a la 3 ga 5 sio 14 Preparation method of thin film

A technology of thin film and ethanol solution, which is applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems affecting the performance of surface acoustic wave devices, loose film grains, etc. Density, the effect of solving the loose grain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

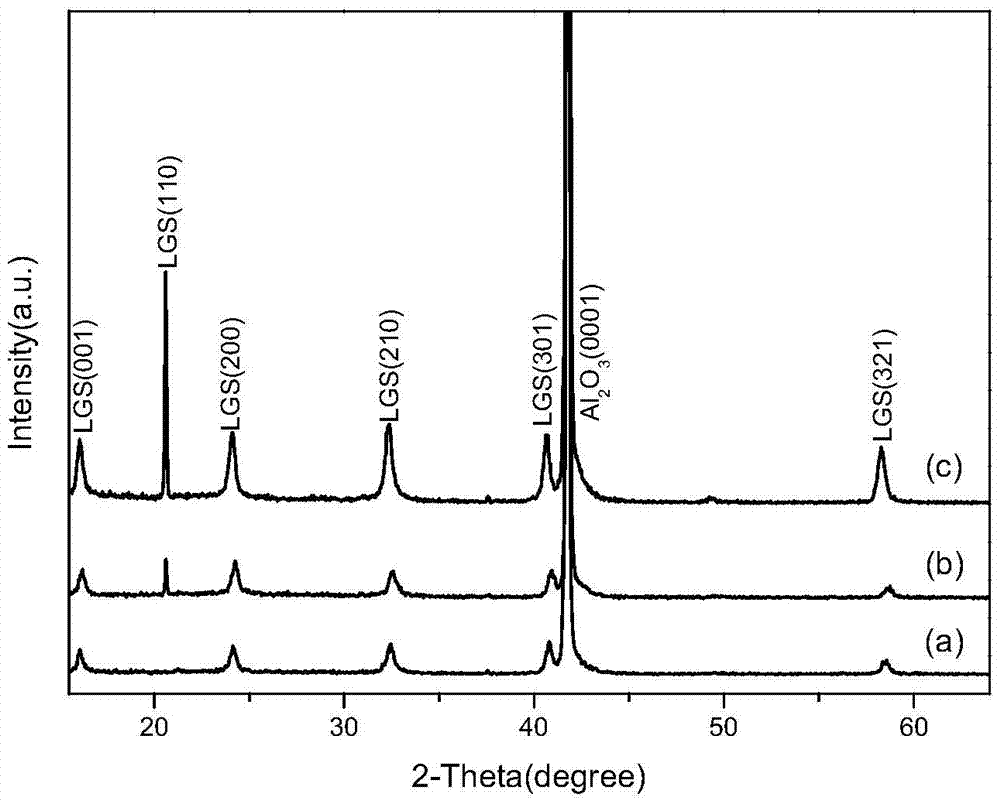

[0023] A La 3 Ga 5 SiO 14 The preparation method of thin film, comprises the following steps:

[0024] Step 1: La(NO 3 ) 3 ·6H 2 O grains were added to absolute ethanol, and stirred at 40-80°C for 10-30 minutes to completely dissolve the grains to obtain clear and transparent La(NO 3 ) 3 ethanol solution; the Ga(NO 3 ) 3 Add the grain crystals into absolute ethanol, and stir at 40-80°C for 10-30 minutes to completely dissolve the grain crystals to obtain clear and transparent Ga(NO 3 ) 3 ethanol solution; Add tetraethyl orthosilicate (TEOS) into absolute ethanol and stir to obtain a clear and transparent ethanol solution of TEOS; then La(NO 3 ) 3 ethanol solution and Ga(NO 3 ) 3 Mix the ethanol solution of citric acid and the ethanol solution of TEOS into the above mixed solution under stirring conditions at a temperature of 50-80°C, and then stir at 50-80°C for 12-24 hours to obtain a precursor sol; , citric acid and La(NO 3 ) 3 ·6H 2 The molar ratio of O is ...

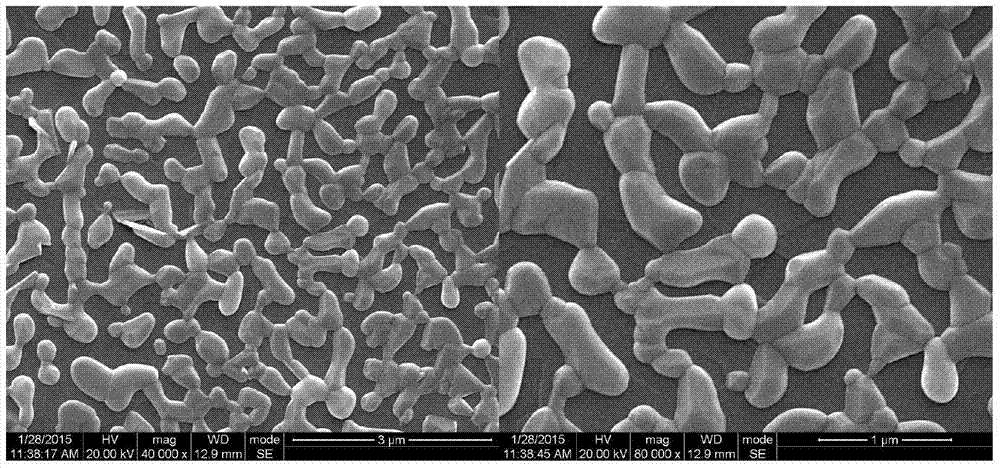

Embodiment 1

[0029] A La 3 Ga 5 SiO 14 The preparation method of thin film, comprises the following steps:

[0030] Step 1: Add 2.6g La(NO 3 ) 3 ·6H 2 O crystals were added to 30 mL of absolute ethanol, and stirred at 60°C for 15 min to completely dissolve the crystals to obtain clear and transparent La(NO 3 ) 3 ethanol solution; 2.56gGa(NO 3 ) 3 Add the grain crystals into 50 mL of absolute ethanol, and stir at 60°C for 15 min to completely dissolve the grain crystals to obtain clear and transparent Ga(NO 3 ) 3 ethanol solution; add 0.42g tetraethyl orthosilicate (TEOS) into 10mL absolute ethanol, stir to obtain a clear and transparent ethanol solution of TEOS; then La(NO 3 ) 3 ethanol solution and Ga(NO 3 ) 3 Mix the ethanol solution of TEOS, add 4.61g of citric acid to the above mixture under stirring conditions at 60°C, stir to dissolve, then slowly add the ethanol solution of TEOS dropwise, after the addition is completed, stir at 60°C for 24h, Obtain precursor sol;

[...

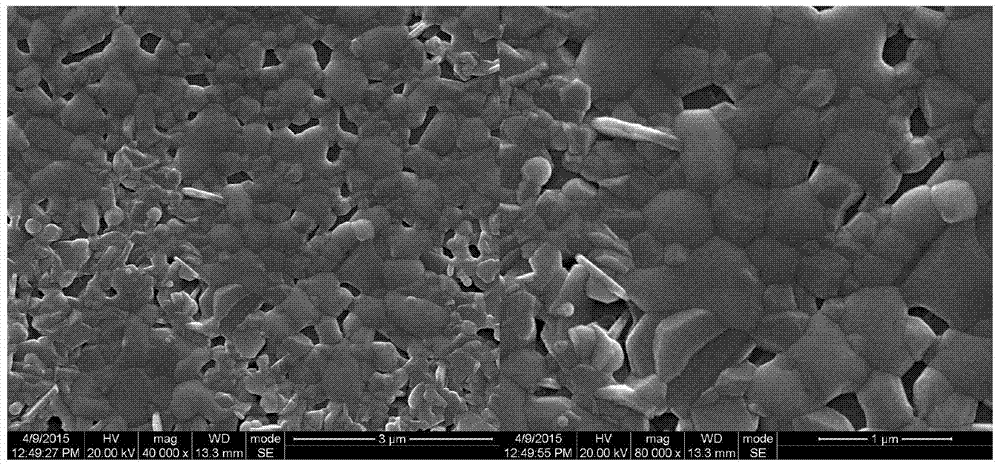

Embodiment 2

[0037] A La 3 Ga 5 SiO 14 The preparation method of thin film, comprises the following steps:

[0038] Step 1: Add 2.6g La(NO 3 ) 3 ·6H 2 O crystals were added to 30 mL of absolute ethanol, and stirred at 60°C for 15 min to completely dissolve the crystals to obtain clear and transparent La(NO 3 ) 3 ethanol solution; 2.56gGa(NO 3 ) 3 Add the grain crystals into 50 mL of absolute ethanol, and stir at 60°C for 15 min to completely dissolve the grain crystals to obtain clear and transparent Ga(NO 3 ) 3 ethanol solution; add 0.42g tetraethyl orthosilicate (TEOS) into 10mL absolute ethanol, stir to obtain a clear and transparent ethanol solution of TEOS; then La(NO 3 ) 3 ethanol solution and Ga(NO 3 ) 3 Mix the ethanol solution of TEOS, add 4.61g of citric acid to the above mixture under stirring conditions at 60°C, stir to dissolve, then slowly add the ethanol solution of TEOS dropwise, after the addition is completed, stir at 60°C for 24h, Obtain precursor sol;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com