Graphene oxide doped molecular imprinted polymer stirring rod as well as preparation method and application thereof

A technology of molecular imprinting and graphene, which is applied in chemical instruments and methods, and other chemical processes, can solve the problems of small adsorption capacity and poor water phase recognition ability of molecular imprinted polymer coatings, and achieve high adsorption capacity and improved water quality. Phase recognition ability, effect of improving adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

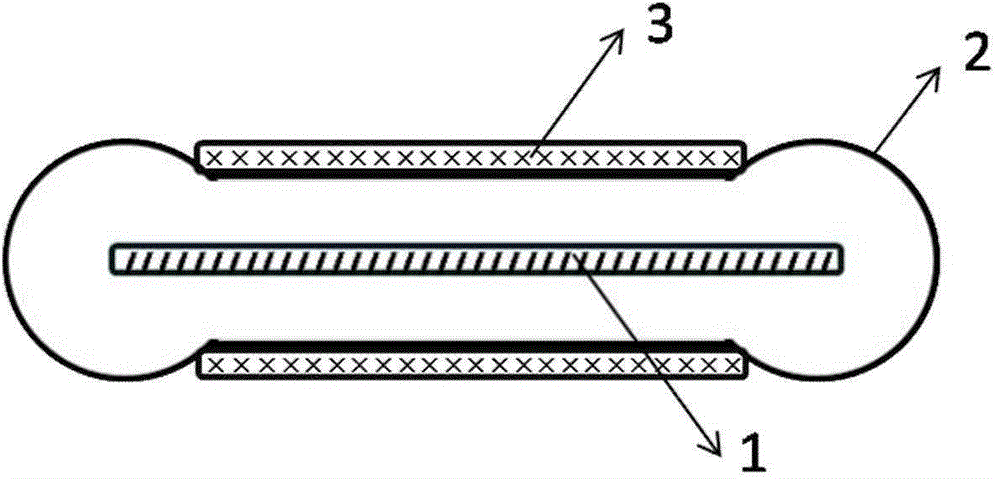

[0042] (1) Design of PTFE mold

[0043] The polytetrafluoroethylene mold for preparing graphene oxide-doped molecularly imprinted polymer-coated stirring rods consists of three parts: the bottom cover, the main body and the upper cover. The bottom cover is not perforated, and the center of the upper cover is perforated for fixing the glass. The capillary rod is in the center of the mold. The inner diameter of the main part of the mold can be adjusted to obtain GO / MIP coating stirring rods with different coating thicknesses. The length of the mold selected in this example is 2cm, the inner diameter of the main part is 2.5mm, and the outer diameter of the glass capillary rod is 1.1mm, and the thickness of the coating of the stirring rod is calculated to be 700μm.

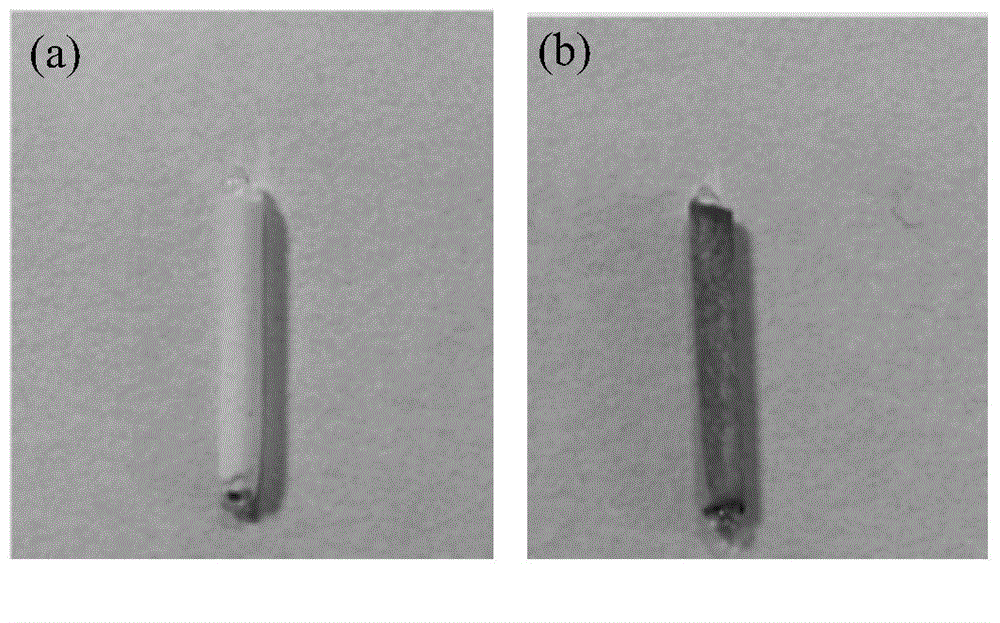

[0044] (2) Activation of glass capillary rod

[0045] Cut the glass capillary to about 6 cm, seal one end with the flame of an alcohol lamp, and melt the other end into a spherical shape to obtain a glass capillary ...

Embodiment 2

[0057] The stirring rod extraction and desorption process of the graphene oxide-doped molecularly imprinted polymer stirring rod is as follows: the graphene oxide-doped molecularly imprinted polymer stirring rod is placed in 10 mL of the sample solution (adjust the pH of the sample solution to 9.0 with sodium hydroxide solution) , stirring and extracting at 800rpm for 40min, after the extraction, take out the stirring rod, wipe off the solution residue on the surface of the stirring rod with filter paper, transfer it to a solution containing 100μL methanol / 10mmol / L hydrochloric acid (60 / 40, v / v) Ultrasonic desorption in the desorption tube for 20min. The desorbed liquid is filtered through a 0.22 μm filter membrane and used for subsequent high-performance liquid chromatography-ultraviolet (HPLC-UV) detection and analysis; the desorbed stirring bar is placed in 8% acetic acid methanol solution and methanol for 5 minutes, and can be repeated after regeneration. use.

[0058] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com