Preparation method of phytic acid polymer and application of phytic acid polymer in field of metal surface pretreatment

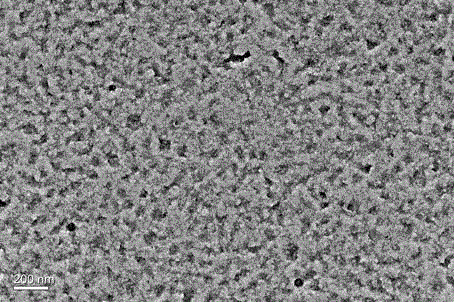

A technology of acid polymer and polymer, which is applied in the direction of chemical instruments and methods, metal material coating technology, compounds of group 5/15 elements of the periodic table, etc., which can solve the problem of poor corrosion resistance and many defective parts of chemical conversion film , Limiting the wide application of phytic acid and other issues, to achieve the effect of good compactness, less defect parts, and improved corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

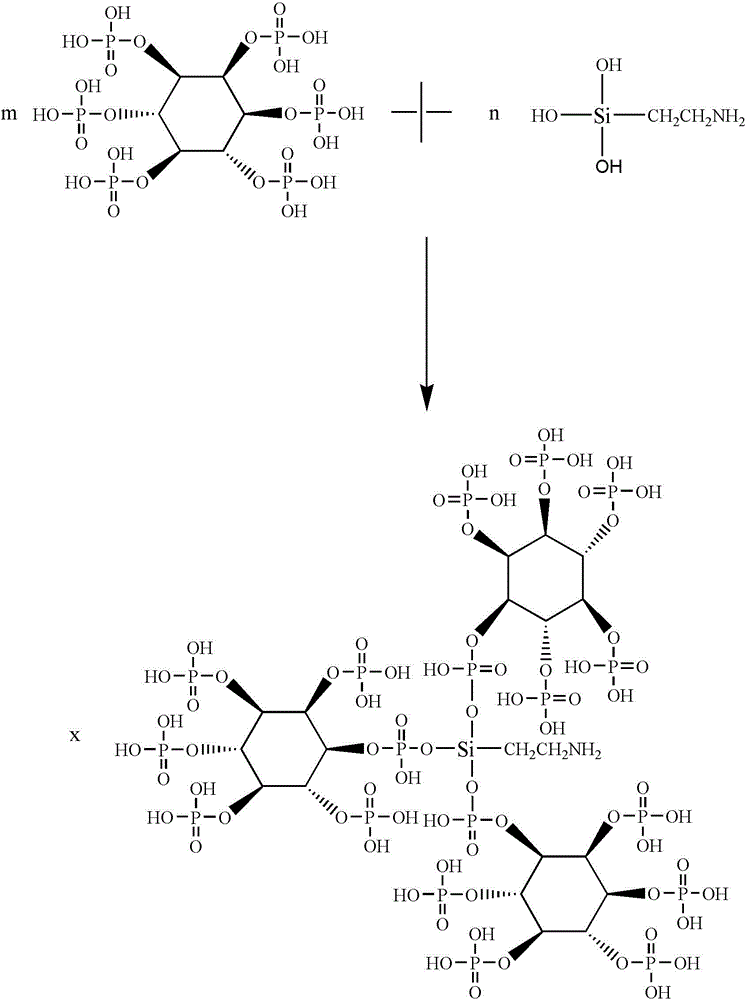

[0020] The synthetic method step of phytic acid polymer of the present invention is as follows: phytic acid is dissolved in water and is mixed with phytic acid solution, and the mass ratio of phytic acid and water is 1-3:100; Silane coupling agent is dissolved in organic solvent, The mass ratio of the silane coupling agent to the organic solvent is 2-6:1000; the mass ratio of the phytic acid to the silane coupling agent is 50-210:1. Heat the phytic acid solution to 55-85°C, add the organic solvent solution of the silane coupling agent dropwise under stirring, and react at constant temperature for 2-5 hours to obtain a slightly white aqueous solution of the phytic acid polymer.

[0021] The organic solvent is an alcohol or ketone solvent, specifically organic solvents such as absolute ethanol, propanol, and acetone.

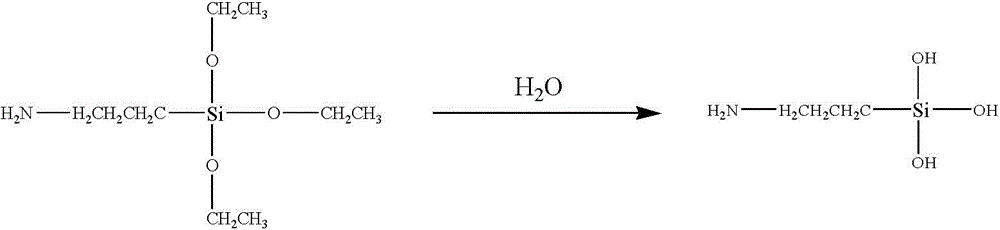

[0022] The organosilane is aminopropyltriethoxysilane, methyltriethoxysilane, γ-(methacryloxy)propyltrimethoxysilane or γ-glycidyl etheroxypropyltrimethoxysilane ...

Embodiment 1

[0026] (1) Synthesis process of phytic acid polymer

[0027] Select aminopropyltriethoxysilane as the selected silane in this embodiment, and take the following steps to synthesize:

[0028] (1) Dissolve 4.85 g of phytic acid in 300 ml of water to obtain a phytic acid solution, and pour it into a 500 ml three-necked flask;

[0029] (2) Weigh 0.0815 g of aminopropyltriethoxysilane, dissolve it in 15.78 g of absolute ethanol, and pour it into a 50 ml constant pressure dropping funnel;

[0030] (3) Heat the three-necked flask containing the phytic acid solution to 75°C with a water bath, then add the ethanol solution of silane dropwise under stirring, and react at constant temperature for 3 h to obtain a slightly white aqueous solution of phytic acid polymer.

Embodiment 2

[0032] (1) Synthesis process of phytic acid polymer

[0033] Select methyltriethoxysilane as the selected silane in this embodiment, and take the following steps to synthesize:

[0034] (1) Dissolve 6.5 g of phytic acid in 300 ml of water to obtain a phytic acid solution, and pour it into a 500 ml three-necked flask;

[0035] (2) Weigh 0.031 g of methyltriethoxysilane, dissolve it in 8 g of acetone, and pour it into a 50 ml constant pressure dropping funnel;

[0036] (3) Heat the three-necked flask containing the phytic acid solution to 60°C with a water bath, then add the ethanol solution of silane dropwise under stirring, and react at constant temperature for 4 h, and finally obtain an aqueous solution of off-white phytic acid polymer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com