Mesoporous silica/carbon dot nanometer composite and preparation method thereof

A technology of mesoporous silica and nanocomposite materials, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of limited application range, toxicity, quenching, etc., and achieve the effect of simple preparation process and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Mesoporous silica / carbon quantum dot nanocomposite material and preparation method thereof, comprising the following steps:

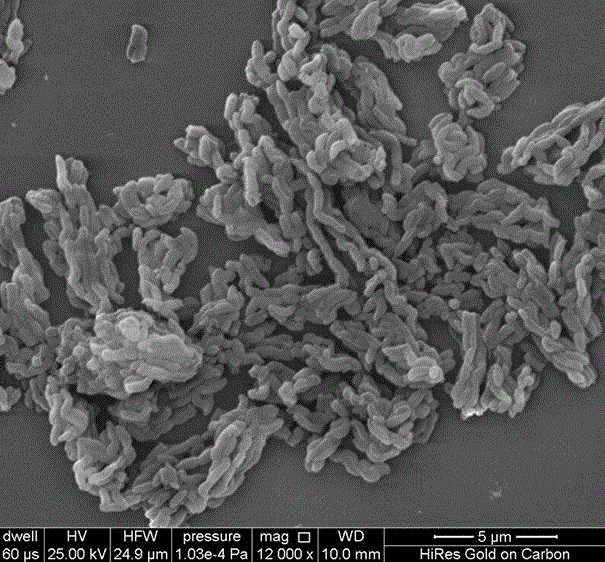

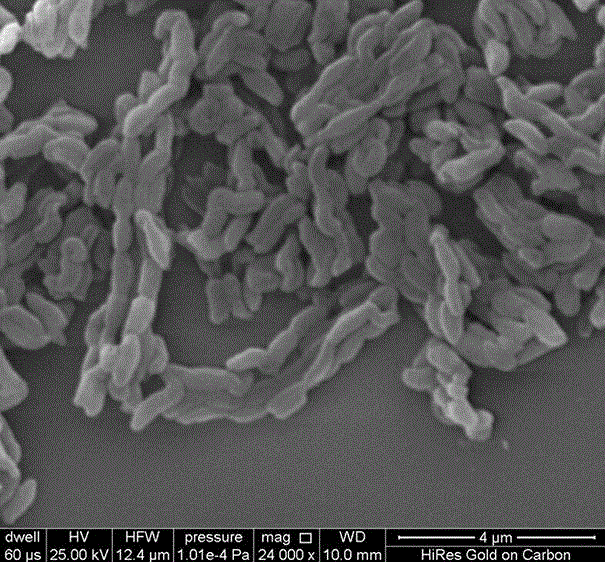

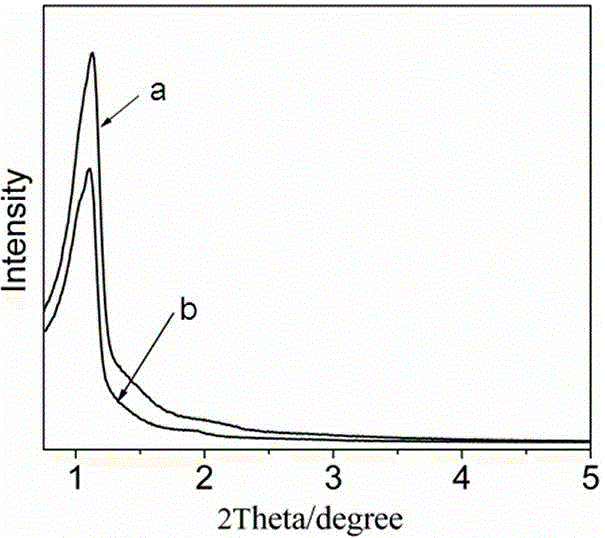

[0027] Step 1, the preparation of mesoporous silica SBA-15, first add 2-3 g triblock copolymer P123 to 100 ml 2.0 mol / L dilute hydrochloric acid, stir in a constant temperature water bath at 30-42 ℃ for 2- After 8 hours, add 4-6 g tetraethyl orthosilicate dropwise during vigorous stirring, and continue stirring at a constant temperature of 30-42°C for 12-24 hours after the dropping, then transfer the mixed solution to an oven at 75-85°C for aging for 12 hours. -24 h, after cooling to room temperature, filter with suction, wash with deionized water until there is no foam, dry at room temperature, and finally heat up to 530-550°C in an air atmosphere and then roast for 5-6 h to obtain a white powdery substance;

[0028] Step 2, preparation of mesoporous silica / carbon quantum dot precursor, adding 0.1-0.2 g of the white powdery substance prepared in...

Embodiment 2

[0036]Step 1, preparation of mesoporous silica SBA-15, preparation of mesoporous silica with nonionic surfactant-triblock copolymer EO 20 PO 70 EO 20 It is a template agent, which is prepared by a typical sol-gel method. The specific preparation process is: take 2-3 g triblock copolymer (P123, Ma≈5800) in a conical flask, add 2.0 mol / L dilute hydrochloric acid 100 mL and 15 mL of deionized water, stirred in a constant temperature water bath at 40°C for 6 h. Add 4-6 g of tetraethyl orthosilicate dropwise under vigorous stirring, and continue stirring at a constant temperature of 40°C for 24 h after the dropping, and then transfer the solution to an oven for aging at 80°C for 24 h. After cooling to room temperature, filter with suction, wash with deionized water until there is no foam, dry at room temperature, and finally heat up to 550 °C for 6 h in an air atmosphere to obtain white powder SBA-15 at a heating rate of 1 o C / min.

[0037] Step 2, preparation of mesoporous si...

Embodiment 3

[0041] Step 1, preparation of mesoporous silica SBA-15, preparation of mesoporous silica with nonionic surfactant-triblock copolymer EO 20 PO 70 EO 20 It is a template agent, which is prepared by a typical sol-gel method. The specific preparation process is: take 2.5 g triblock copolymer (P123, Ma≈5800) in a conical flask, add 100 mL of 2.0 mol / L dilute hydrochloric acid and 20 mL of deionized water, stirred in a constant temperature water bath at 35°C for 8 h. Under vigorous stirring, 5 g of tetraethyl orthosilicate was added dropwise, and after the drop was completed, stirring was continued at a constant temperature of 40 °C for 24 h, and then the solution was transferred to an oven for aging at 75 °C for 20 h. After cooling to room temperature, filter with suction, wash with deionized water until there is no foam, dry at room temperature, and finally heat up to 530 °C in air atmosphere and roast for 6 h to obtain white powder SBA-15 at a heating rate of 2 o C / min.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com