Roasting flue gas heat recovery and dust suppression system of zinc oxide production device

A production device, zinc oxide technology, applied in indirect heat exchangers, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of large consumption of consumables, failure to recover heat, waste of energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

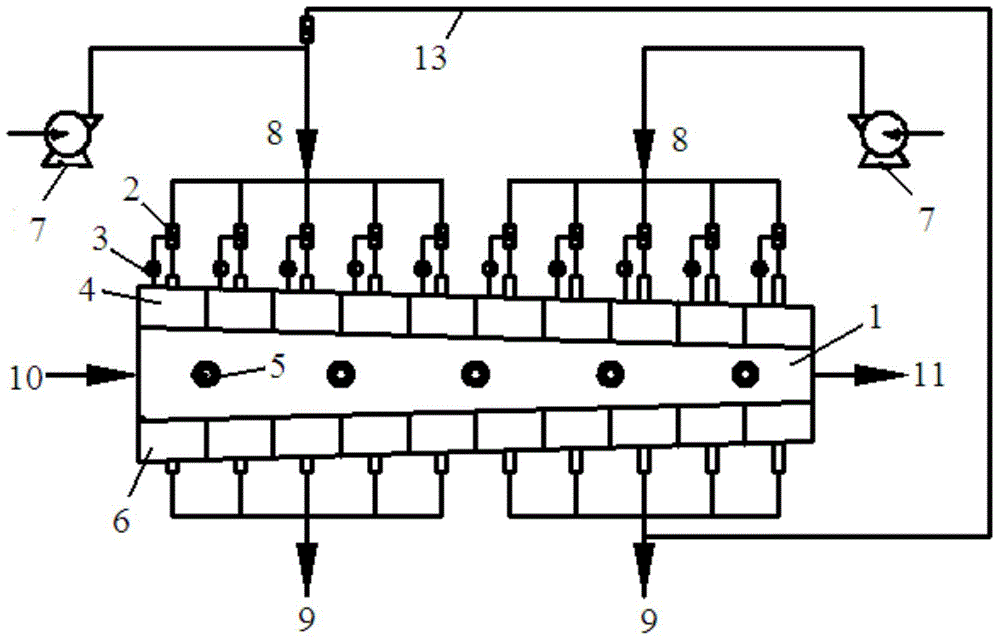

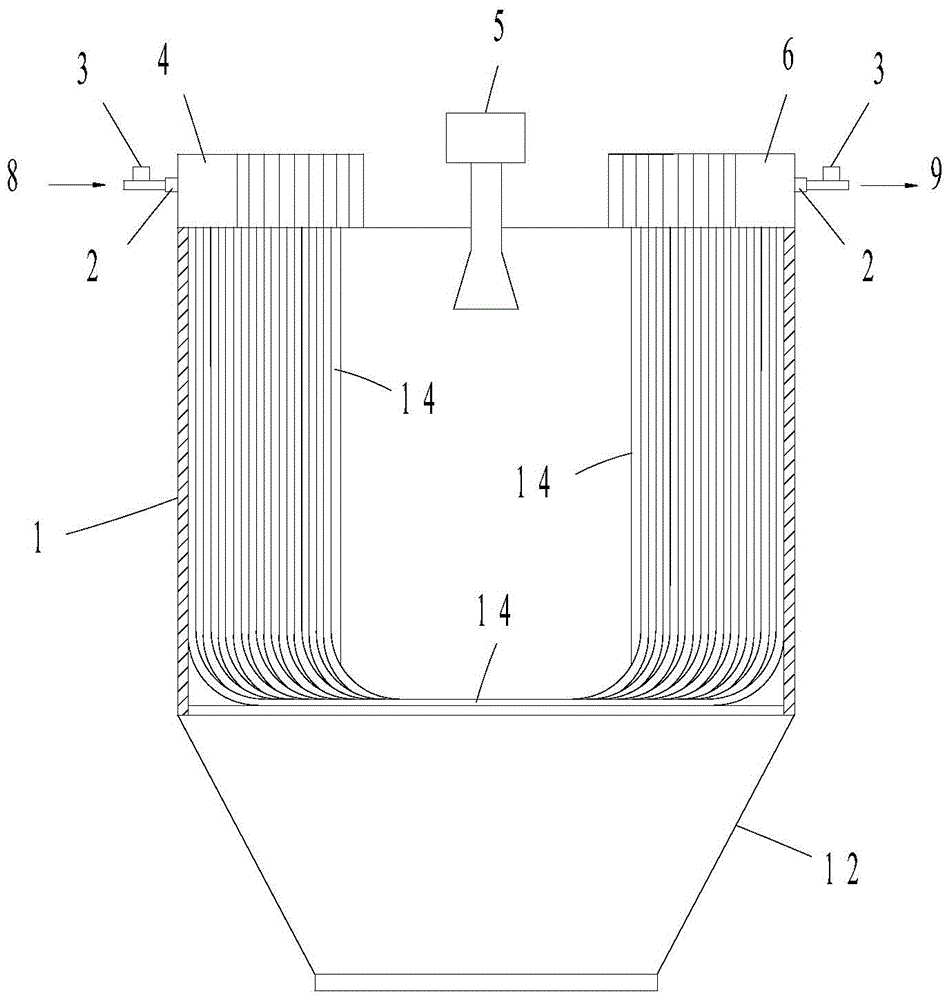

[0036] Such as figure 1 As shown, a zinc oxide production device roasting flue gas heat collection and dust reduction system includes a box body 1, the box body 1 is provided with a flue gas inlet and a flue gas outlet 11, and several heat exchange components are arranged longitudinally on the box body 1 , each heat exchange assembly includes a feed box 4, a discharge box 6, and a number of heat exchange tubes 14 connected to the feed box 4 and the discharge box 6, all heat exchange tubes 14 are located on the inner wall of the box body 1, and each inlet Cooling medium flows into the material box 4 , then circulates to each heat exchange tube 14 , and finally flows out of the material box 6 .

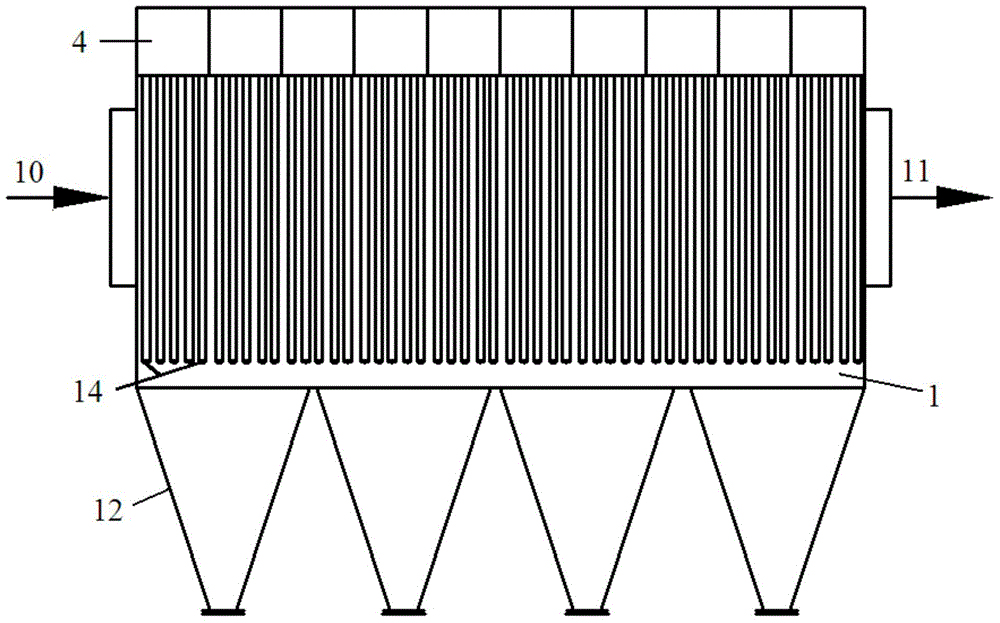

[0037] Such as figure 2 As shown, each of the above-mentioned heat exchange tubes 14 is U-shaped and arranged on the inner wall of the box body 1 along the transverse direction. The boxes 6 are all arranged on the top of the box body 1. This way of vertically hanging the heat exchang...

Embodiment 2

[0046] Such as Figure 1-3 As shown, a zinc oxide production device roasting flue gas heat collection and dust reduction system, ten sets of heat exchange components are installed on the box body 1, each set of heat exchange components includes five heat exchangers, the box body 1 is a cylindrical cross-section with variable diameter body.

[0047] The temperature of the flue gas from the settling chamber of the production of zinc oxide by the volatilization method is 250-700 ° C, SO 2 Content 4000~10000mg / Nm 3 , soot content 13~40g / Nm 3 , the flue gas enters the box body 1 through the flue gas inlet 10, and the heat exchange tubes 14 suspended in the box body 1 sequentially cool the flue gas, and the flue gas passes through each group of heat exchange tubes 14 to cool down. The temperature difference is determined by the particles of zinc oxide powder The pick-up speed and the flue gas working condition flow rate are jointly determined, and the flue gas working condition f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com