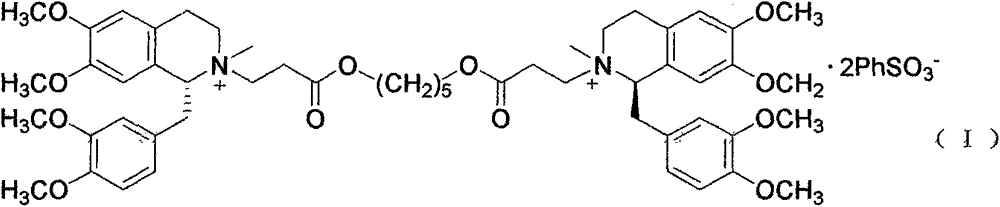

Purification method for cisatracurium besylate

A technology of cisatracurium besylate and besylate, which is applied in the field of pharmaceuticals, can solve the problems of cumbersome post-processing operations, mixing, and difficulty in meeting pharmaceutical needs, shortening the production cycle, reducing pressure, and ensuring reproducibility. present effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1 (preparation of besylate cisatracurium crude product)

[0044] Synthesize the crude product of cisatracurium besylate with reference to the method reported in the published document US 5453510, and the specific operations are as follows:

[0045] Add 1.7Kg of besylate cisatracurium oxalate to 9Kg of water, 19Kg of dichloromethane, adjust the pH to 13-14 with 20% ammonia water, separate the layers, extract the water layer with dichloromethane, combine the organic layers, and wash with water until medium properties, dried over anhydrous sodium sulfate; evaporated to dryness, dissolved the concentrate with 1.4Kg acetonitrile, added 6.3Kg methyl benzenesulfonate, reacted at room temperature for 20 hours, then dropped it into ether, filtered, and dried under reduced pressure to obtain benzenesulfonate Tracuronium crude product. Detecting by HPLC (normalization method) containing cis-cis, cis-trans, the total content of anti-trans atracurium besylate is 96.6%, a...

Embodiment 2

[0046] Embodiment 2 (comparative research)

[0047] Get the cisatracurium besylate crude product 100g that is obtained in Example 1 and dissolve in 1Kg methylene chloride, and load a sample on a 6Kg silica gel (200~300 mesh) column, use benzenesulfonic acid: methylene chloride: methanol The mobile phase of (m / v / v)=1.0:900:100 carries out elution (needs about 250Kg), and liquid phase monitors effluent, and the qualified effluent of merging collection (besylate cisatracurium content is not less than 97 %, the sum of other impurities must not exceed 5%, wherein the single quaternary ammonium salt impurities must not exceed 1.0%, and the content of each isomer is all lower than 0.1%) 100Kg, wash with purified water, concentrate under reduced pressure, add activated carbon for decolorization, filter, The filtrate was dropped into diethyl ether for crystallization, filtered, and vacuum-dried to obtain 52 g of cisatracurium besylate, yield: 26.0%. Detected by HPLC (normalization met...

Embodiment 3

[0049] Get cisatracurium besylate crude product 100g that is obtained by embodiment 1 and be dissolved in the 1Kg dichloromethane (pH=3.5) that contains 4g of besylic acid, then add 3Kg silica gel (200~300 orders), stir to make it well mixed. Concentrate to dryness under reduced pressure at 35°C, and the obtained residue is further dried at 30°C to obtain a silica gel mixture of cisatracurium besylate with uniform content.

[0050] The cisatracurium besylate silica gel carrier prepared above was first soaked with 2 Kg of dichloromethane for 15 minutes, and then filtered. The filter cake is soaked back and forth in the mixed solution of 1Kg methylene chloride and methanol with the percentage by weight of methanol being respectively 2%, 5%, 8%, 10%, 12%, 15%, 20% and 35%. The intervals are 20 minutes. The liquid phase monitors the leachate (filtrate), and the qualified leachate collected in combination (the content of cisatracurium besylate is not less than 97%, the sum of oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com