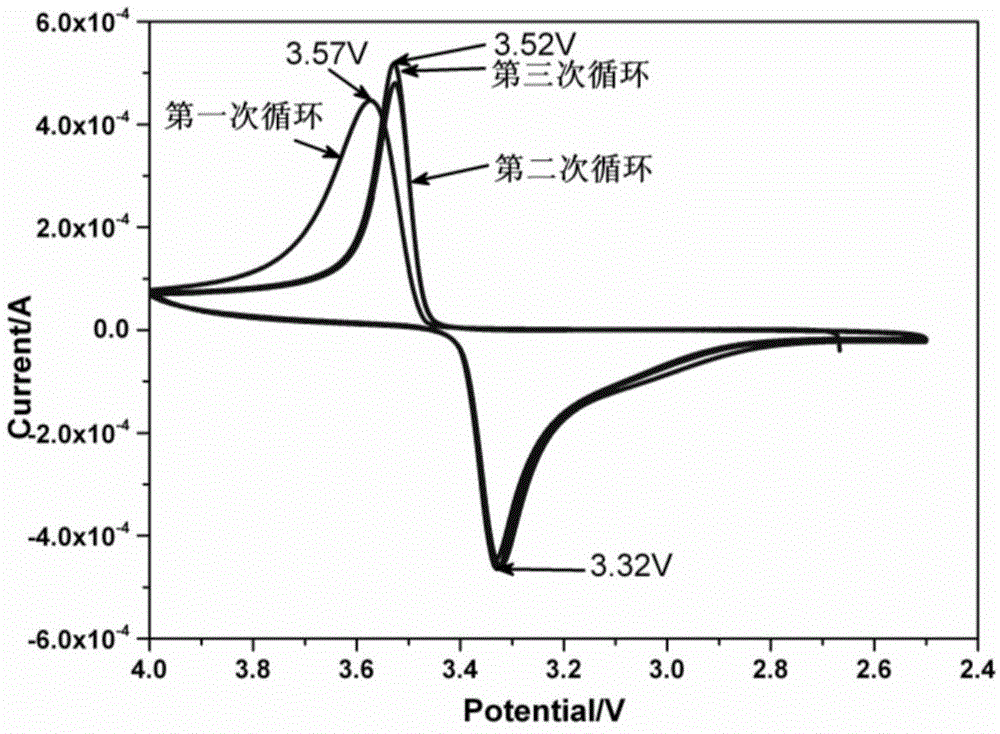

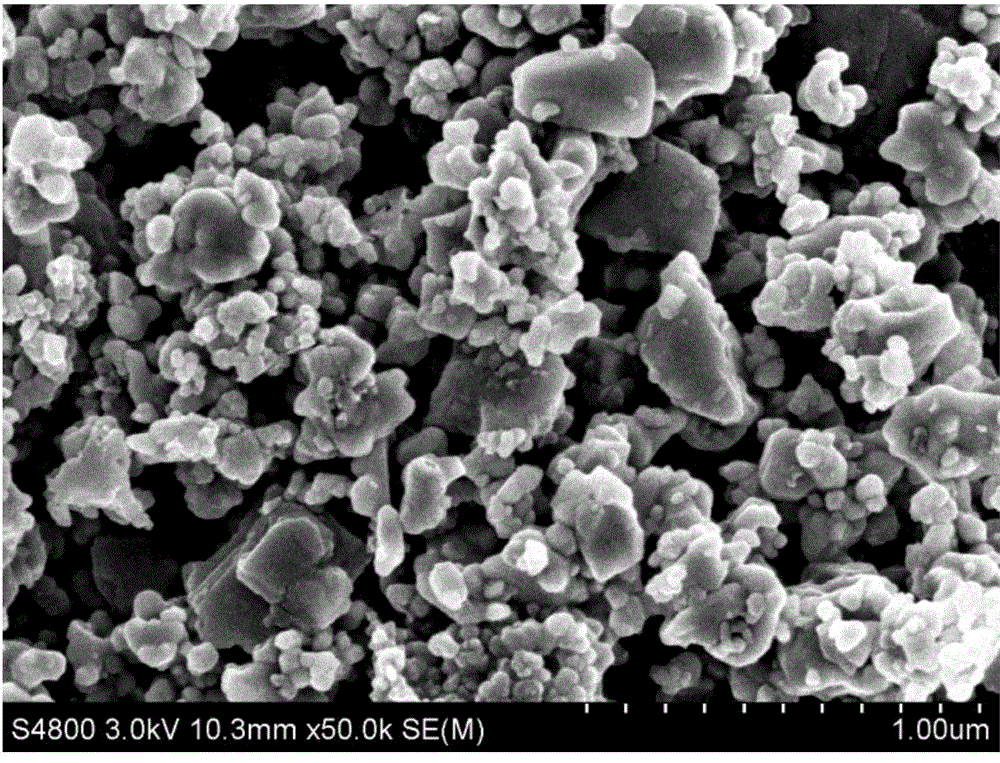

Li<2-2x>FexTiO3/Li3PO4 conjugate coated lithium ion phosphate material as well as preparation method and application thereof

A lithium ferrous phosphate and conjugation technology is applied in the field of positive electrode materials of lithium ion batteries, which can solve the problems of poor controllability, unsatisfactory ion conductivity and electrochemical performance, uneven surface coating, etc. The effect of easy large-scale industrial production and short preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1) According to the molar ratio FeO: LiOH: LiFePO 4 : TiO 2 =0.2:1.85:2.593:1, weigh FeO, TiO 2 The powder and LiOH particles are placed in a high-pressure container, and an appropriate amount of distilled water is added to the high-pressure container according to the volume ratio of water to 50%, fully dissolved, so that Li + The concentration is 2.04mol / L;

[0042] 2) Molar ratio of LiFePO 4 :H 4 N 2 ·H 2 O=0.5:1; Weigh hydrazine hydrate and add it to the mixed slurry in step 1;

[0043] 3) Ultrasonic treatment is performed on the mixed slurry obtained in step 2, the ultrasonic power is 100W, and the ultrasonic time is 5min, until the slurry is evenly mixed and becomes black;

[0044] 4) Seal the uniformly mixed slurry in step 3 in a high-pressure container, place the high-pressure container in an oven at 200° C. for 15 hours, and take it out after cooling to room temperature;

[0045] 5) Put the hydrothermal product obtained in step 4 into an oven and dry at ...

Embodiment 2

[0049] 1) According to the molar ratio FeO: LiOH: LiFePO 4 : TiO 2 =0.4:1.45:2.593:1, weigh FeO, TiO 2 The powder and LiOH particles are placed in a high-pressure container, and an appropriate amount of distilled water is added to the high-pressure container according to the volume ratio of water to 40% to fully dissolve the LiOH. + The concentration is 1.84mol / L;

[0050] 2) Molar ratio of LiFePO 4 :H 4 N 2 ·H 2 O=5:1; Weigh hydrazine hydrate and add it to the mixed slurry in step 1;

[0051] 3) Ultrasonic treatment is performed on the mixed slurry obtained in step 2, the ultrasonic power is 200W, and the ultrasonic time is 1min, until the slurry is evenly mixed and becomes black;

[0052] 4) Seal the uniformly mixed slurry in step 3 in a high-pressure container, place the high-pressure container in an oven and keep it warm at 200°C for 18 hours, and take it out after cooling to room temperature;

[0053] 5) Put the hydrothermal product obtained in step 4 into an oven...

Embodiment 3

[0057] 1) According to the molar ratio FeO: LiOH: LiFePO 4 : TiO 2 =0.7:1.00:0.6:1, weigh FeO, TiO 2 The powder and LiOH particles are placed in a high-pressure container, and an appropriate amount of distilled water is added to the high-pressure container according to the volume ratio of water to 70% to fully dissolve, so that Li + The concentration is 0.50mol / L;

[0058] 2) Molar ratio of LiFePO 4 :H 4 N 2 ·H 2 O=3:1; Weigh hydrazine hydrate and add it to the mixed slurry in step 1;

[0059] 3) Ultrasonic treatment is performed on the mixed slurry obtained in step 2, the ultrasonic power is 200W, and the ultrasonic time is 10min, until the slurry is uniformly mixed and becomes black;

[0060]4) Seal the uniformly mixed slurry in step 3 in a high-pressure container, place the high-pressure container in an oven at 240° C. for 20 hours, and take it out after cooling to room temperature;

[0061] 5) Put the hydrothermal product obtained in step 4 into an oven and dry at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com